Polyimide and preparation method thereof

A technology of polyimide and aromatic diamine, which is applied in the field of preparation of high-performance polymer polyimide, can solve the problem of low dielectric coefficient, poor electrical performance and manufacturing process cost of polyimide containing alicyclic structure Requires high-level problems to achieve the effect of high temperature resistant polyimide film, good solubility, and reduced process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Under the protection of nitrogen, a monomer containing cyclohexane structure and trifluoromethyl substituted aromatic diamine has the following structure:

[0041]

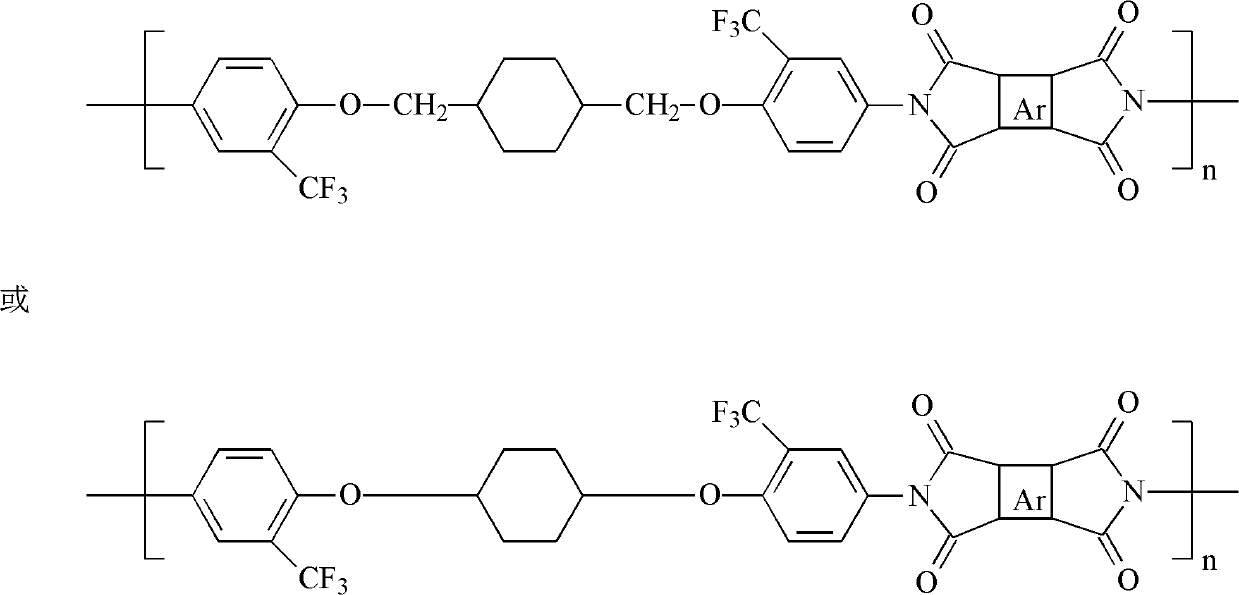

[0042] It is dissolved in N-methylpyrrolidone with benzophenone tetraacid dianhydride in an equimolar ratio to obtain a solution with a total solid mass percentage of 5%, adding isoquinoline (consumption is 2% of the moles of diamine monomer times) as a catalyst, nitrogen flow was introduced to take away the moisture generated during the reaction, after condensation reaction at 110°C for 2 hours, imidization was continued at 205°C for 15 hours, then, the reaction product was poured into ethanol, and the precipitate was collected , dry to obtain floc polyimide solid; the molecular structural formula of described polyimide is:

[0043]

[0044] Among them, Ar is n is 40;

Embodiment 2

[0046] Under the protection of nitrogen, a monomer containing cyclohexane structure and trifluoromethyl substituted aromatic diamine has the following structure:

[0047]

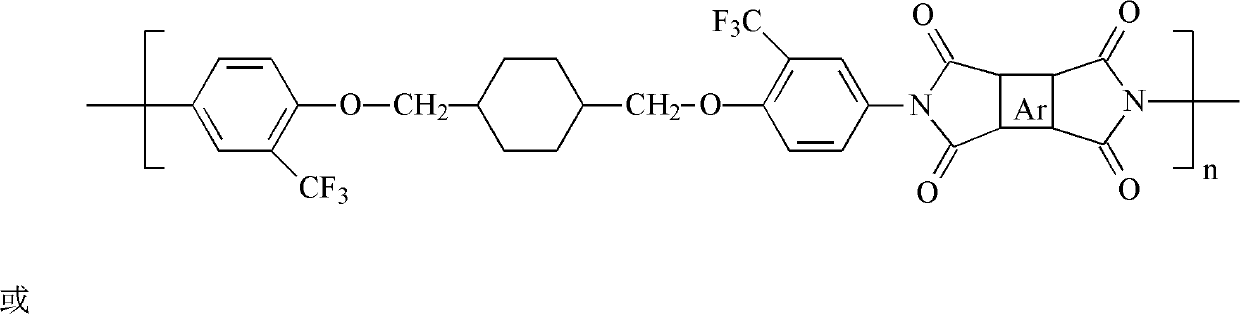

[0048] It is dissolved in N,N-dimethylformamide with biphenyltetralic dianhydride in an equimolar ratio to obtain a solution with a total solid mass percentage of 10%, adding isoquinoline (consumption is diamine monomer moles 4 times of that) as a catalyst, nitrogen flow was introduced to take away the moisture generated during the reaction, after condensation reaction at 90°C for 4 hours, imidization was continued at 190°C for 20 hours, then, the reaction product was poured into ethanol, collected and precipitated Throw out, dry, obtain floc polyimide solid; The molecular structural formula of described polyimide is:

[0049]

[0050] Among them, Ar is n is 30;

Embodiment 3

[0052] Under the protection of nitrogen, a monomer containing cyclohexane structure and trifluoromethyl substituted aromatic diamine has the following structure:

[0053]

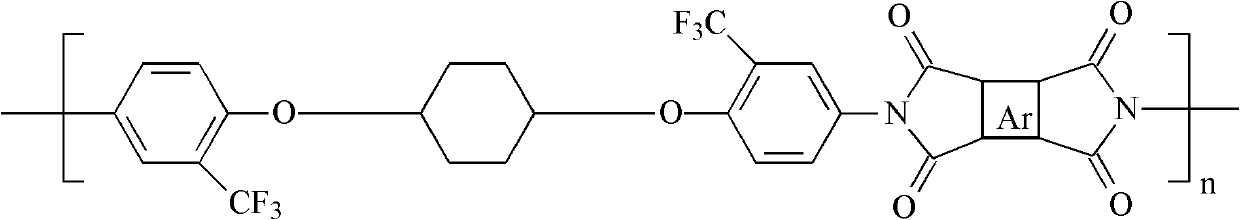

[0054] It is dissolved in N,N-dimethylacetamide with diphenyl ether tetra-acid dianhydride in an equimolar ratio to obtain a solution with a total solid mass percentage of 15%, adding isoquinoline (consumption is diamine monomer mole 3 times the number) as a catalyst, nitrogen flow was introduced to take away the moisture generated during the reaction, after condensation reaction at 95°C for 3 hours, imidization was continued at 200°C for 10 hours, and then the reaction product was poured into methanol and collected The precipitate is separated out and dried to obtain the flocculent polyimide solid; the molecular structural formula of the polyimide is:

[0055]

[0056] Among them, Ar is n is 50;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com