Preparation method for carbon nanotube, nickel and aluminum composite powder enhanced polyethylene based composite material

A carbon nanotube, composite powder technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of damaged mechanical properties, complex technology, high price, etc., to achieve comprehensive performance improvement, combined with high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

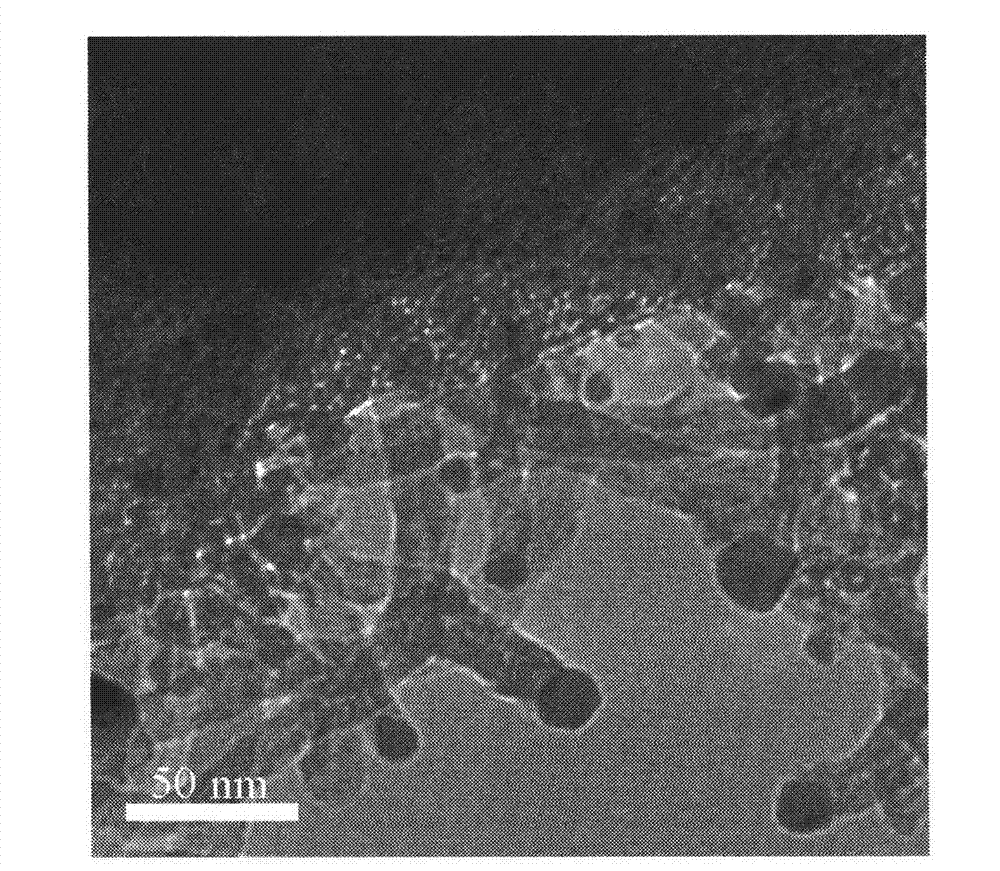

Image

Examples

Embodiment 1

[0017] Add 2.907 grams of nickel nitrate hexahydrate and 55.187 grams of aluminum powder into 1L of deionized water, then add dropwise 500ml of sodium hydroxide solution with a concentration of 0.04mol / L to the above solution under the condition of stirring at 500 rpm with a magnetic stirrer , the reaction produces Ni(OH) with a mass percentage of Ni and Al elements of 1:94 2 / Al binary colloid, and then the prepared binary colloid was dried in a vacuum furnace at 120°C for 6 hours, and calcined in a nitrogen atmosphere at 200°C for 4 hours, and the heating rate of the furnace was 8°C / min, thereby obtaining a NiO / Al catalyst precursor ; Take the obtained NiO / Al and spread it in a quartz boat, and place the quartz boat in the constant temperature zone in the middle of the quartz reaction tube. First, nitrogen is introduced into the reaction tube to remove the air. Feed hydrogen at 200ml / min for 2 hours to reduce NiO / Al to Ni / Al, stop feeding hydrogen, raise the furnace temperat...

Embodiment 2

[0019] The specific method and steps are the same as in Example 1, but the different conditions are: 2.907 grams of nickel nitrate hexahydrate and 55.765 grams of aluminum powder are added to 1L of deionized water, the weight ratio of Ni and aluminum in the Ni / Al catalyst is 1:95, chemical vapor phase The time for depositing CNTs was 15 minutes, and finally a CNTs / Ni / Al composite powder with a mass content of carbon nanotubes of 3.5%, a nickel content of 1%, and an aluminum content of 95.5% was obtained.

Embodiment 3

[0021]The specific method and steps are the same as in Example 1, but the different conditions are: 2.907 grams of nickel nitrate hexahydrate and 54.3 grams of aluminum powder are added to 1L of deionized water, the weight ratio of Ni and aluminum in the Ni / Al catalyst is 1: 92.5, chemical vapor phase The time for depositing CNTs was 45 minutes, and finally a CNTs / Ni / Al composite powder with a mass content of carbon nanotubes of 6.5%, a nickel content of 1%, and an aluminum content of 92.5% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com