Solar battery back plate and solar battery

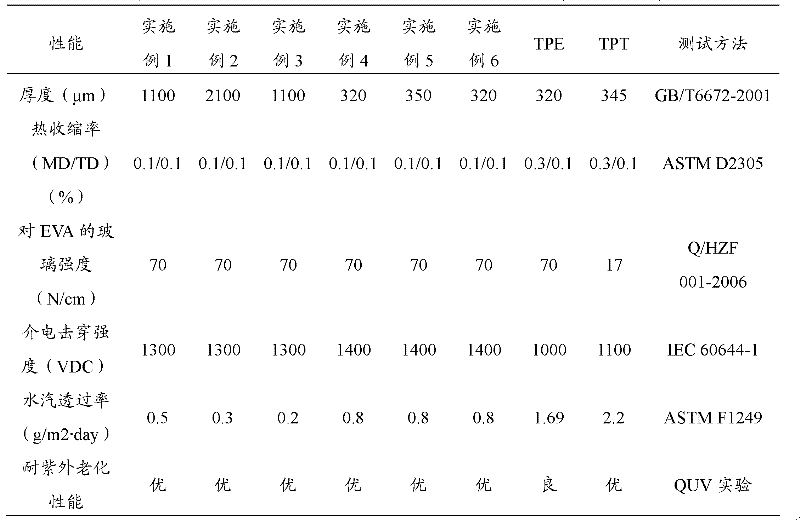

A solar cell and backsheet technology, applied in the field of solar cells, can solve the problems of reduced service life of solar cells, poor UV resistance of the backsheet, lack of hydrolysis stability, etc., and achieve good water vapor barrier performance, good mechanical strength and size The effect of stability, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention has no special limitation on the preparation method of the substrate, and the roll film sheet can be produced by continuous sheet processing, such as using roving, chopped fiber mat, continuous fiber mat, surface mat or fiber cloth, etc. as reinforcing materials. These reinforcing materials are unwound through guide rollers, impregnated with thermosetting resins through a resin impregnation tank filled with resins and additives and other raw materials, and then heated and formed by a crawler-type continuous tablet press to cure the resins. Fiber-reinforced thermosetting resin film sheet; when the reinforcing material is continuous roving, a simple pultrusion process can be used to prepare fiber-reinforced thermosetting sheet.

[0033]The substrate can also be prepared in batch production, such as mixing fibers, resins and additives, using sheet molding compound (Sheet Molding Compound, SMC) or bulk molding compound (Bulk Molding Compound, BMC), by h...

Embodiment 1

[0045] Choose alkali-free glass fiber chopped strand mat (CSM), with a weight of 150g / m 2 , thickness 1.0mm, unwinding by unwinding roller, impregnated by resin impregnation tank equipped with unsaturated polyester resin, said unsaturated polyester resin includes: 100 parts by mass of unsaturated polyester; 35 parts by mass of styrene; 1.5 parts by mass Mass parts methyl ethyl ketone peroxide; 0.5 mass parts mass concentration is 6% cobalt naphthenate solution; During impregnation, the mass ratio that makes alkali-free glass fiber chopped strand mat and unsaturated polyester resin is 65: 35; Impregnating finishes, will obtain The alkali-free glass fiber chopped strand mat impregnated with resin passes through a crawler-type continuous tablet press, and is heated and pressed to form a substrate; the formed substrate is passed through a roller impregnated in liquid acrylate monomer in the lower half, and the impregnation is completed , continue to be conveyed by rollers, and the...

Embodiment 2

[0048] Select non-alkali glass continuous fiber mat (Continuous Fiber Mat, CFM), weight 150g / m 2 , thickness 2.0mm, unwinding by the unwinding roller, impregnated through the resin impregnation tank equipped with unsaturated polyester resin, the unsaturated polyester resin includes: 100 parts by mass of unsaturated polyester; 40 parts by mass of styrene; 1.5 Mass parts methyl ethyl ketone peroxide; 0.5 mass parts mass concentration is 6% cobalt naphthenate solution; When impregnating, make the mass ratio of non-alkali glass continuous fiber felt and unsaturated polyester resin be 50: 50; Impregnating finishes, will obtain The non-alkali glass continuous fiber mat impregnated with resin is heated and pressed to form a substrate by a crawler-type continuous tablet press; the formed substrate is passed through a roller with a scraper with a liquid tank placed above it, and the liquid tank contains The liquid methyl chlorosilane monomer of the initiator is scraped and coated on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com