Amphipathic block copolymer containing polyisobutylene and polyanion and preparation thereof

A polyisobutylene block and amphiphilic block technology is applied in the field of amphiphilic block copolymers and their preparation, and can solve the problems of inability to popularize heterogeneous systems and lack of hydrophilic-lipophilic amphiphilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: PIB-b-PtBMA 53 preparation method

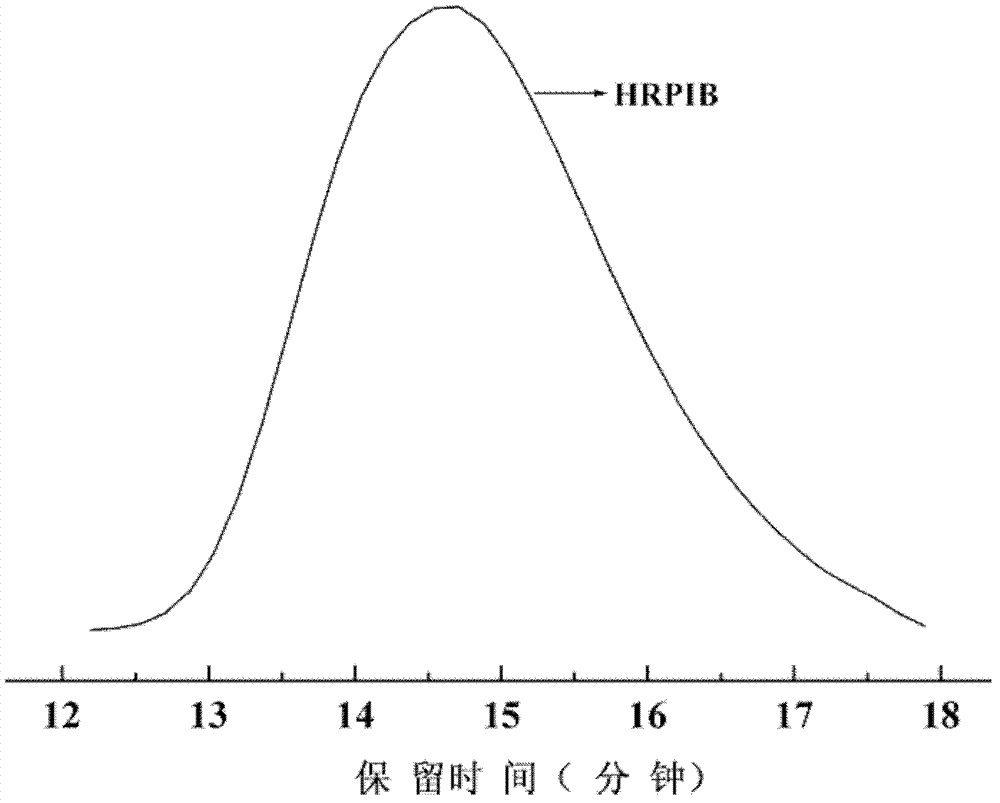

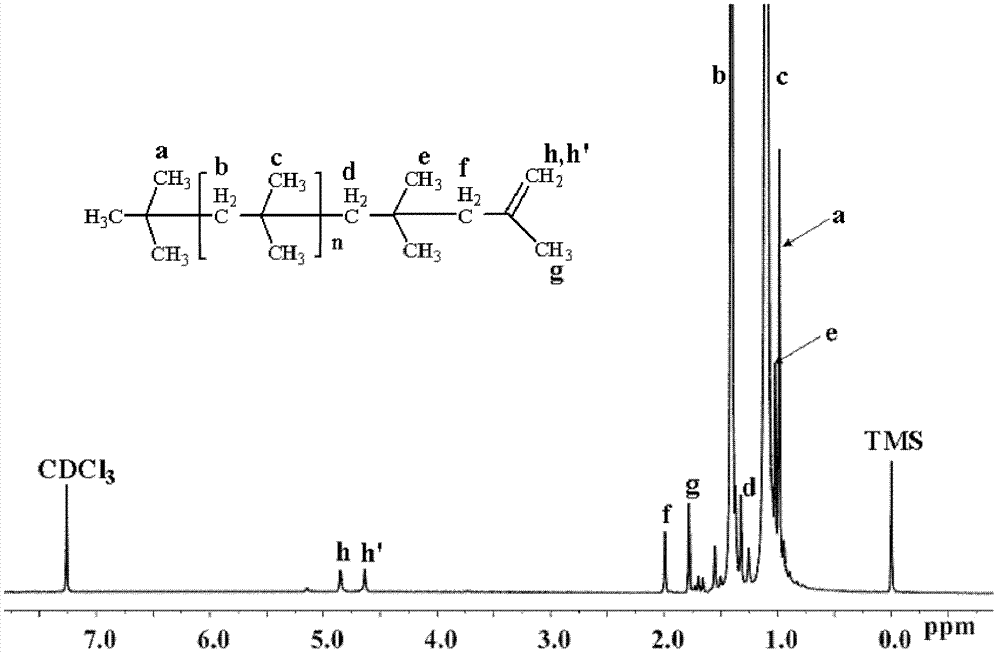

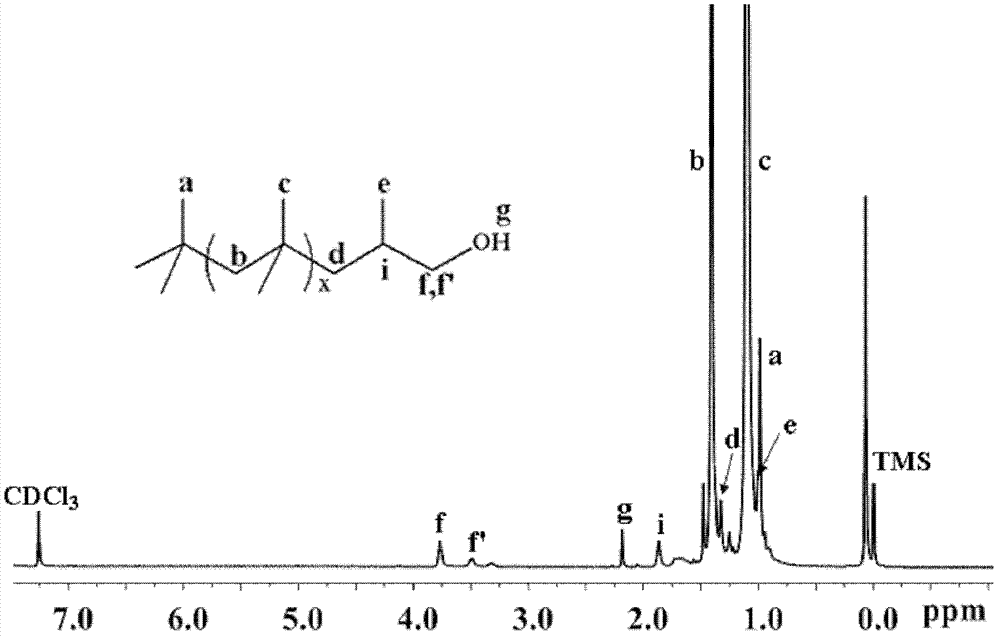

[0077] (1) Preparation of polyisobutylene PIB-OH (HTPIB) containing hydroxyl group (-OH) at the end: under the condition of -5~0℃ ice-water bath, with anhydrous tetrahydrofuran as solvent, add a certain amount of substance into the three-necked flask Sodium borohydride (NaBH 4 ). Boron trifluoride-diethyl ether [(C 2 h 5 O) 2 ·BF 3 ] The solution was reacted for 1.5 hours; then a highly active polyisobutylene (HRPIB) solution dissolved in anhydrous tetrahydrofuran was added dropwise and reacted for 20 hours. Add NaOH solution dropwise, adjust the pH of the system to about 12, slowly add 30% H 2 o 2 solution, reacted for 7 hours. The organic layer was obtained by extraction with ether, and was washed with anhydrous magnesium sulfate (MgSO 4 ) after drying and rotary evaporation to remove the solvent, and the resulting product was dried in a vacuum oven at room temperature for 24 hours to obtain polyisobutylene P...

Embodiment 2

[0087] Embodiment 2: PIB-b-PtBMA 36 preparation method

[0088] (1) Preparation of polyisobutylene PIB-OH (HTPIB) containing hydroxyl group (-OH) at the end: same as Example 1.

[0089] (2) Preparation of KH: same as Example 1.

[0090] (3) Preparation of macroinitiator: same as embodiment one.

[0091] (4) Polymerization reaction: then move the reaction bottle into a constant temperature oil bath at 25°C, add monomer tert-butyl methacrylate (tBMA) with a dry syringe, and the molar ratio to the macromolecular initiator is 40:1, and the reaction 1.0 ~ 1.5h, and finally terminate the reaction with dry methanol. After the reaction, the polymer was removed by rotary evaporation under the condition of 30-40°C, followed by precipitation and purification with cold methanol, repeated three times, and finally dried in a vacuum oven at 40-50°C to constant weight. The desired product was obtained in greater than 98% yield as measured.

[0092] The molecular weight and the molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com