Photoanode decoration material of dye sensitized solar cell

A technology of solar cells and dye sensitization, applied in the field of photoanode modification of dye-sensitized solar cells, can solve the problems of unsatisfactory battery stability and high polyester price, and achieve the effects of low cost, increased efficiency and high battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

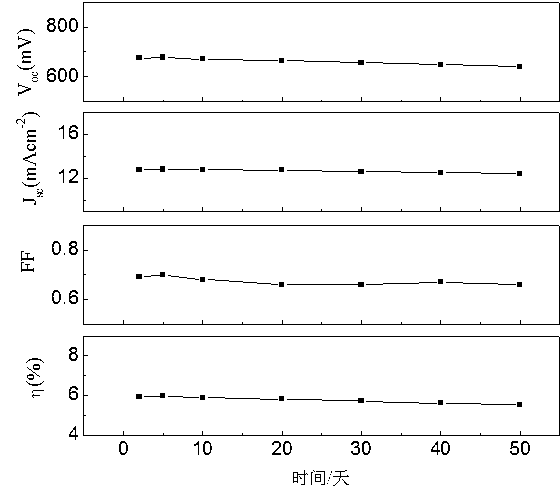

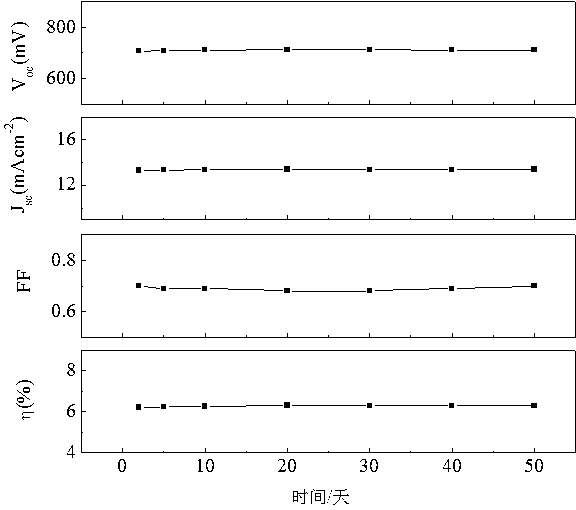

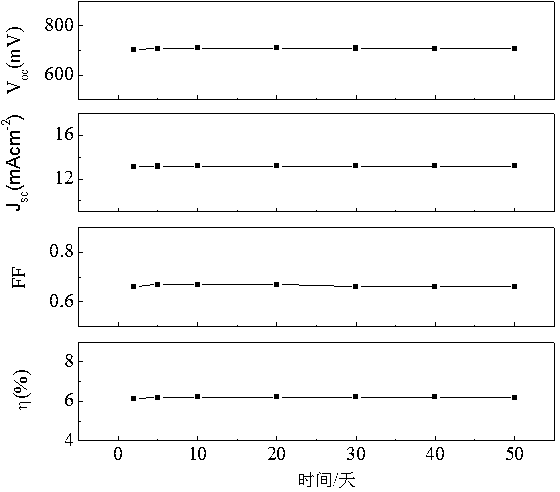

Image

Examples

Embodiment 1

[0027] Siloxane Ionic Liquid 1 Synthesis of: 9.94g and 4.11g React for 24 hours at 80°C under a nitrogen atmosphere. After the product is cooled to room temperature, wash it with ether for 5 times and put it in a vacuum pump to remove excess solvent. 1 H NMR The analyzed data is shown below.

[0028] Siloxane Ionic Liquid 2 Synthesis: take 2.81g With 3.45g LiTFSI exchange reaction 48h in acetonitrile at room temperature, precipitate is filtered, and filtrate is put into vacuum pump after rotary evaporation and takes out excess solvent, the obtained product 1 H NMR The analyzed data is shown below.

[0029] Siloxane Ionic Liquid 3 Synthesis of: 9.23g and 4.11g React at 80°C for 24 hours under a nitrogen atmosphere. After the product is cooled to room temperature, it is washed with ether for 5 times and placed in a vacuum pump to remove excess solvent. Take 2.67g and 1.36g NaC(CN) 3 In acetone, room temperature was exchanged and reacted for 48h, the preci...

Embodiment 2

[0047] Get each 0.5mM of siloxane ionic liquid 1~9 obtained in embodiment 1, make solution respectively with the ethanol of 20ml, the TiO that has adsorbed dyestuff 2 Conductive glass, soak in the solution for 2h. Rinse with ethanol to remove unadsorbed siloxane ionic liquid, and dry in air. The modified photoanode and Pt counter electrode were assembled into a dye-sensitized solar cell. At room temperature, use a xenon lamp to simulate sunlight with a light intensity of 100mW / cm 2 Under the conditions, the measured battery (effective area 0.16cm 2 ) The photoelectric parameters are shown in the table below.

[0048] The exemplary electrolyte used in this embodiment is: containing 0.1M LiI, 0.05M I 2 , 0.6M 1-propyl-3-methylimidazolium iodide (PMII), 0.5M tert-butylpyridine (TBP) in 3-methoxypropionitrile.

[0049] The manufacturing method of the dye-sensitized solar cell in this embodiment is as follows: the FTO conductive glass is first cleaned, and the FTO conductive g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com