Method and device for preparing polycrystalline silicon solar cell texture

A solar cell and polysilicon technology, applied in circuits, electrical components, manufacturing tools, etc., can solve problems affecting processing quality and use effects, achieve high-quality and efficient suede processing, improve suede preparation efficiency, and high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

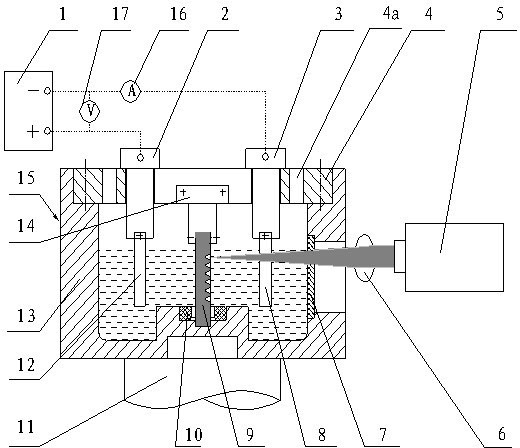

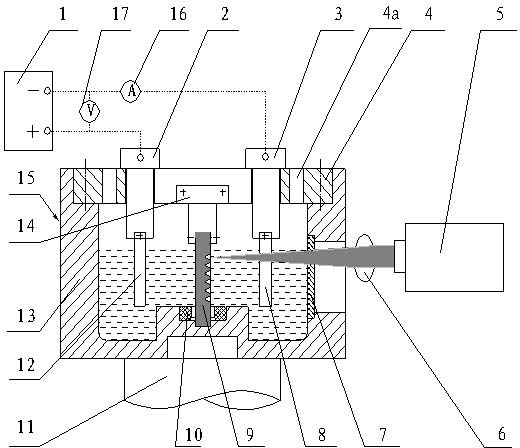

[0031] The suede preparation of the polycrystalline silicon chip of the present embodiment carries out the preparatory work of following steps:

[0032] 1) Device assembly: an excimer laser with a wavelength of 193nm is used, the laser beam emitted is a pulsed laser, the beam transverse mode is a low-order mode, and the electrolysis voltage provided by the power supply is 5~8V; the polysilicon wafer with a thickness of 300 microns Connect and install to the corresponding part of the electrolyzer base 13.

[0033] 2) Inject electrolyte: slowly inject KOH electrolyte into the two chambers through the two liquid inlet vent holes on the cover plate 4 of the electrolytic cell. The pH value of the electrolyte is 9, the concentration is 20%, and the liquid level is slightly higher than The workpiece area to be processed is lower than the lower ends of the workpiece mounting fixture 14, the anode socket 2, and the cathode socket 3;

[0034] 3) Optical path detection: confirm that the...

Embodiment 2

[0041] The suede preparation of the polycrystalline silicon chip of the present embodiment carries out the preparatory work of following steps:

[0042] 1) Device assembly: a semiconductor laser with a wavelength of 532nm is used, the laser beam emitted is a continuous laser, the beam transverse mode is a low-order mode, and the electrolysis voltage provided by the power supply is 2~5V; the polysilicon wafer with a thickness of 250 microns is connected Install to the corresponding part of the electrolyzer base 13.

[0043] 2) Inject electrolyte: slowly inject KOH electrolyte into the two chambers respectively through the two liquid inlet vent holes of the electrolytic cell cover plate 4. The pH value of the electrolyte is 9.5, the concentration is 25%, and the liquid level is slightly higher than The workpiece area to be processed is lower than the lower ends of the workpiece mounting fixture 14, the anode socket 2, and the cathode socket 3;

[0044] 3) Optical path detection...

Embodiment 3

[0051] The suede preparation of the polycrystalline silicon chip of the present embodiment carries out the preparatory work of following steps:

[0052] 1) Device assembly: use a Nd:YAG laser with a wavelength of 1064nm, the transverse mode of the beam is a low-order mode, and the electrolysis voltage provided by the power supply is 5~8V; connect and install a polysilicon wafer with a thickness of 300 microns to the base of the electrolytic cell 13 corresponding parts.

[0053] 2) Inject electrolyte: slowly inject NaOH electrolyte into the two chambers through the two liquid inlet vent holes of the electrolytic cell cover plate 4. The pH value of the electrolyte is 10, the concentration is 30%, and the liquid level is slightly higher than The workpiece area to be processed is lower than the lower ends of the workpiece mounting fixture 14, the anode socket 2, and the cathode socket 3;

[0054] 3) Optical path detection: confirm that the optical path is smooth, the focusing len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com