Melamino-formaldehyde resin encapsulated acetamiprid microcapsule, and preparation method thereof

A technology for coating acetamiprid and melamine, which is applied in the fields of botanical equipment and methods, pesticides, animal husbandry, etc., can solve problems such as decomposition waste, reduce drug dosage, pesticide residues, etc., so as to reduce the harm of solvents, reduce Dialysis, the effect of improving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

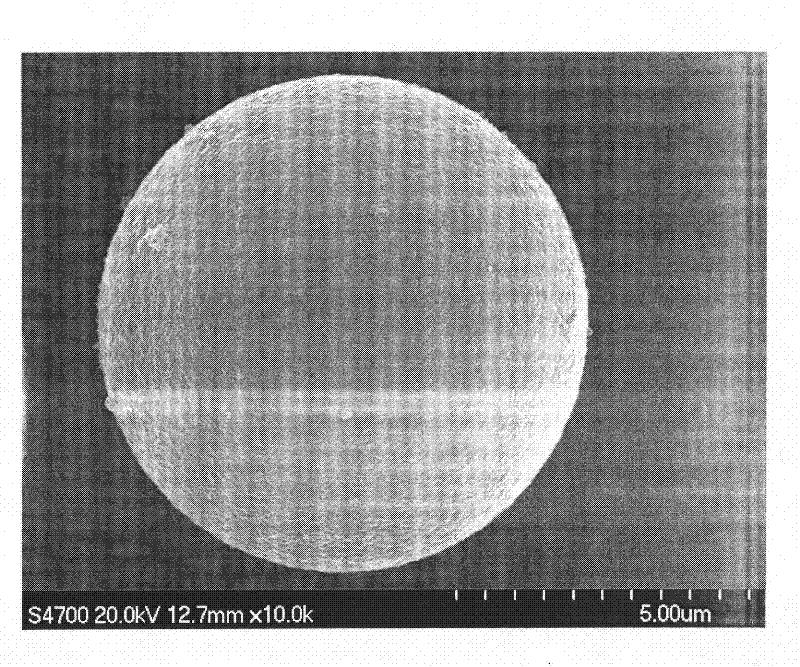

Image

Examples

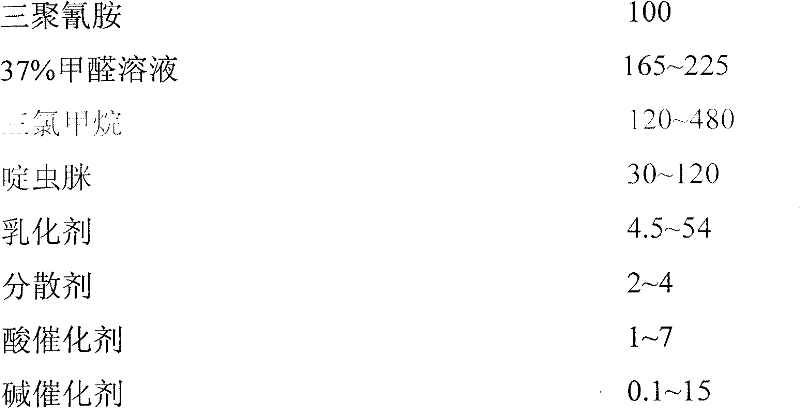

Embodiment 1

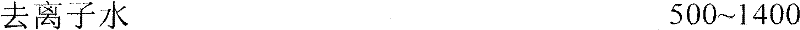

[0028] 1) Put 10g of melamine and 20g of 37% formaldehyde solution into a 250ml three-neck flask, add 1.3g of 1% NaOH solution to adjust the pH value of the system to 8-9, slowly heat up to 65-70°C for 10 minutes and the system becomes transparent, then Add 20 g of distilled water and continue the reaction for 50-60 minutes to obtain a low-molecular-weight transparent melamine-formaldehyde prepolymer.

[0029] 2) Put 6g of acetamiprid and 24g of chloroform into another 250ml three-neck flask, stir to dissolve acetamiprid, then add 3.3g of sodium lauryl sulfate with a mass fraction of 28%, and 60g of distilled water at room temperature Stir at high speed for 30-40 minutes to form a stable O / W pre-emulsion system.

[0030] 3) Pour the pre-emulsion into the melamine formaldehyde prepolymer, stir at a high speed in a water bath at 25-30°C, add 4g of 2% hydrochloric acid solution within 40 minutes to adjust the pH to 4-6, and then add 5% polyethylene as a dispersant to the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com