Brittleness inhibition method of chemical function improved wood

A chemical modification, wood technology, applied in the direction of impregnated wood, wood impregnation, wood processing utensils, etc., can solve the problems of wood bending strength, tensile strength and impact strength reduction, toughness decline, melamine becomes brittle, etc., to reach the size Effects of improved stability, improved impact strength, and increased overall density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The technical solutions of the present invention are not limited to the specific embodiments exemplified below, but also include specific combinations among the specific embodiments.

[0019] Basic implementation method: use polyhydric alcohol compounds as toughening aids, natural organic acids as catalysts, and low-molecular-weight methylol resins as modifiers to compound as functional improvement reagents to treat wood or wood substrates, inhibiting chemical modification and causing wood brittleness. The basic method is as follows:

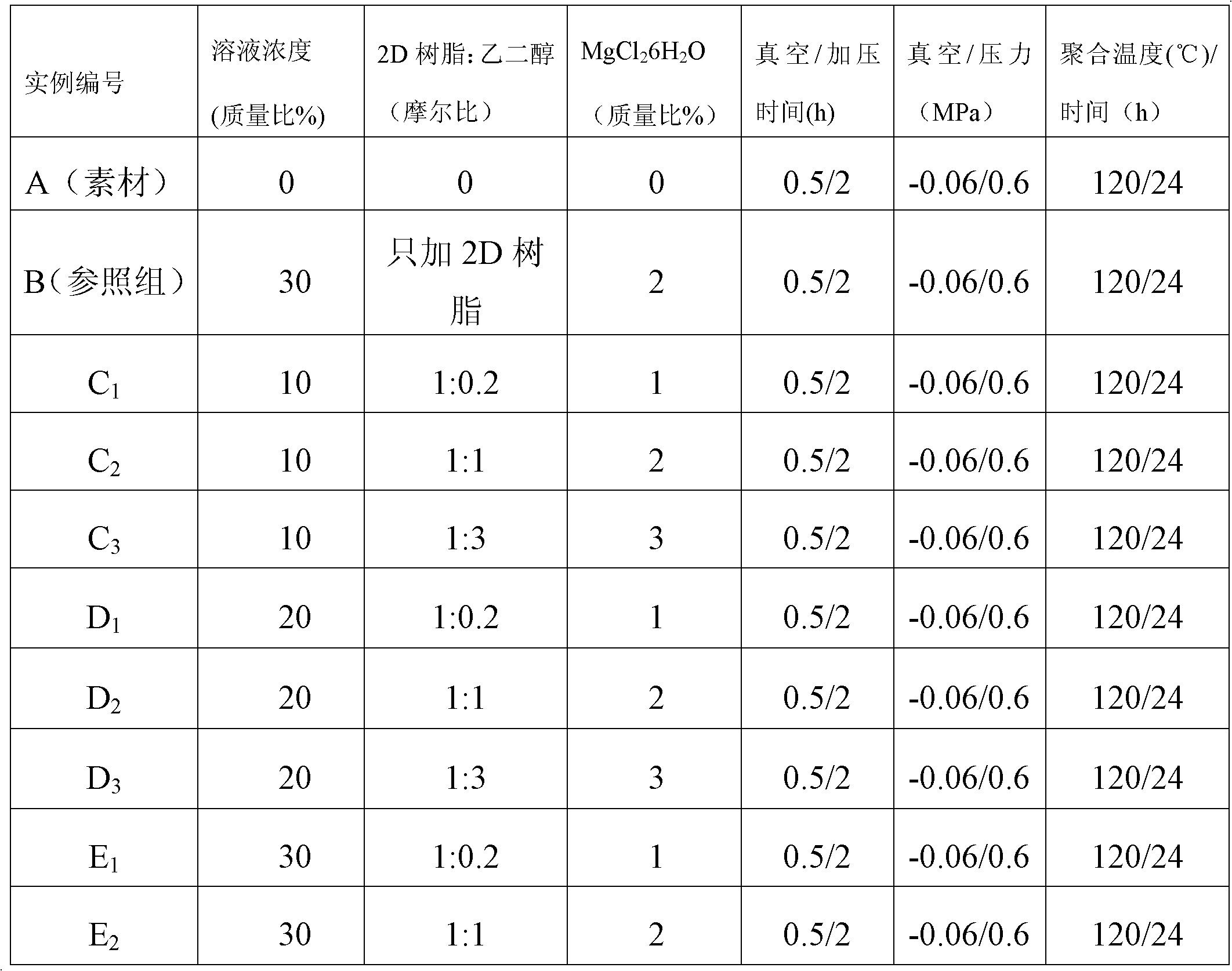

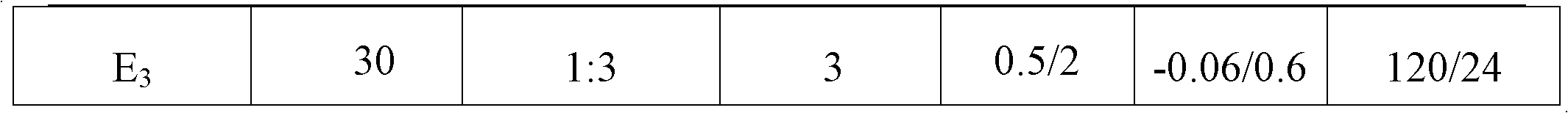

[0020]One, the formula of modifying agent: choose a polyhydric alcohol compound at least, and select a kind of methylol compound at least, the mol ratio of two kinds of compounds (polyhydric alcohol: methylol compound) is 0.2~3: 1, Add deionized water to make a solution with a mass fraction of 5-50%, and add a certain amount of functional catalyst, such as citric acid, magnesium chloride or zinc chloride, according to 0.1-5% of the soluti...

specific Embodiment approach 1

[0023] Specific implementation mode one: the selection of modified materials. The modification objects selected in this embodiment can be: wood of various quality grades and various wood substrates such as medium density fiberboard, particle board or plywood.

specific Embodiment approach 2

[0024] Specific embodiment two: the selection of polyhydric alcohol compound. According to the first part of the basic implementation method, the difference of this embodiment is that the selection of polyhydric alcohols in this embodiment, the polyhydric alcohol compounds that can be further selected are ethylene glycol, polyethylene glycol, 1,2-propanediol, 1 , 3-propanediol, butanediol, 1,2-pentanediol, 1,2-hexanediol, glycerin, sorbitol, 1,4-butanediol, 1,6-hexanediol, 1,12- One or more combinations of dodecanol, diethylene glycol, triethylene glycol, tetraethylene glycol, dipropylene glycol, tripropylene glycol, tetrapropylene glycol, diglycerol, and triglycerol. The polyhydric alcohol used has 2-18 carbon atoms, is soluble in water, and has a boiling point above 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com