Middle-infrared waveband transmission type sub-wavelength metal grating

A metal grating and infrared band technology, applied in the direction of diffraction gratings, waveguide devices, electrical components, etc., can solve the problem that the infrared window can only transmit waves and cannot filter, etc., and achieves strong controllability of band-pass performance, easy implementation, The effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

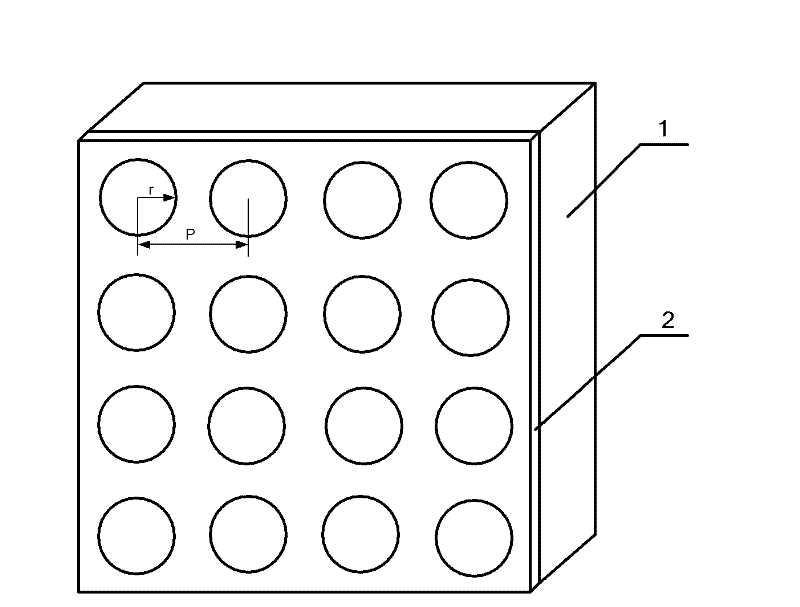

[0024] Example 1. Taking the hole structure on the metal aluminum film as a square array arrangement, the hole period is 6 microns, and the hole diameter is 3 microns as an example:

[0025] ① Clean the substrate, use acetone, alcohol, and deionized water to ultrasonically clean the substrate in sequence, and the ultrasonic cleaning time for each step is about 10 minutes;

[0026] ② Spin-coat AZ5214 reverse photoresist with uniform thickness on the surface of the cleaned substrate by using a glue spinner;

[0027] ③Use a baking board to pre-bake the glue-coated substrate at a temperature of 100 degrees Celsius for 1 minute;

[0028] ④Use a contact type ultraviolet exposure machine to expose the coated substrate, and transfer the periodic hole array pattern on the mask plate to the photoresist under the ultraviolet light source, and the exposure time is 2.5 seconds;

[0029] ⑤ Post-baking the exposed substrate with a baking plate to convert the negative photoresist into a posi...

example 2

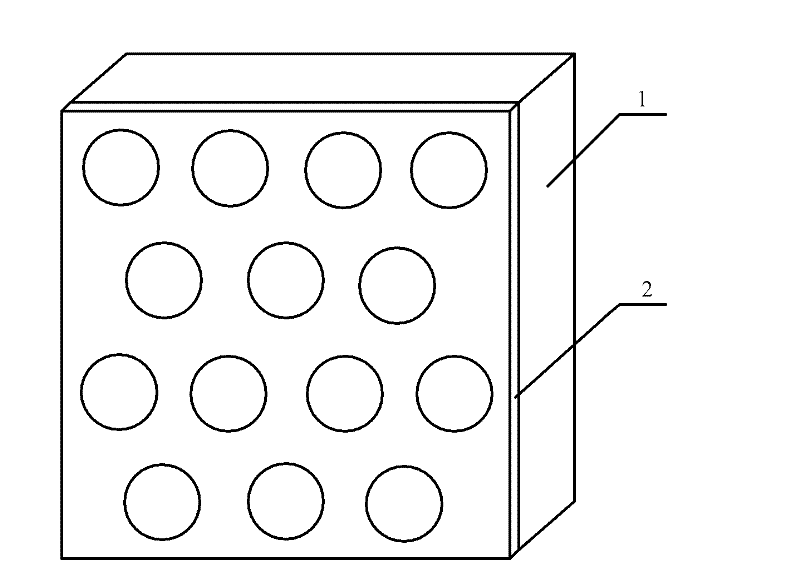

[0034] Example 2. Take the hole structure on the metal aluminum film arranged in a hexagonal array, the array period is 6 microns, and the hole diameter is 3 microns as an example:

[0035] Except step ④, other steps are the same as Example 1. In this example, the patterns on the photolithography mask used in step ④ are arranged in a hexagonal hole array structure.

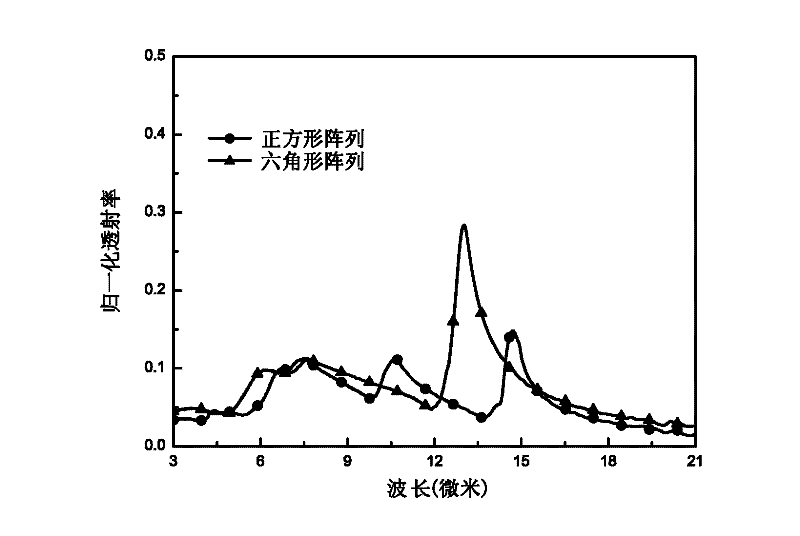

[0036] For the above two mid-infrared band transmissive sub-wavelength metal grating samples, the infrared transmittance curves were tested by Fourier transform infrared spectrometer, as shown in image 3 As shown: the metal grating with the hexagonal array structure achieves a transmission peak with a transmittance of about 30% at 12 to 15 microns (about 2.2 times the array period), and the metal grating with the square array structure at 13 to 16 microns (about 2.2 times the array period). 2.5 times the array period), a transmission peak with a transmittance of about 18% is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com