Method and system for carrying out incineration on high N-S-based saliferous organic waste liquor and carrying out purification treatment on tail gas

A technology for purifying organic waste liquid and tail gas, applied in the direction of combustion method, incinerator, combustion type, etc., can solve problems such as bed material agglomeration, fluidization failure, and increased consumption of oxidant, and achieve the effect of reducing operating costs and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition of the high N-S salt-containing organic waste liquid to be incinerated and purified is shown in Table 1 below:

[0028] Table 1

[0029] sample 1

Composition (wt%)

7.38%

Glycyl nitrile

0.97%

Iminodiacetonitrile

13.46%

Nitrilotriacetonitrile

5.14%

16.33%

46.72%

other organic matter

10%

total

100%

[0030] The steps of using the method of the present invention to process the above-mentioned high N-S base salt-containing organic waste liquid are as follows:

[0031] (1) High N-S base salt-containing organic waste liquid and combustion-supporting air enter the incinerator from the top of the "L" type incinerator 4, and the reaction temperature in the incinerator 4 is 1100-1200°C (for example, 1100°C, 1150°C or 1200°C) , in the presence of oxygen, the waste liquid is oxidized and decompose...

Embodiment 2

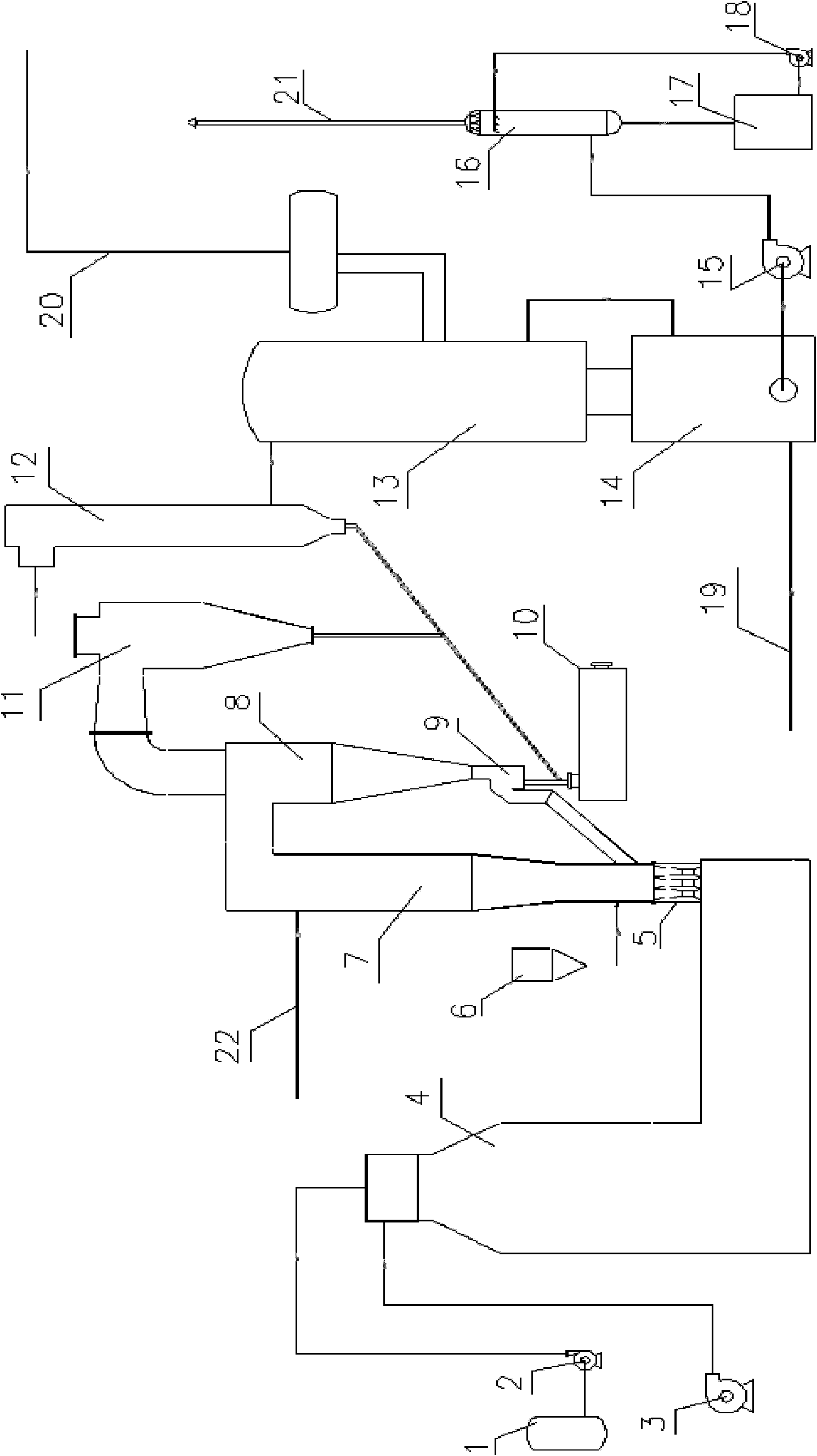

[0037] like figure 1 As shown, the incineration and tail gas purification treatment system of a high N-S base salt-containing organic waste liquid according to the present invention includes a waste liquid incineration system, a flue gas desulfurization and denitrification system, a flue gas dust removal system, a waste heat recovery system and Flue gas scrubbing system;

[0038] The waste liquid incineration system includes an incinerator 4, and the waste liquid supply pipeline and the combustion air supply pipeline are respectively connected to the top plate inlet of the incinerator 4; the starting end of the waste liquid supply pipeline is connected to the waste liquid tank 1, A waste liquid pump 2 is also provided on the waste liquid supply pipeline; a blower 3 is provided on the combustion air supply pipeline;

[0039] The flue gas desulfurization and denitration system includes a flue gas injector 5, a silo 6, a desulfurization and denitrification reactor 7, a separator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com