Method for continuously reducing, rolling and compositing stainless steel/plain steel composite plate and device thereof

A stainless steel plate and rolling composite technology, applied in the direction of metal rolling, metal rolling, rolls, etc., can solve the problems of large surface area of metal strips, low interface bonding strength, large crimping force, etc., and achieve low equipment investment and reduction time Short, low heat load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

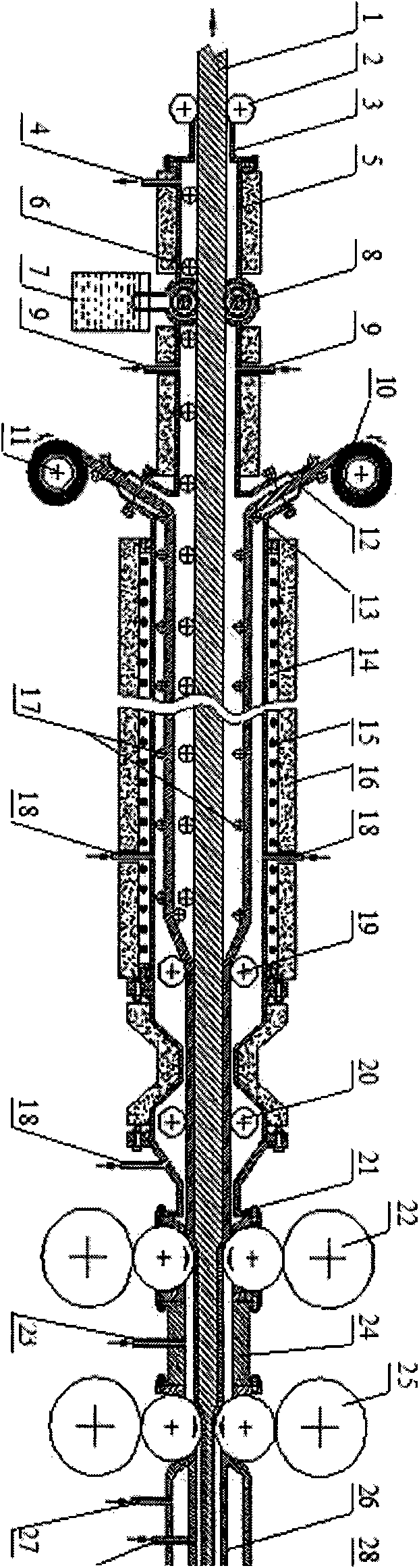

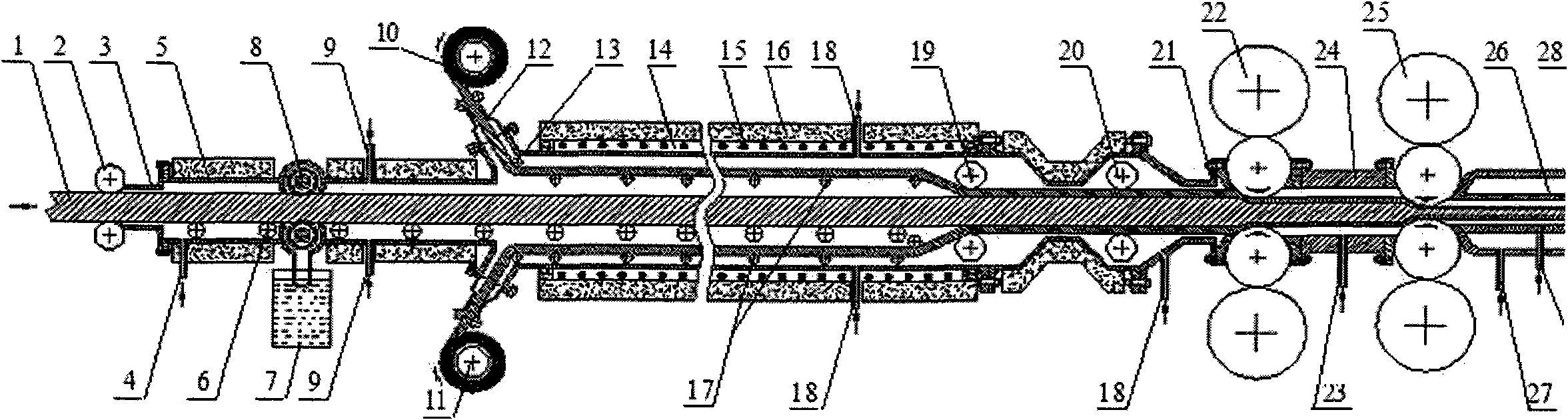

[0031] The 16Mn low-alloy structural steel slab 1 with a thickness of 100mm, heated to 1180°C by an ordinary flame furnace, and dephosphorized by high-pressure water is pinched by the slab entrance guide roller 2, and enters the front heat preservation reduction furnace 5 through the slab entrance sealing guide nozzle 3 Inside, it runs smoothly on the billet running roller table 6; the wire brush 8 rotates at high speed and scrapes the surface of the slab, and the shed iron oxide scale falls into the sealed water tank 7 below; the reducing gas produced by ammonia decomposition is 100% h 2 Through the reducing gas inlet pipe 9, it enters the heat preservation reduction furnace 5 in the front section, and is sprayed onto the surface of the billet to accelerate the reduction of the oxide scale on the surface of the billet; the SUS304L stainless steel strip 10 with a thickness of 12 mm after pickling to remove the scale passes through two stainless steel plates up and down. The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com