Three-layer core-shell-structure inorganic nanoparticle/silicon dioxide/high polymer composite microspheres and preparation method thereof

A technology of inorganic nanoparticles and silicon dioxide, applied in the field of composite materials, to achieve the effects of shortened experiment time, uniform particle size, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 2mg of CdSeTe quantum dots with an emission wavelength of 517nm, dissolve the quantum dots in 0.5ml of chloroform, add 10mg of PVP as a stabilizer, and disperse uniformly by ultrasonic;

[0033] Step 2, adding the reactant of step 1 into 10ml of ethanol, stirring until the system is uniform;

[0034] Step 3: Add 30 μl tetraethyl orthosilicate (TEOS) and 15 μl ammonia water to the reaction system in step 2, and react for 12 hours at a stirring speed of 3000 r / min.

[0035] Step 4: Add 30 μl of silane coupling agent (MPS) to the reaction system in Step 3, and react for 6 hours.

[0036] Step 5: Add 15 μl EGDMA, 45 μL MAA and 200 μL AIBN (1 g / mL) to the reaction system in step 4, heat the system to 90 ° C, and stop the reaction when half of the solvent is distilled off; centrifuge and wash to obtain a three-layer core-shell Structural inorganic nanoparticles / silica / polymer composite microspheres.

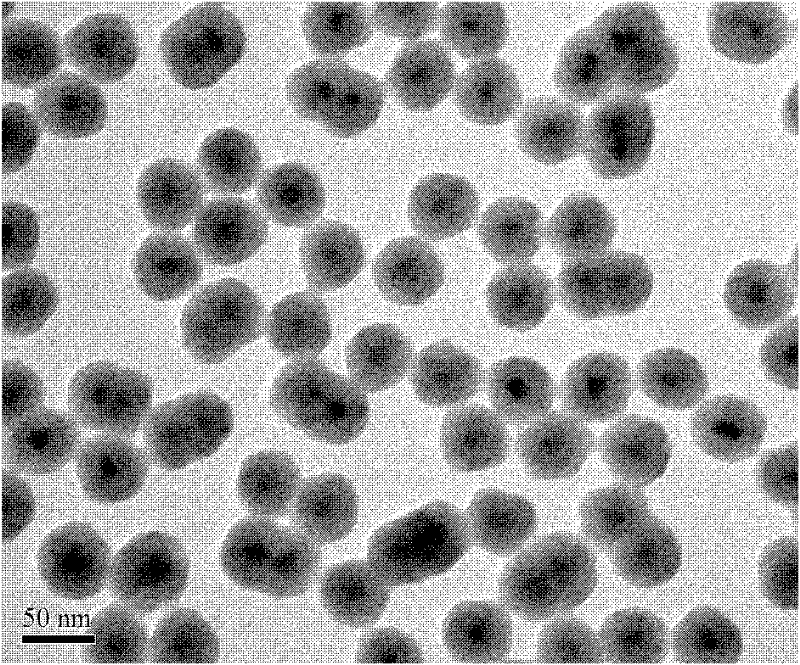

[0037] figure 1 The low-magnification photo of the prepared ...

Embodiment 2

[0039] Step 1: Weigh 1 mg of CdSe / ZnS quantum dots with an emission wavelength of 564 nm, dissolve the quantum dots in 1 ml of chloroform, add 200 mg of PEI as a stabilizer, and disperse uniformly by ultrasonic;

[0040] In step 2, the reactant in step 1 is added to 10ml of acetonitrile, and stirred until the system is uniform;

[0041] Step 3: Add 10 μl tetraethyl orthosilicate (TEOS) and 10 μl ammonia water to the reaction system in step 2, and react for 36 hours at a stirring speed of 3000 r / min.

[0042] Step 4: Add 30 μl of silane coupling agent (MPS) to the reaction system in Step 3, and react for 10 h.

[0043] Step 5: Add 15 μL DVB, 60 μL styrene and 60 μL BPO (1 g / mL) to the reaction system in step 4, heat the system to 95° C., and stop the reaction when half of the solvent is distilled off; after centrifugation and washing, three Inorganic nanoparticles / silica / polymer composite microspheres with layered core-shell structure.

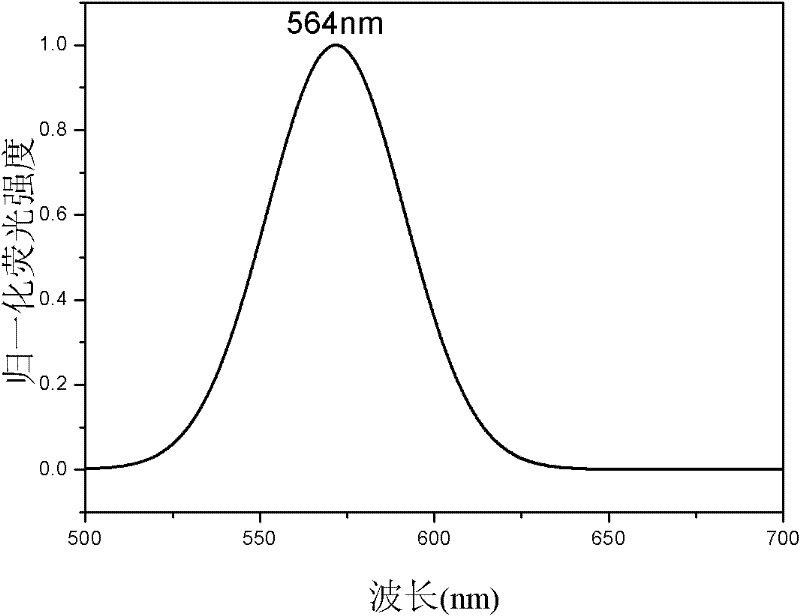

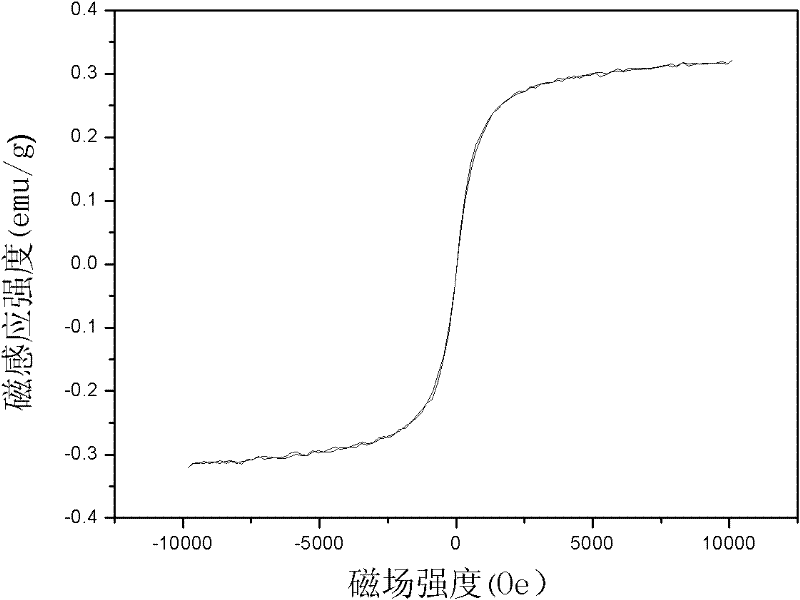

[0044] The prepared composite microsph...

Embodiment 3

[0046] Step 1: Weigh 4mg of CdSe quantum dots with an emission wavelength of 650nm, dissolve the quantum dots in 2ml of cyclohexane, add 200mg of PEO as a stabilizer, and disperse uniformly by ultrasonic;

[0047] Step 2, adding the reactant in step 1 to 5ml of acetonitrile and 5ml of ethanol, stirring until the system is uniform;

[0048] Step 3: Add 60 μl of tetraethyl orthosilicate (TEOS) and 10 μl of ammonia water to the reaction system in Step 2, and react for 48 hours at a stirring speed of 3000 r / min.

[0049] Step 4: Add 20 μl of silane coupling agent (MPS) to the reaction system in Step 3, and react for 12 hours.

[0050] Step 5: Add 20 μl EGDMA, 20 μL MAA, 20 μL styrene, and 200 μL AIBN (1 g / mL) to the reaction system in step 4, heat the system to 90° C., and stop the reaction when half of the solvent is distilled off; after centrifugation and washing, prepare The average particle size is 80nm and the three-layer core-shell structure inorganic nanoparticle / silicon d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com