Preparation method of nemadectin

A technology of nemoctine and macroporous resin, which is applied in the field of preparation of high-purity nemoctine and antibiotics, and can solve the problems of increased cost of nemoctine extraction, low purity of nemoctine, and a large amount of filtered waste water. Achieve the effects of low cost, significant economic benefits and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Fermentation production process of nimoctin:

[0017] The components and contents of the fermentation medium are: glucose 4.0%

[0018] Maltose 7.0%

[0019] Soya flour 2.5%

[0020] Yeast extract powder 0.5%

[0023] Adjust the pH of the medium to 7.0, then sterilize at 121°C for 30 minutes, and set aside.

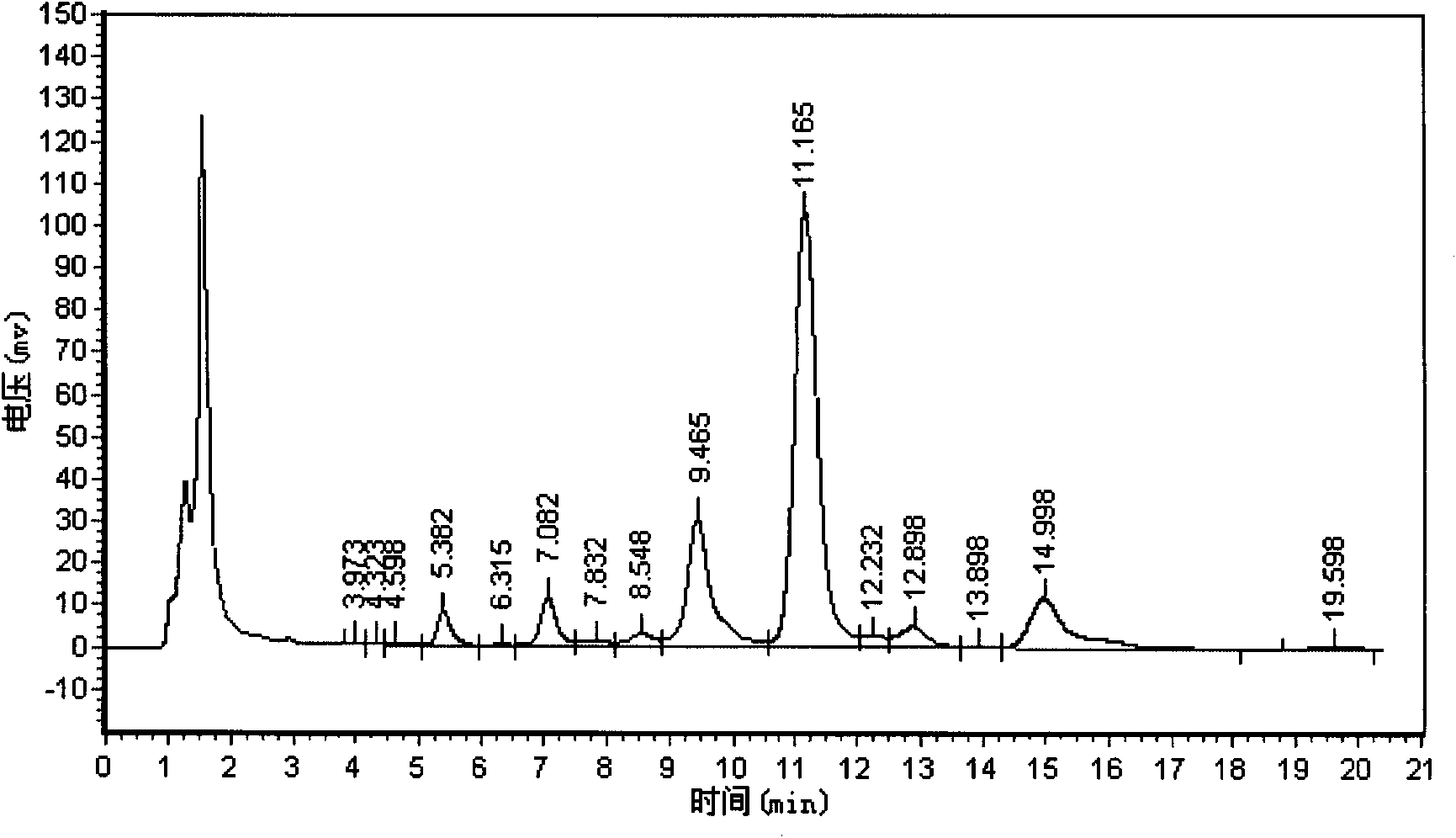

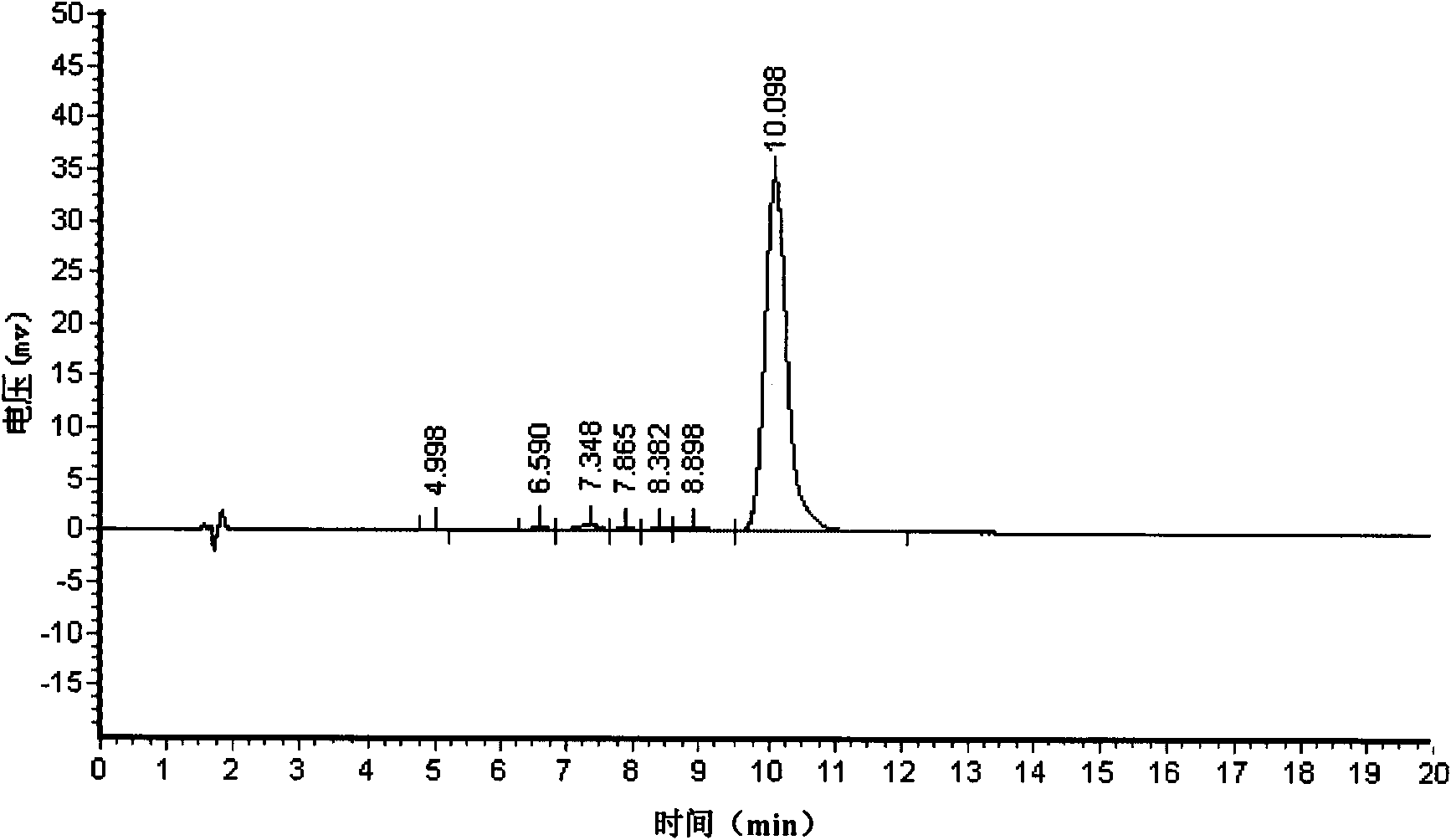

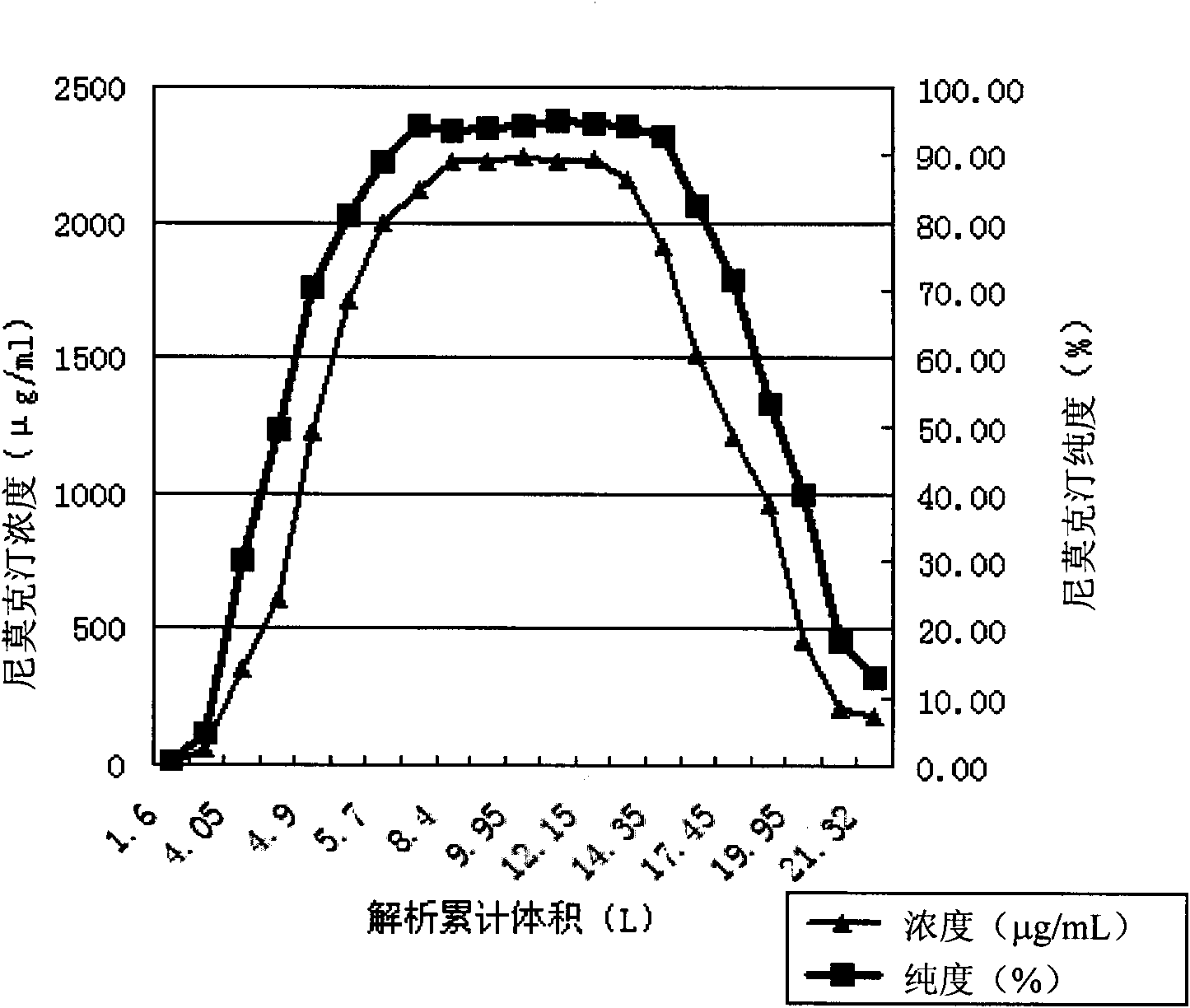

[0024] Add 1 L of the prepared Streptomyces coustrigeus seed solution (Note: the bacterial concentration of the seed solution is 18-24%, which is the volume percentage of the bacterial sediment measured after centrifugation) into 30 L of the prepared fermentation medium , cultivated at 28°C for 214h. Then use HPLC to detect the purity of nimoctine in the fermented liquid. The specific method is: take 5 ml of fermented liquid and add 10 ml of meth...

Embodiment 2

[0030] 1. Fermentation production process of nimoctin:

[0031] The components and contents of the fermentation medium are: soluble starch 2%

[0032] Lactose 8%

[0033] Cottonseed meal 3%

[0034] Yeast autodissolving powder 1%

[0037] Adjust the pH of the medium to 7.0, then sterilize at 121°C for 30 minutes, and set aside.

[0038] Put 1 L of the prepared Streptomyces coustrigeus seed solution (Note: the bacterial concentration of the seed solution is 18-24%, V / V) into 30 L of the prepared fermentation medium, and culture at 28° C. for 220 h. Using the same method as in Example 1, the fermentation unit of nimoctine in the fermentation broth determined by HPLC was 1.78 g / L, and the purity was greater than 53%.

[0039] 2. Direct spray drying process:

[0040...

Embodiment 3

[0044] 1. Fermentation production process of nimoctin:

[0045] The components and contents of the fermentation medium are: soluble starch 1%

[0046] Lactose 3%

[0047] Cottonseed meal 3%

[0048] Yeast autodissolving powder 1%

[0051] Adjust the pH of the medium to 7.0, then sterilize at 121°C for 30 minutes, and set aside.

[0052] Put 1 L of the prepared Streptomyces coustrigeus seed solution (Note: the bacterial concentration of the seed solution is 18-24%, V / V) into 30 L of the prepared fermentation medium, and culture at 28° C. for 220 h. Using the same method as in Example 1, the fermentation unit of nimoctine in the fermentation broth determined by HPLC was 1.66 g / L, and the purity was greater than 50%.

[0053] 2. Direct spray drying process and nem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com