A construction method of zno micro/nano material flexible strain sensor

A strain sensor and nanomaterial technology, applied in the construction of ZnO micro/nano material flexible strain sensors, can solve the problems of unsuitability for mass production and complicated operation, and achieve the effects of prolonging life, good crystallinity and overcoming brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

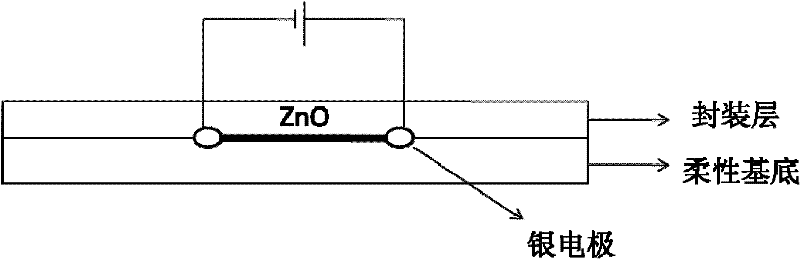

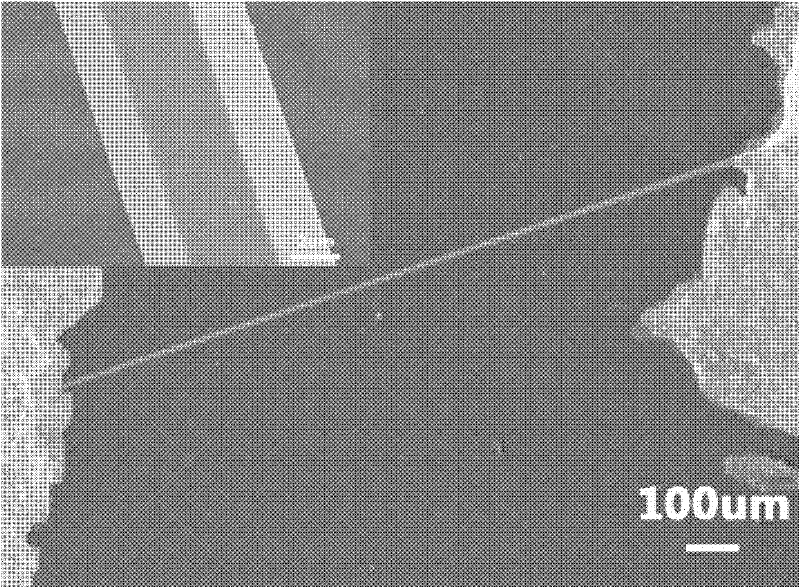

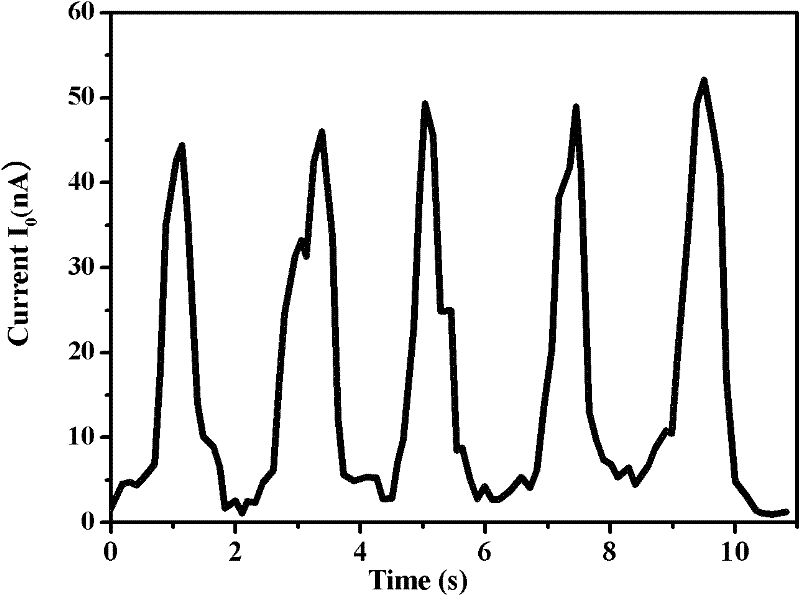

Embodiment 1

[0026] First, the silicon substrate was rinsed with deionized water and alcohol, and dried at 40°C. An 8nm thick gold film was sprayed on the surface of the silicon wafer. Mix Zn powder (purity>99.9%) and C powder at an atomic ratio of 1:1, grind them thoroughly and place them in a porcelain boat, and put the silicon substrate upside down on the porcelain boat. Put the porcelain boat into the middle of the quartz tube in the tube furnace, adjust the flow meter to feed argon: oxygen = 50:1 into the tube. Under this atmosphere, the temperature of the tube furnace was raised to 970° C. and kept for 30 minutes to complete the preparation of the ZnO micro / nano material. Then, the ZnO micro / nano material was dispersed on the silicon wafer, the micro / nanowire ZnO was transferred onto the PDMS substrate by contact printing method, the two ends of the micro / nanowire ZnO were fixed with silver glue, and dried at 120 °C 30min. Finally, the PDMS was coated on the surface of the electro...

Embodiment 2

[0028] First, the silicon substrate was rinsed with deionized water and alcohol, and dried at 40°C. An 8nm thick gold film was sprayed on the surface of the silicon wafer. Mix Zn powder (purity >99.9%) and C powder according to the atomic ratio, grind them thoroughly and place them in a porcelain boat, and put the silicon substrate upside down on the porcelain boat. Put the porcelain boat into the middle of the quartz tube in the tube furnace, adjust the flow meter to feed argon: oxygen = 50:1 into the tube. Under this atmosphere, the temperature of the tube furnace was raised to 970° C. and kept for 30 minutes to complete the preparation of the micro / nano material ZnO. Then, the micro / nano material ZnO was dispersed on the silicon wafer, the micro / nano wire ZnO was transferred to the PI film substrate by contact printing method, the two ends of the micro / nano wire ZnO were fixed with silver glue, and heated at 120 °C. Dry for 30min. Finally, PDMS was coated on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com