Non-aqueous electrolyte of lithium ion battery and battery manufactured by using same

A non-aqueous electrolyte, lithium-ion battery technology, used in secondary batteries, circuits, electrical components, etc., can solve the problems of unstable film formation, capacity attenuation, etc., to improve high-temperature storage performance, improve wettability, and improve The effect of safety features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] One. The preparation method of embodiment electrolyte

[0034] in an argon-filled glove box (H 2 O<10ppm), high flash point, high boiling point cyclic carbonate, cyclic carboxylate and cyclic sulfite organic solvent, linear fluoroether, lithium salt, film-forming additive and fluorocarbon surfactant The electrolyte mass ratios listed in each embodiment and comparative example in Table 1 were prepared. The above-mentioned raw materials are added in sequence and fully stirred evenly to obtain the lithium-ion battery electrolyte of the present invention, which is used for flammability test and battery performance test.

[0035] Two. The manufacture method of embodiment lithium-ion battery

[0036] The non-aqueous electrolyte secondary battery of the present invention is composed of the above-mentioned non-aqueous electrolyte, a negative electrode and a positive electrode.

[0037] The active material constituting the positive electrode can be LiCoO 2 , LiMn 2 o 4 , L...

Embodiment 1

[0075] The production of the positive electrode: the LiCoO 2 , the conductive agent acetylene black and polyvinylidene fluoride are mixed in a weight ratio of 8:1:1, fully dispersed in N-methylpyrrolidone as a solvent to form a paste, and the paste mixture is uniformly coated on a 20 μm as the positive electrode collector Both sides of the strip-shaped aluminum foil of the electric body. The length of the positive electrode sheet is 413 mm, and then dried to obtain a strip-shaped positive electrode sheet with a thickness of 100 um under a pressure of 0.5-2 MPa.

[0076]Preparation of negative electrode: mix natural graphite and polyvinylidene fluoride at a weight ratio of 9:1, disperse the mixture in deionized water solvent to form a paste, and evenly coat the paste mixture on 15um to serve as the negative electrode collector Both sides of the ribbon copper foil. The length of the negative electrode sheet is 420 mm, and then dried to obtain a strip-shaped negative electrode ...

Embodiment 2

[0083] The same as the process of Example 1, the difference is that the electrolyte ratio is:

[0084] γBL:S 1 :PS=50:30:20, 1.4M LiBF 4 , VC: 1%.

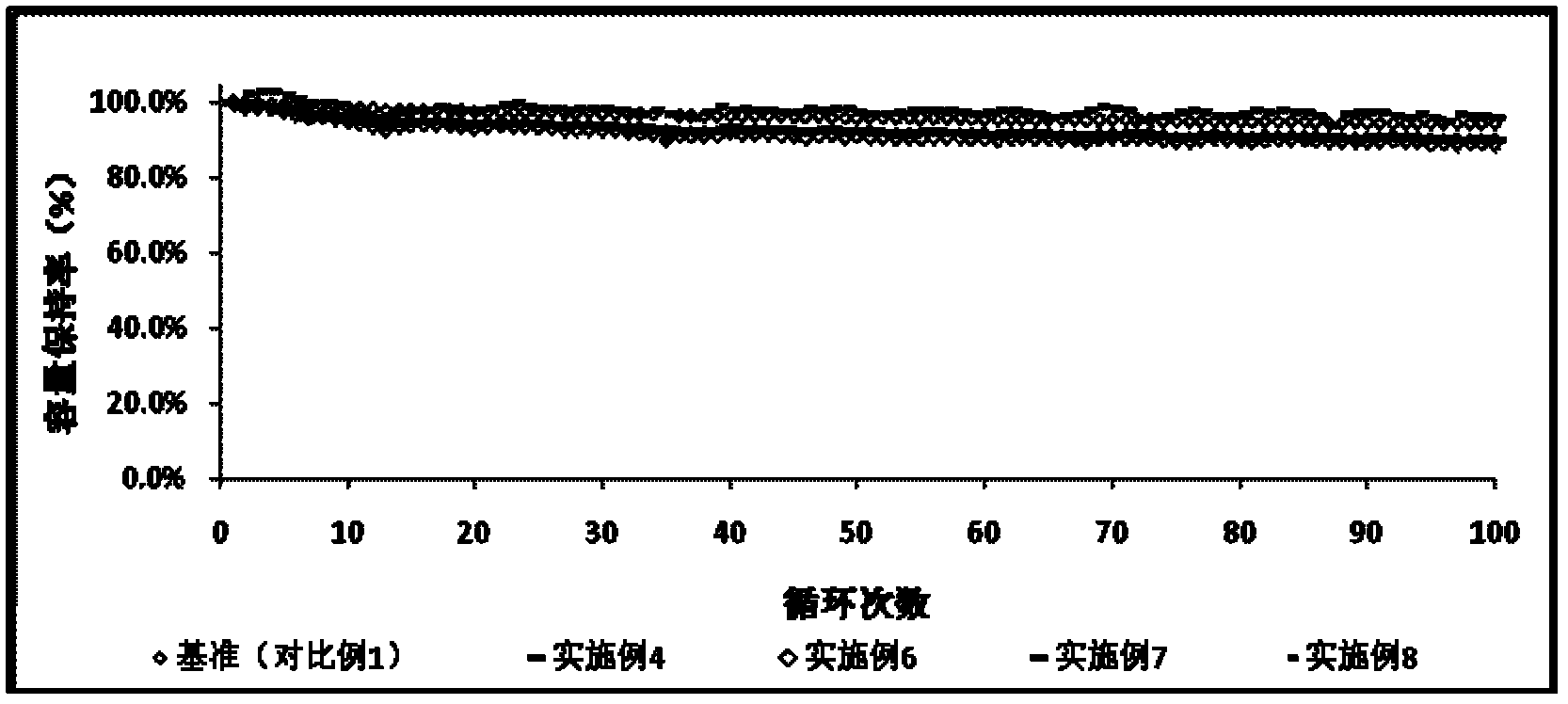

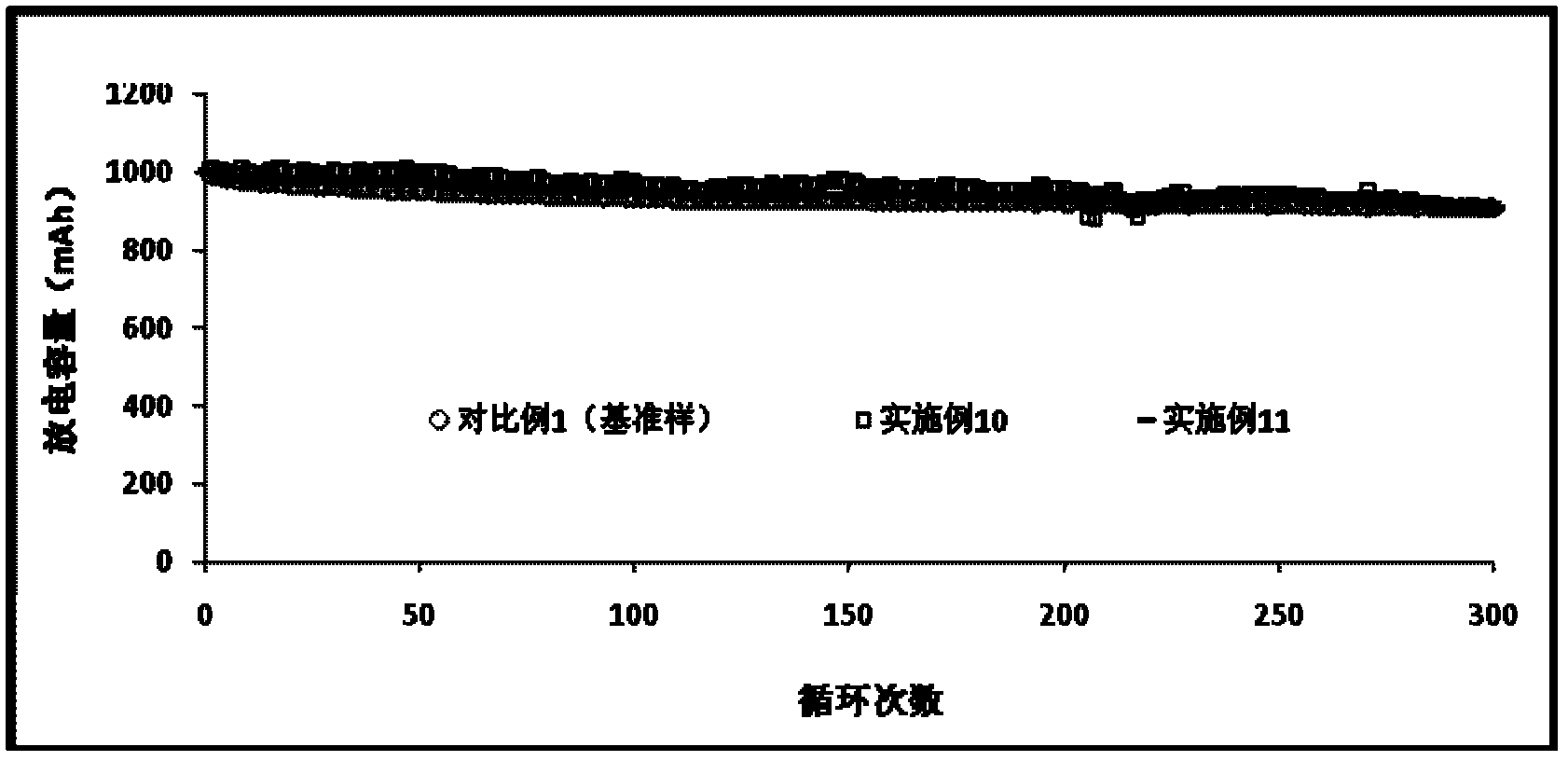

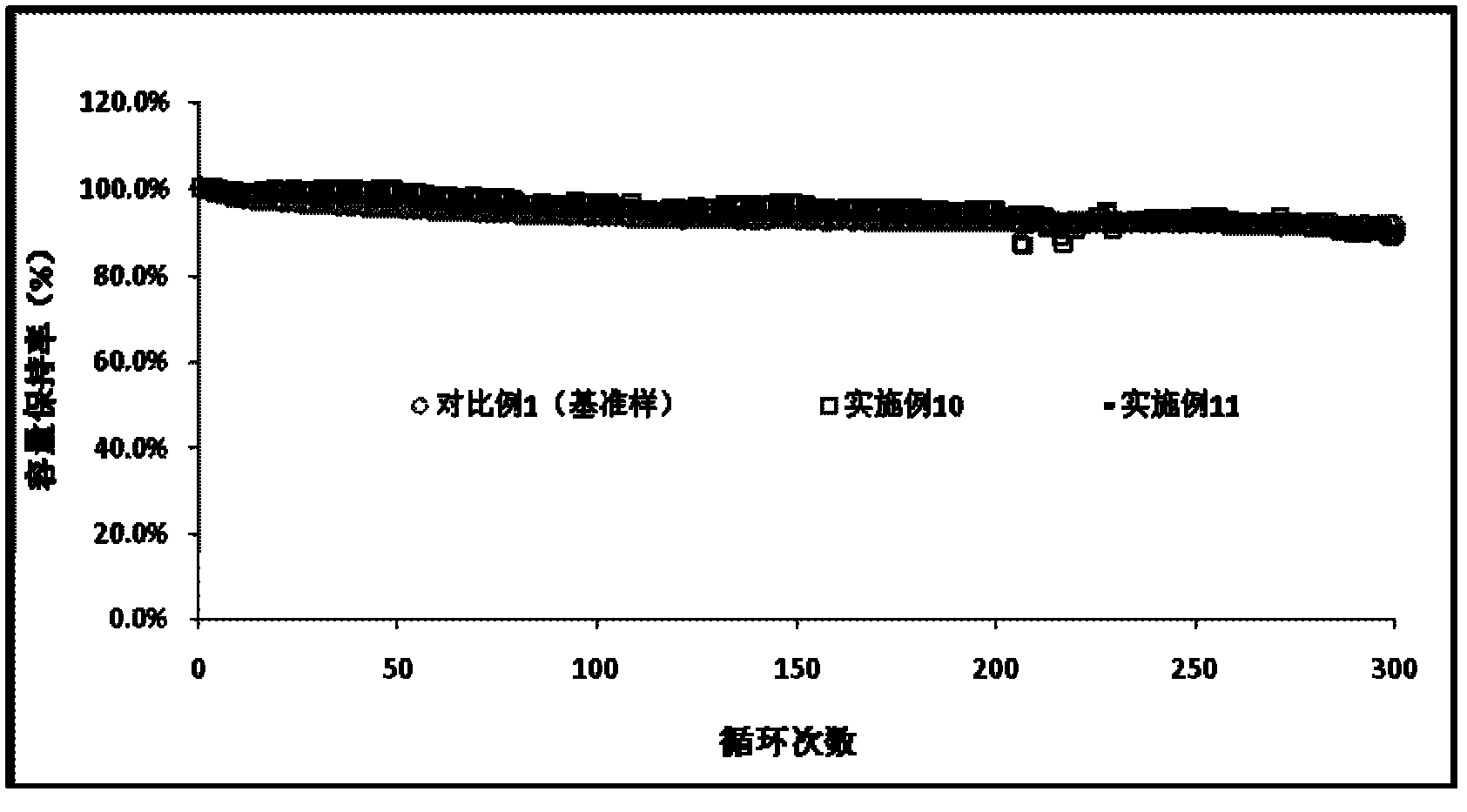

[0085] The obtained electrolyte was used for flammability test and battery performance test. The test results of flammability performance, initial performance and 100 cycle capacity retention at room temperature; the capacity retention rate, capacity recovery rate and thickness expansion rate after high temperature storage are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com