Magnetic fluorescent composite microsphere and method for preparing same

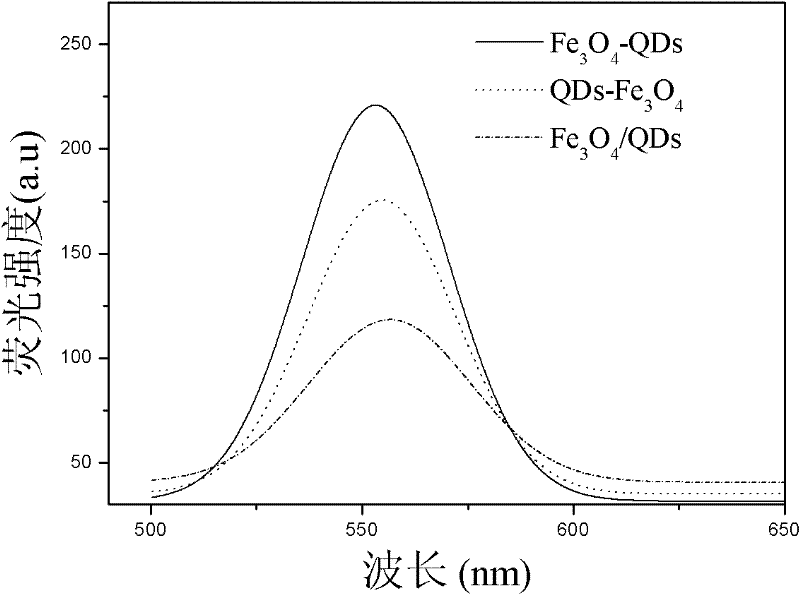

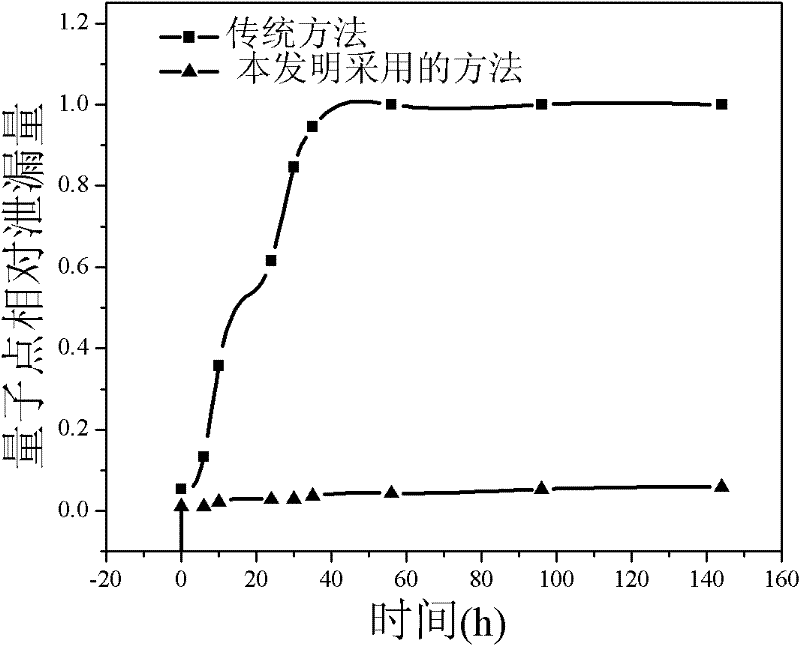

A composite microsphere and magnetic technology, applied in the field of composite materials, can solve problems such as the influence of fluorescent properties of fluorescent substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Take 1mgFe 3 o 4 Magnetic nanoparticles and 10 mg of styrene polymer microspheres with a cross-linking degree of 100% and a particle size of 50 μm were respectively dispersed in 1 ml of chloroform and 10 ml of n-butanol, and the two systems were mixed, dispersed uniformly by ultrasonic, and swelled at room temperature 10 min, centrifuged to prepare magnetic microspheres.

[0028] 2) Disperse 2mg of CdSeTe quantum dots and 10mg of prepared magnetic microspheres in 2ml of chloroform and 12ml of hexadecane respectively, mix the two systems, disperse them uniformly by ultrasonic, and swell at 40°C for 30min;

[0029] 3) The temperature of the reaction system in step 2) is raised to 140° C., and the temperature is kept until there is no reflux of chloroform;

[0030] 4) After the chloroform is completely volatilized, the reaction system is cooled down, centrifuged, washed and then dried to obtain magnetic fluorescent polymer microspheres.

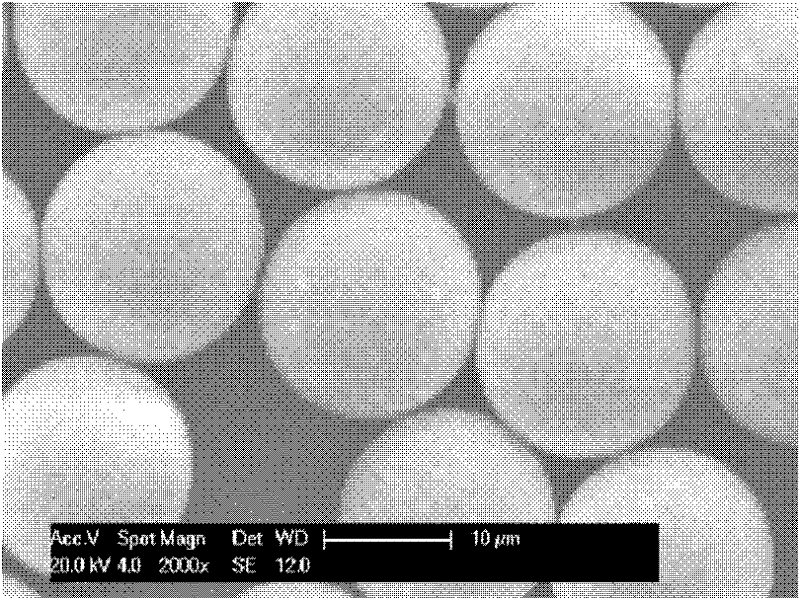

[0031] image 3 Scanning el...

Embodiment 2

[0033] 1) Take 1mgFe 3 o 4 Magnetic nanoparticles and 50 mg of polymethyl methacrylate polymer microspheres with a cross-linking degree of 5% and a particle size of 5 μm were respectively dispersed in 6 ml of cyclohexane and 6 ml of isopropanol, and the two systems were mixed and ultrasonically dispersed uniformly. Swell at room temperature for 120 minutes, and centrifuge to prepare magnetic microspheres.

[0034] 2) Take 1mg of CdSe / ZnSe quantum dots with a fluorescence emission peak at 650nm and 50mg of magnetic microspheres and disperse them in 7ml of cyclohexane and 7ml of octadecene respectively, mix the two systems, disperse them evenly with ultrasound, and swell at 60°C. Swelling time 120min;

[0035] 3) The temperature of the reaction system in step 2) is raised to 240° C., and the temperature is kept until there is no reflux of cyclohexane;

[0036] 4) After the cyclohexane is completely volatilized, the temperature of the reaction system is lowered, centrifuged, w...

Embodiment 3

[0040] 1) Take 1mgFe 3 o 4 Magnetic nanoparticles and 20 mg of polyethyl methacrylate polymer microspheres with a cross-linking degree of 50% and a particle size of 20 μm were respectively dispersed in 1 ml of chloroform and 6 ml of isopropanol, and the two systems were mixed and dispersed uniformly by ultrasonic. Swell at room temperature for 90 minutes, and centrifuge to prepare magnetic microspheres.

[0041] 2) Take 1 mg of CdS quantum dots and 20 mg of magnetic microspheres and disperse them in 3 ml of cyclohexane and 9 ml of hexadecane respectively, mix the two systems, disperse them uniformly by ultrasonic, and swell at 55°C for 60 min;

[0042] 3) The temperature of the reaction system in step 2) is raised to 200° C., and the temperature is kept until there is no reflux of cyclohexane;

[0043] 4) After the cyclohexane is completely volatilized, the temperature of the reaction system is lowered, centrifuged, washed and then dried to obtain magnetic fluorescent polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com