Bamboo charcoal odor-removing antibacterial emulsion paint and preparation method thereof

A latex paint and odor-cleaning technology, applied in latex paint, biocide-containing paints, coatings, etc., can solve the problem of bamboo charcoal powder dispersion that cannot be well solved, the porous adsorption effect of bamboo charcoal cannot be exerted, and it is difficult to control bamboo vinegar liquid Solve problems such as volatilization, and achieve the effects of shortening the occupancy time, excellent freeze-thaw resistance, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

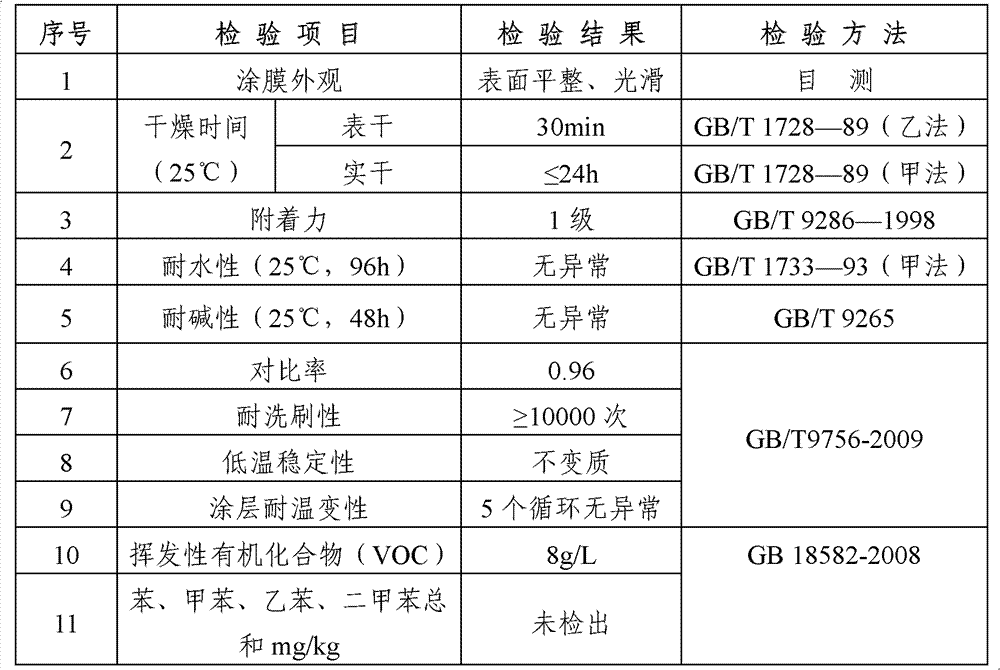

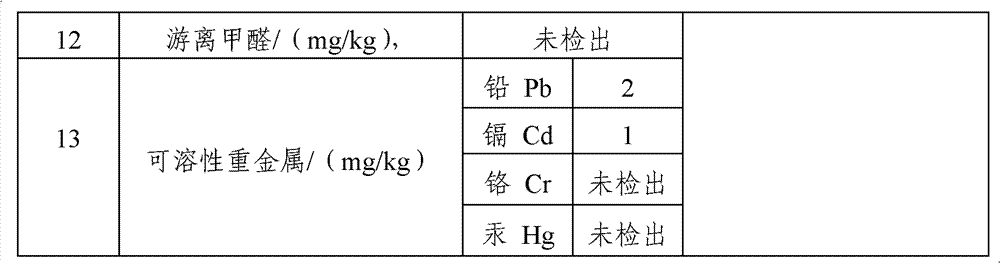

Examples

Embodiment 1

[0051] Embodiment 1: Bamboo charcoal pure taste antibacterial latex paint

[0052] 1. Components:

[0053] BASF styrene-acrylate emulsion ECO560 330g, Corning defoamer SN-1541.5g, Corning defoamer A-10 1.5g, Clariant preservative Nipacide GSF 1.5g, Tego Dispersant TEGO Dispers750W 6g, pigment DuPont Rutile titanium dioxide R-706 250g, filler heavy calcium carbonate 120g, filler calcined kaolin 30g, nano nano fumed silica powder 6g, Rohm and Haas leveling agent RM-20206g, TZY-02 nano inorganic anion additive 15g, polymethacrylic acid-divinylbenzene hollow microspheres 38g, bamboo vinegar 38g, water 150.5g, anionic surfactant 6g.

[0054] 2. Preparation method:

[0055] 1) Mix polymethacrylic acid-divinylbenzene hollow microspheres and bamboo vinegar evenly, add an anionic surfactant, stir for 24 hours, make the bamboo vinegar penetrate into the hollow microspheres, and set aside;

[0056] 2) Mix water, Clariant preservative Nipacide GSF, Tego Dispers 750W and Corning defoame...

Embodiment 2

[0064] Embodiment 2: Bamboo charcoal pure taste antibacterial latex paint

[0065] 1. Components:

[0066] BASF styrene-acrylate emulsion ECO560 300g, Corning defoamer SN-1541.5g, Corning defoamer A-101.5g, Clariant preservative Nipacide GSF 1.0g, Tego dispersant TEGO Dispers750W 6g, heavy filler Calcium carbonate 80g, filler calcined kaolin 70g, pigment Dupont rutile titanium dioxide R-706210g, nano nano fumed silica powder 6g, leveling agent RM-20205g, nano inorganic anion additive 12g, polymethacrylic acid-diethylene Benzene hollow microsphere nanopolymer hollow microsphere 35g, bamboo vinegar liquid 35g, anionic surfactant 5g, water 232g.

[0067] 2. Preparation method:

[0068] 1) Mix polymethacrylic acid-divinylbenzene hollow microspheres and bamboo vinegar evenly, add an anionic surfactant, stir for 24 hours, make the bamboo vinegar penetrate into the hollow microspheres, and set aside;

[0069] 2) Mix water, Clariant preservative Nipacide GSF, Tego Disperser TEGO Di...

Embodiment 3

[0077] Embodiment 3: Bamboo charcoal pure taste antibacterial latex paint

[0078] 1. Components:

[0079] BASF styrene-acrylate emulsion ECO560 250g, defoamer BYK024 1g, defoamer SN154 1.5g, preservative Nipacide GSF 1.5g, dispersant BASF SokalanPA30C 6g, pigment DuPont rutile titanium dioxide R-706 180g, filler heavy carbonic acid Calcium 150g, filler calcined kaolin 80g, hydroxyethyl cellulose 250MBR 3g, leveling agent RM-2020 6g, nano inorganic anion additive 15g, polymethacrylic acid-divinylbenzene hollow microspheres 32g, bamboo vinegar 32g, anion Surfactant 5g, water 237g.

[0080] 2. Preparation method:

[0081] 1) Mix polymethacrylic acid-divinylbenzene hollow microspheres and bamboo vinegar evenly, add an anionic surfactant, stir for 24 hours, make the bamboo vinegar penetrate into the hollow microspheres, and set aside;

[0082] 2) Mix water, preservative Nipacide GSF, dispersant BASF Sokalan PA30C, defoamer BYK024 and defoamer SN154, and stir well;

[0083] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com