Method for preparing titanium oxide nano wire with self-induction chemical vapor deposition method

A chemical vapor deposition, titanium oxide technology, applied in chemical instruments and methods, from chemically reactive gases, titanium dioxide, etc., can solve the problems of uncertain effects of nanowire performance, inappropriate large-area preparation, template species doping, etc. , to achieve the effect of low equipment requirements, avoiding destructive effects and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

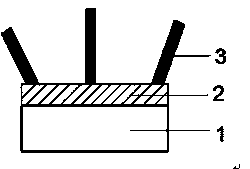

Method used

Image

Examples

Embodiment 1

[0031] Reaction temperature 600 o C, TiCl 4 constant temperature at 40 o C, TiCl 4 The pipeline passed through is insulated to 50 o C, TiCl 4 、SiH 4 and N 2 Mixing, adjust the total gas flow to 1L / min, Si / Ti molar ratio to 1:1, N 2 The volume percentage is 99.6%, the pressure of each gas at the inlet of the gas mixing chamber is 130KPa, the deposition system pressure is maintained at 70KPa, and the deposition time is about 120 seconds. Then turn off the SiH 4 , the TiCl 4 , O 2 and N 2 Mixing, adjust the gas flow rate to 0.8L / min, O / Ti molar ratio to 1:1, N 2 The volume percentage is 99.6%, the growth time is 1 hour, and Ti is formed on the glass substrate 5 Si 3 Thin films and anatase phase TiO 2 Nanowires. See the attached table for the results.

Embodiment 2

[0033] Reaction temperature 750 o C, TiCl 4 constant temperature at 45 o C, TiCl 4 The pipeline passing through is insulated to 60 o C, TiCl 4 、SiH 4 and N 2 Mixing, adjust the total gas flow to 1.5L / min, Si / Ti molar ratio to 2:1, N 2 The volume percentage is 99.1%, the pressure of each gas at the inlet of the gas mixing chamber is 140KPa, the deposition system pressure is maintained at 80KPa, and the deposition time is about 200 seconds. Then turn off the SiH 4 , the TiCl 4 , O 2 and N 2 Mixing, adjust the gas flow rate to 0.5L / min, O / Ti molar ratio to 2:1, N 2 The volume percentage is 99.1%, the growth time is 3 hours, and Ti is formed on the glass substrate 5 Si 3 with TiSi2 Composite thin films and rutile phase TiO 2 Nanowires. See the attached table for the results.

Embodiment 3

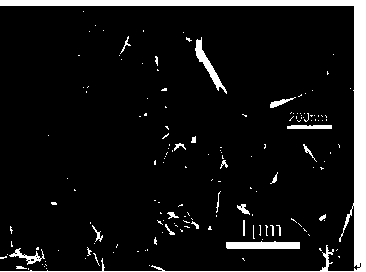

[0035] Reaction temperature 500 o C, TiCl 4 constant temperature at 55 o C, TiCl 4 The pipeline passed through is insulated to 70 o C, TiCl 4 、SiH 4 and N 2 Mixing, adjust the total gas flow to 2.5L / min, Si / Ti molar ratio to 3:1, N 2 The volume percentage is 98.0%, the pressure of each gas at the inlet of the gas mixing chamber is 140KPa, the deposition system pressure is maintained at 100KPa, and the deposition time is about 60 seconds. Then turn off the SiH 4 , the TiCl 4 , O 2 and N 2 Mixing, adjust the gas flow rate to 1L / min, O / Ti molar ratio to 5:1, N 2 The volume percentage is 97.0%, the growth time is 0.5 hours, and TiSi is formed on the glass substrate 2 Thin films and anatase phase TiO 2 Nanowires. See the attached table and figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com