Cathode of film-free air microbial fuel cell and manufacturing method thereof

A fuel cell cathode and air microorganism technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problem of limiting the practical application of single-chamber air cathode microbial fuel cells, increasing the cost and process complexity of the battery, and the poor power generation performance of the battery. High problems, to achieve the effect of being conducive to long-term operation, superior waterproof effect, and easy to realize industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

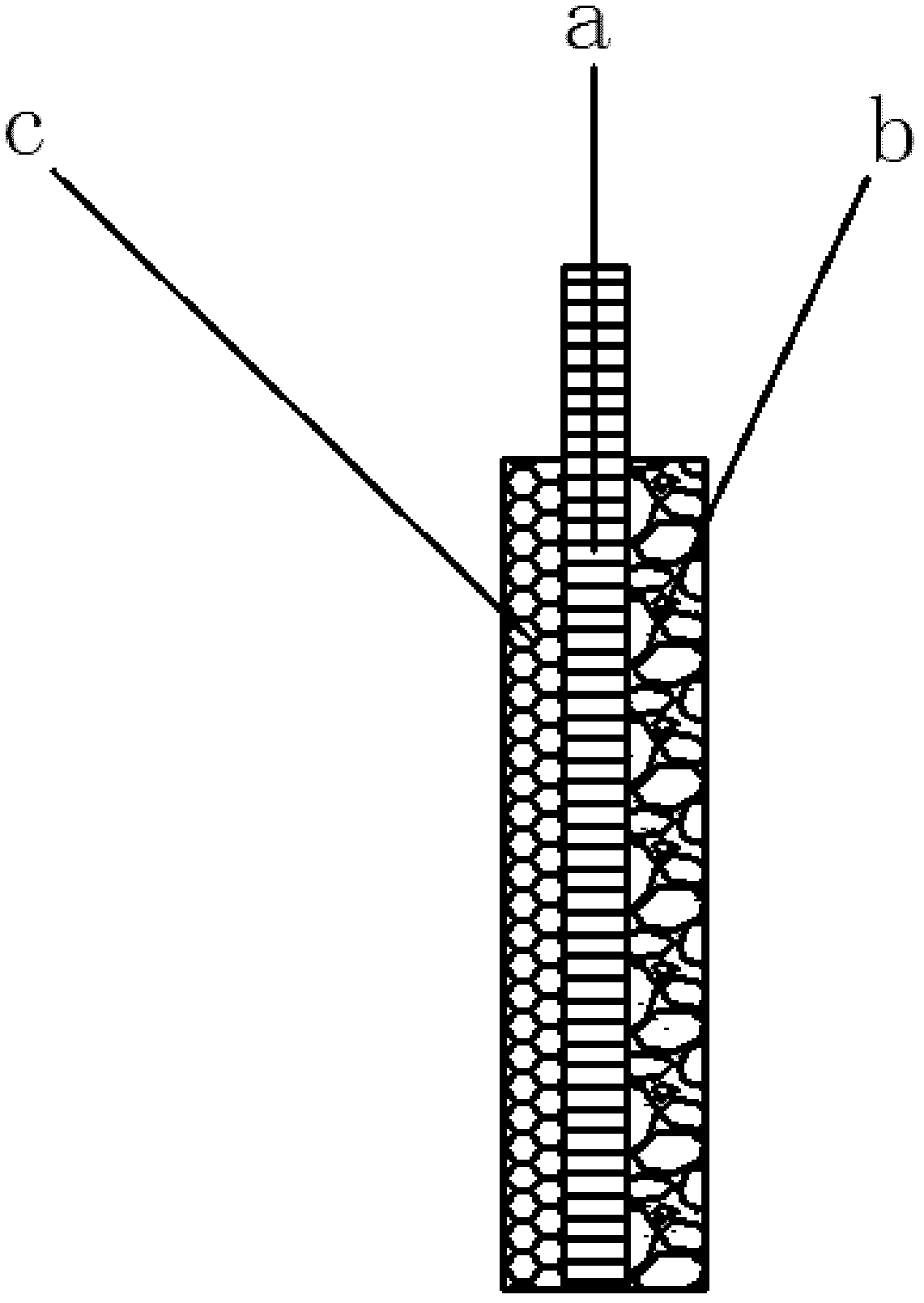

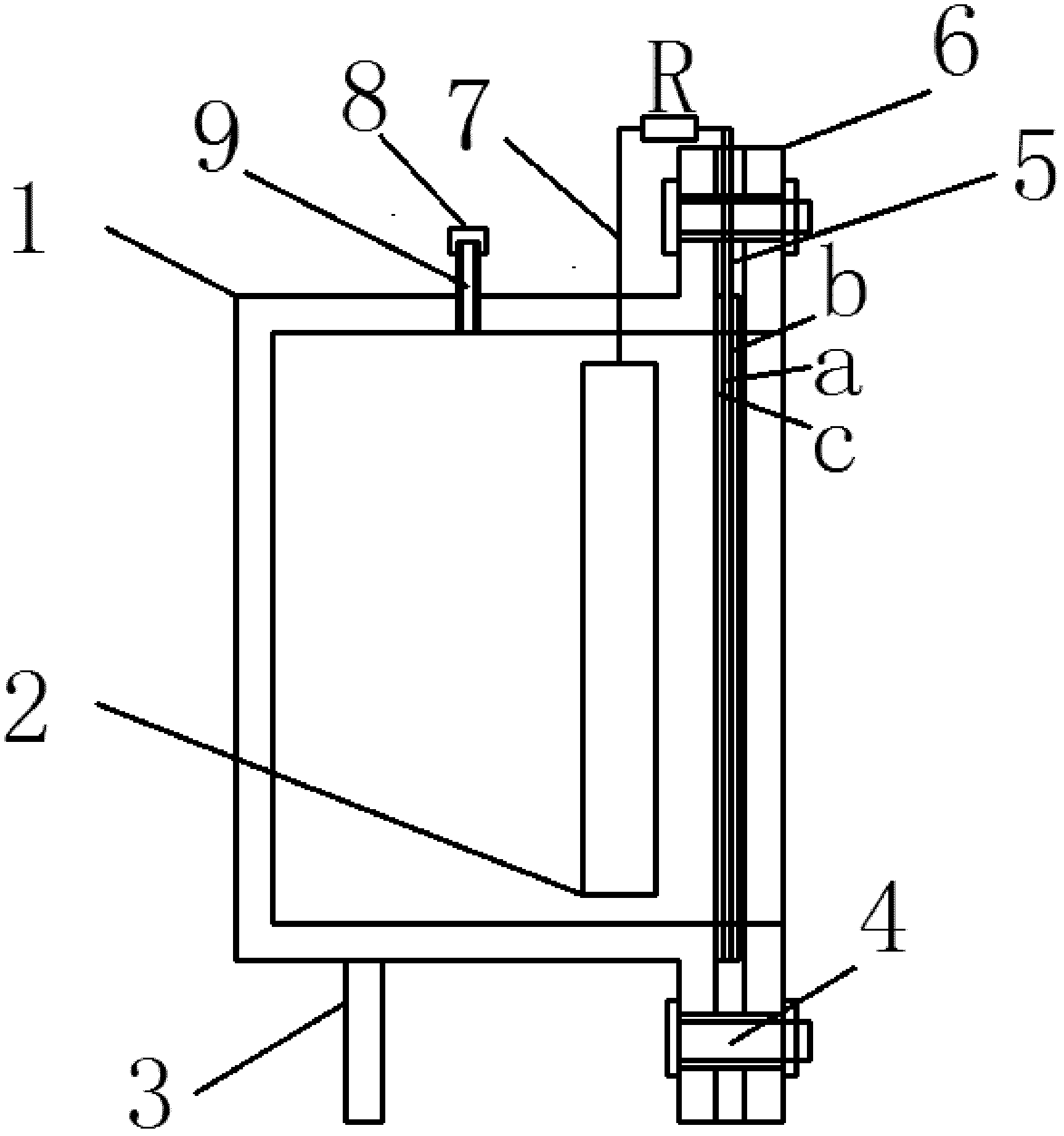

[0030] Such as figure 1 As shown, the cathode is composed of diffusion layer c, stainless steel mesh b and catalytic layer a. Prepare the cathode according to the following steps: (1) Cut a stainless steel mesh with a mesh number of 100, length × width = 5.5 cm × 4.5 cm, and reserve a length of 3 cm for connecting to an external circuit, and use absolute ethanol to sonicate before use 30 minutes. (2) Mix the conductive carbon black and polymethylphenylmethylsilane at a mass ratio of 3:10, spread it evenly on the stainless steel mesh, and dry it at room temperature for half an hour. (3) The synthesis method of the manganese dioxide catalyst supported by carbon nanotubes is as follows. Mix potassium permanganate solution with a concentration of 0.1 mol / L and carbon nanotubes with a length of 5 to 15 um at 100 mL: 400 mg, adjust The pH value of the solution is equal to 1.0, the temperature is controlled at 60° C. and heated for 7 hours, then filtered under reduced pressure...

Embodiment 2

[0036]Example 2 Prepare the cathode according to the following steps: (1) Cut a stainless steel mesh with a mesh number of 150, length × width = 5.5 cm × 4.5 cm, and reserve a length of 3 cm for connecting an external circuit. Hydro-ethanol sonication for 30 minutes. (2) Mix conductive carbon black and polymethylphenylmethylsilane at a mass ratio of 3: 11, spread evenly on the stainless steel mesh, and dry at room temperature for half an hour. (3) The synthesis method of the manganese dioxide catalyst supported by carbon nanotubes is as follows, the potassium permanganate solution with a concentration of 0.075 moL / L is mixed with carbon nanotubes with a length of 5-15 um according to 100 mL: 550 mg , adjust the pH value of the solution to be equal to 1.5, control the temperature at 65°C and heat for 7 hours, then filter under reduced pressure, wash, and then dry the washed filter cake at a temperature of 110°C to prepare a carbon nanotube-loaded manganese dioxide catalyst . ...

Embodiment 3

[0039] Example 2 Prepare the cathode according to the following steps: (1) Cut a stainless steel mesh with a mesh number of 200, length × width = 5.5 cm × 4.5 cm, and reserve a length of 3 cm for connecting to an external circuit. Hydro-ethanol sonication for 30 minutes. (2) Mix conductive carbon black and polymethylphenylmethylsilane at a mass ratio of 3:13, spread evenly on the stainless steel mesh, and dry at room temperature for half an hour. (3) The synthesis method of the manganese dioxide catalyst supported by carbon nanotubes is as follows, the potassium permanganate solution with a concentration of 0.045 moL / L is mixed with carbon nanotubes with a length of 5-15 um according to 100 mL: 700 mg , adjust the pH value of the solution to be equal to 1.5, control the temperature at 70°C and heat for 5 hours, then filter under reduced pressure, wash, and then dry the washed filter cake at a temperature of 120°C to prepare a carbon nanotube-loaded manganese dioxide catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com