A white light led without phosphor powder

A phosphor-free, white light technology, applied in the field of white light LEDs, can solve problems such as difficult control of uniformity and consistency, uneven color of white light, and reduced efficiency, so as to improve energy conversion efficiency and lifespan, improve color rendering index, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

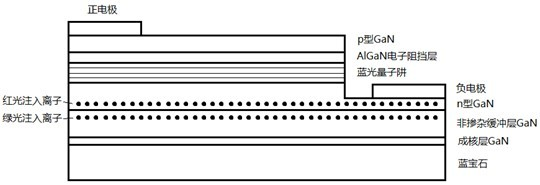

Embodiment 1

[0031] 1. Clean the substrate. The ion-implanted sapphire substrate is ultrasonically cleaned in HCl, acetone, absolute ethanol, and deionized water, and then placed in a reaction furnace;

[0032] 2. Introduce hydrogen (H 2 ) was warming up to 1020°C and cleaned for 3 minutes;

[0033] 3. Grow 30nm low-temperature nucleation layer GaN at 550°C;

[0034] 4. Anneal at 750°C for 5 minutes;

[0035] 5. Grow 2μm non-doped GaN at 1050°C;

[0036] 6. Grow 2μm silicon-doped n-type GaN at 1050°C;

[0037] 7. Out of the oven, cleaned, and implanted with luminous ions, including red-emitting erbium ions (Er 3+ ) or praseodymium ion (Pr 3+ ), the green-emitting erbium ion (Er 3+ ) or cerium ions (Ce 3+ );

[0038] 8. Annealing.

[0039] 9. Grow In for 5 cycles between 700-850 degrees 0.24 Ga 0.76 N 3nm / GaN 10nm blue quantum well;

[0040] 10. Growth of Mg doped 20nm thick Al at 1050°C 0.15 Ga 0.85 N electron blocking layer;

[0041] 11. Grow Mg-doped p-type GaN at 1050°C;...

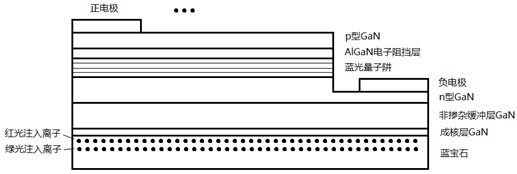

Embodiment 2

[0045] 1. Clean the substrate. The ion-implanted sapphire substrate is ultrasonically cleaned in HCl, acetone, absolute ethanol, and deionized water, and then placed in a MOCVD reactor;

[0046] 2. Introduce hydrogen (H 2 ) was warming up to 1020°C and cleaned for 3 minutes;

[0047] 3. Grow 30nm low-temperature nucleation layer GaN at 550°C;

[0048] 4. Anneal at 750°C for 5 minutes;

[0049] 5. Grow 2μm non-doped GaN at 1050°C;

[0050] 6. Out of the oven, cleaned, and ion-implanted with red erbium ions (Er 3+ ) or praseodymium ion (Pr 3+ );

[0051] 7. At 750°C, MBE grows 2μm silicon-doped n-type GaN;

[0052] 8. Annealing.

[0053] 9. Grow In at 700-850°C for 5 cycles 0.24 Ga 0.76 N 3nm / GaN 10nm blue quantum well;

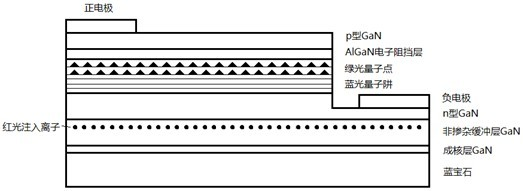

[0054] 10. Take out the sample, clean it, and place it in a molecular beam epitaxy (MBE) reactor;

[0055] 11. At 520°C, grow 5 cycles of InGaN / GaN self-assembled quantum dot layer under the gas flow ratio Ga:In=3:2;

[0056] 12. Growth of Mg doped 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com