Surface particle reinforced composite material layer of iron cast member and preparation method thereof

A technology for reinforcing composite materials and castings. It is applied to the surface particle reinforced composite material layer of iron castings and its preparation field. It can solve the problems of uneven surface of composite materials, poor penetration of molten metal, internal pores and slag inclusions, etc., and achieve high The effect of combining strength, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

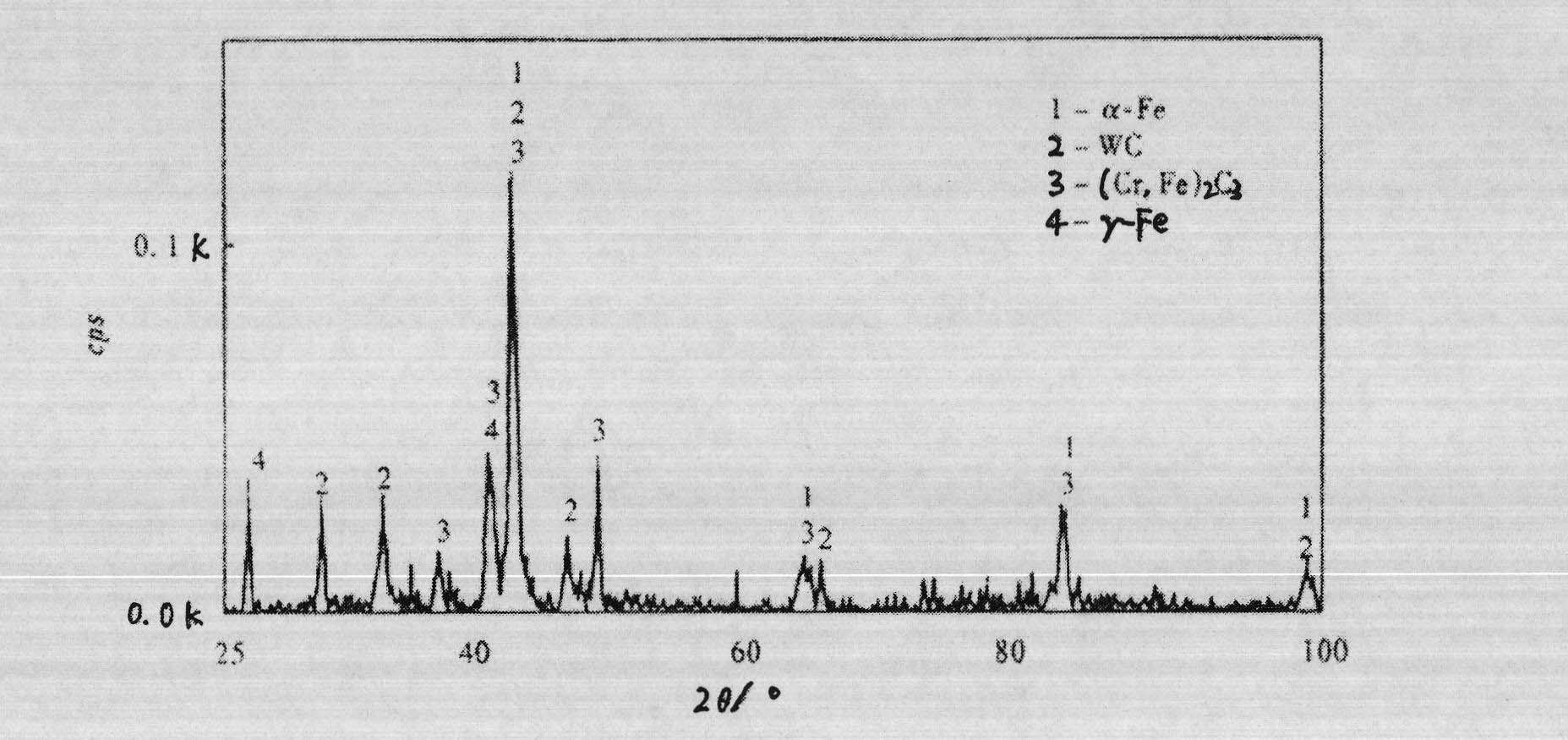

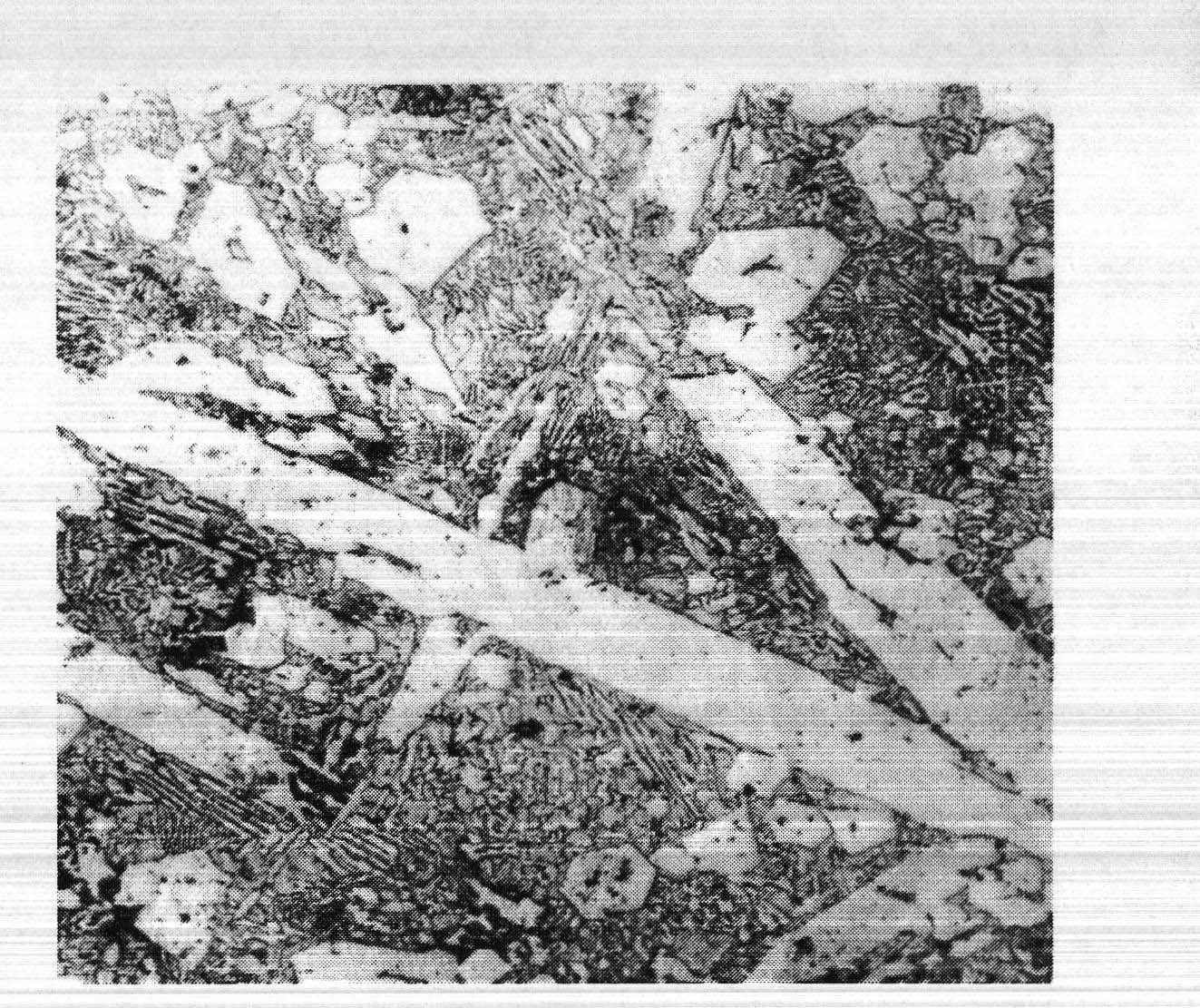

[0035]Embodiment 1: the alloy powder composition and content are: 19.2 parts of tungsten carbide, 47.5 parts of high-carbon ferrochromium, 24.7 parts of gray cast iron powder, 3 parts of calcium-silicon alloy, 1 part of sodium fluoride, rare earth magnesium alloy (more magnesium-containing nodulizer) 2 parts, borax 2.6 parts; alloy powder particle size: 0.2mm; pouring temperature is 1370°C, lambda value is 14. During preparation, mix the alloy powder evenly with polyvinyl alcohol (PVA) colloid, adjust it into a paste, coat it on the bottom surface of the casting mold molded with water glass surface sand, dry it with a blowtorch for 5-10 minutes, close the box, and then put the warp into the sky The molten iron smelted in the furnace is poured by top injection and cooled naturally. The layer phase composition of the composite material obtained in this way is mainly WC, (Cr, Fe) 7 C 3 , eutectic austenite and martensite, WC in the as-cast structure is white square, (Cr, Fe) 7...

Embodiment 2

[0036] Embodiment 2: the alloy powder composition and content are: 20 parts of tungsten carbide, 50 parts of high-carbon ferrochromium, 25 parts of gray cast iron powder, 1 part of calcium-silicon alloy, 1 part of sodium fluoride, rare earth magnesium alloy (more magnesium-containing Nodulizer) 1 part, borax 2 parts; alloy powder particle size: 0.3mm; pouring temperature 1370°C, lambda value 14. During preparation, mix the alloy powder evenly with polyvinyl alcohol (PVA) colloid, adjust it into a paste, and make a paste alloy with a size of 30×30×3mm, and place it in a rectangular parallelepiped with a size of 30×30×170mm. The middle part of the mold is then poured with molten iron to form a sample in which the middle part is the cast iron matrix and the two ends are the cast iron matrix. Then process it into a round short sample in the GB228-76 standard, and do a tensile test on a WE-10 universal tensile testing machine. Due to the addition of alloying elements, the bonding ...

Embodiment 3

[0037] Embodiment 3: the composition and content of alloy powder are: 20 parts of tungsten carbide, 47 parts of high-carbon ferrochromium, 25 parts of gray cast iron powder, 2 parts of calcium-silicon alloy, 1 part of sodium fluoride, rare earth magnesium alloy (containing more magnesium nodulizer) 3 parts, borax 2 parts; alloy powder particle size: 0.2mm; pouring temperature is 1370°C, lambda value is 14. During preparation, adopt the preparation method of embodiment 2, and do compression test on WE-10 type universal tensile testing machine. The addition of alloying elements can increase the shear strength of the infiltrated layer and the matrix, causing the specimen to fracture on the gray cast iron matrix, with a compressive strength of 592 MPa, as shown in Figure 4(c), black is the composite material layer 2 , the others are matrix 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com