Spherical integral macroporous alumina and preparation method thereof

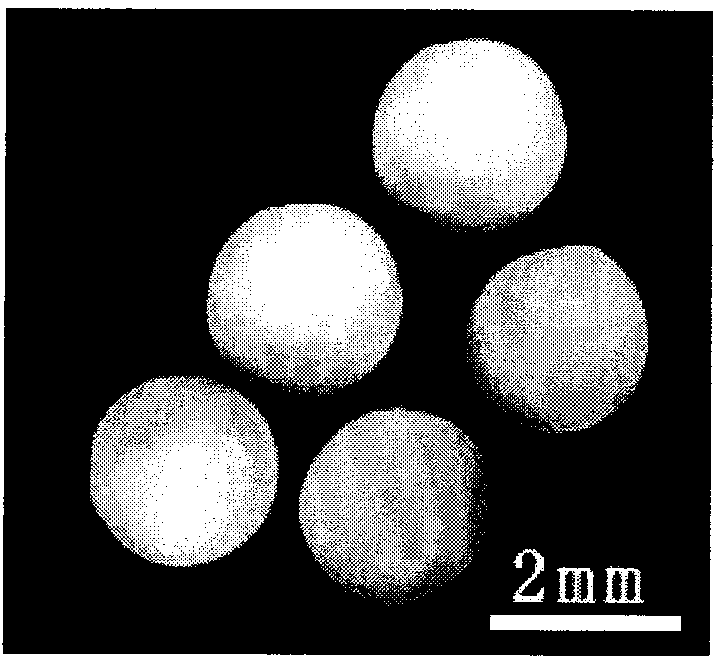

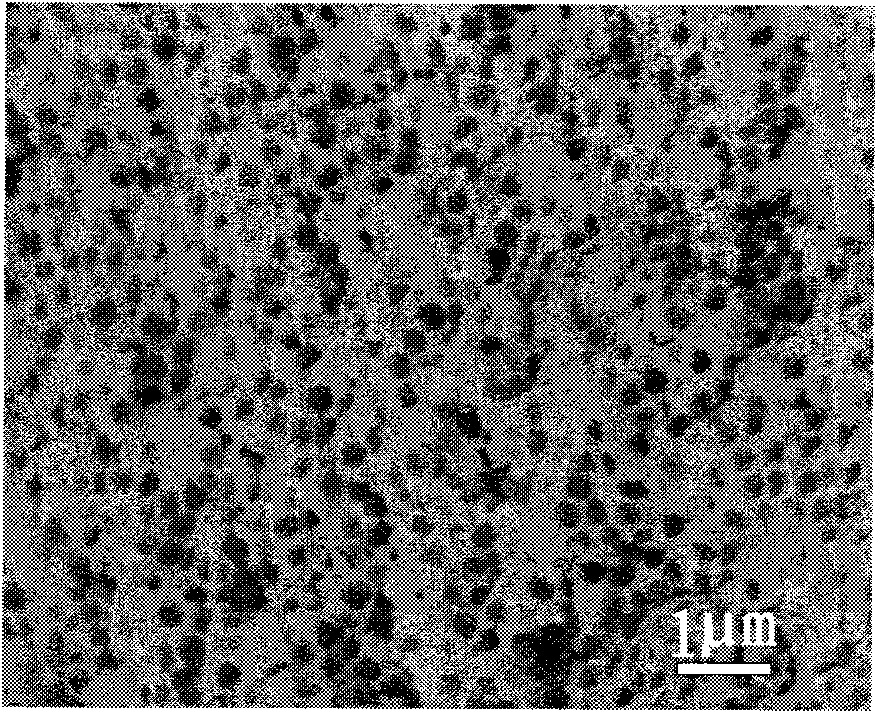

A technology of macroporous alumina and spherical alumina, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of unsuitability for mass production, fragile products, low preparation efficiency, etc., and achieve easy mass operation and molding. Simple and easy to implement, the effect of large pore size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Synthesis of Monodisperse Polymer Microspheres. Get an appropriate amount of twice-distilled water and heat it to boil for 10 minutes to reduce the dissolved oxygen content in the water. After natural cooling of distilled water, 135 mL was added to a three-necked flask, and then the flask was placed in a water bath and heated to 75°C. Add 0.1348 g NaHCO 3 , start the stirrer, and start feeding N at the same time 2 , stabilized for 10 minutes to make NaHCO 3 Fully dissolve. Then add 0.0666 g of emulsifier and stabilize for 10 minutes, then add 30.7 mL of styrene monomer (St) and stabilize for 30 minutes. Finally, 0.1368 grams of initiator potassium persulfate (KPS) was added. The reaction system was kept at a constant temperature of 75° C., and the stirrer rotated at 300 rpm. After reacting for 20 hours, it was observed that there were basically no oil droplets on the wall of the three-necked flask. It can be considered that the conversion of styrene monomer had be...

Embodiment 2-4

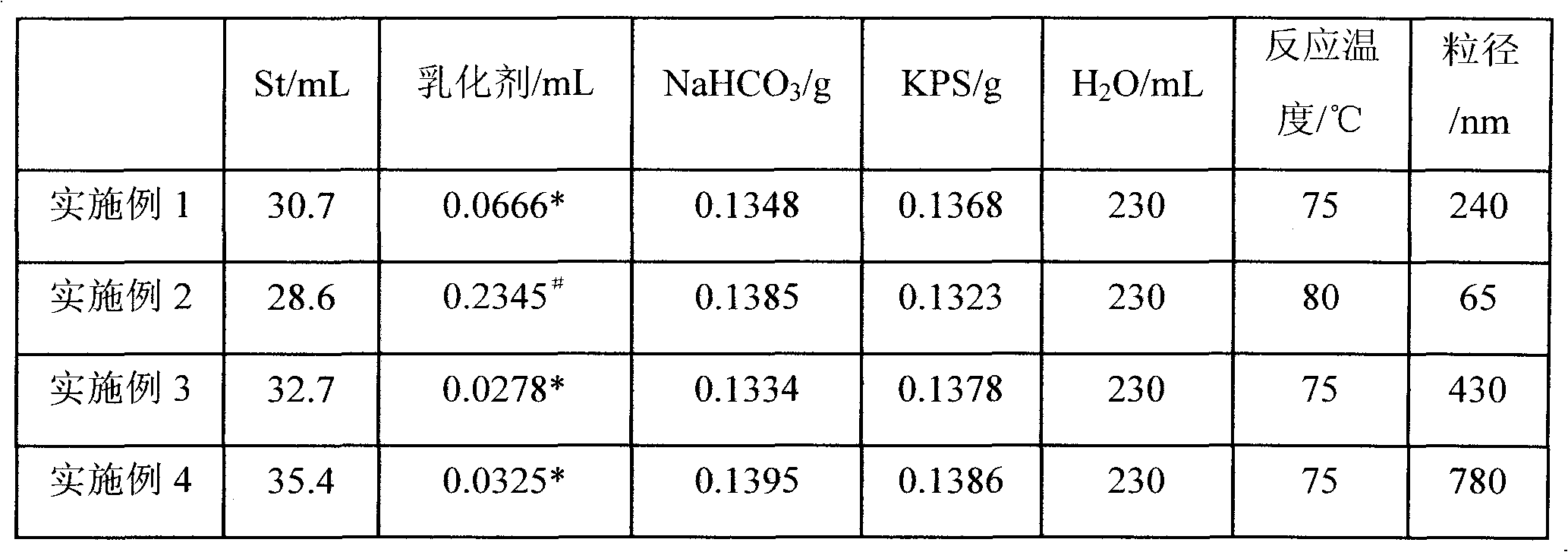

[0029] According to the method of Example 1, polystyrene emulsion particles with different particle sizes can be synthesized by changing the dosage of each reagent. The specific test data are shown in Table 1.

[0030] Table 1 Synthesis of polystyrene microspheres by styrene emulsion polymerization

[0031]

[0032] #The emulsifier used is sodium lauryl sulfate; *The emulsifier used is sodium p-styrenesulfonate.

Embodiment 5

[0034] Alumina sol was prepared from aluminum nitrate. Make 7.5 grams of aluminum nitrate into a 0.5 mol / L solution, slowly add 1 mol / L ammonia water dropwise while stirring at room temperature until the pH is approximately equal to 8, and a white precipitate is obtained. After repeated washing of the precipitate with distilled water, the precipitate is washed with Disperse with 25ml of distilled water, then add 5ml of HNO with a concentration of 1.0mol / L 3The solution was peptized, and then sealed and aged at 85°C for 12 hours to obtain a transparent alumina sol, numbered ASol1.

[0035] Alumina sol was prepared from pseudoboehmite as raw material. 15 grams of pseudo-boehmite and 200 grams of distilled water were mixed and beaten, and then peptized with 30 ml of nitric acid with a concentration of 1.0 mol / L to obtain a stable and transparent alumina sol, coded ASol2.

[0036] Alumina sol was prepared from aluminum isopropoxide. Put aluminum isopropoxide / water in water at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com