Preparation method of super-micro molecular iron dextran

A technology of ultra-micromolecular dextran and molecular dextran, which is applied in the field of preparation technology of glucose polymer and iron dextran to achieve the effects of shortening complexation time, reducing production costs and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

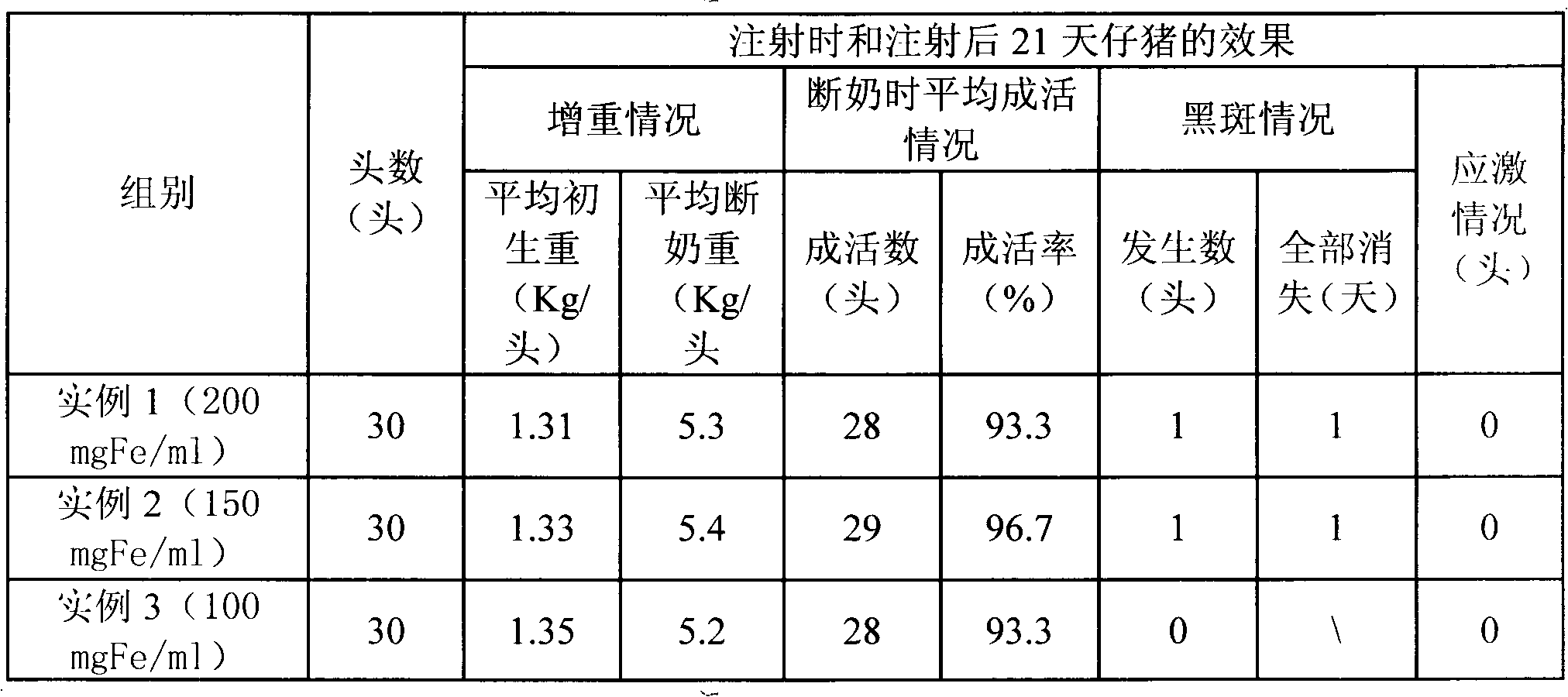

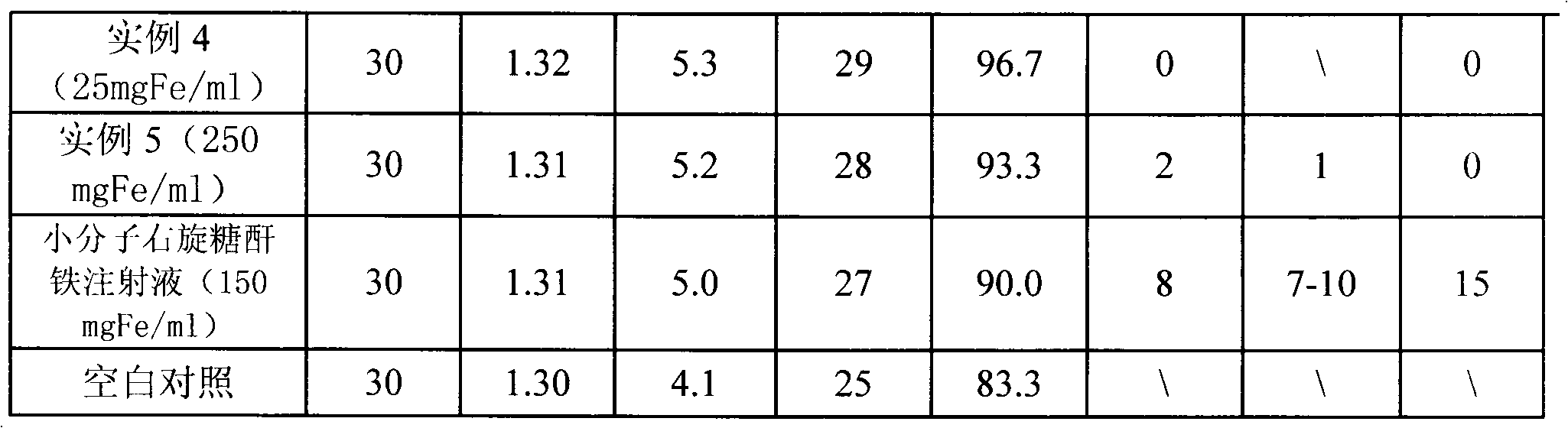

Examples

example 1

[0025] (1) Application of hydrogen peroxide / alkali solution to oxidize ultra-fine molecular dextran

[0026] In a 500ml three-necked flask heated with a stirrer and a water bath, add 18g of ultra-micromolecular dextran (weight average molecular weight of 3000-6000Da) and 40ml of purified water, start the stirrer, heat up to 80°C, gelatinize for 20 minutes, and then add 7g , 30% sodium hydroxide solution, then add 9ml, 20% hydrogen peroxide solution, after adding, react for 50 minutes to obtain an orange-red solution, and then reduce the solution temperature to room temperature, neutralize it with 6N hydrochloric acid solution to pH is 4.0-5.0, the oxidized ultra-micromolecule dextran solution is obtained.

[0027] (2) Preparation of ultra-micromolecular iron dextran

[0028] The oxidized ultra-micromolecule dextran solution prepared by the above method is heated to 80 ° C while stirring, and 100 ml of 35% ferric chloride solution and 80 ml of 30% sodium hydroxide solution are...

example 2

[0031] (1) Application of hydrogen peroxide / alkali solution to oxidize ultra-fine molecular dextran

[0032] In a 500ml three-necked flask heated with a stirrer and a water bath, add 18g of ultra-micromolecular dextran (weight average molecular weight of 3000-6000Da) and 35ml of purified water, start the stirrer, heat up to 60°C, gelatinize for 40 minutes, and then add 9g , 20% sodium hydroxide solution, then add 6ml, 25% hydrogen peroxide solution, after adding, react for 30 minutes to obtain an orange-red solution, and then reduce the solution temperature to room temperature, neutralize it with 6N hydrochloric acid solution to pH is 4.0-5.0, the oxidized ultra-micromolecule dextran solution is obtained.

[0033] (2) Preparation of ultra-micromolecular iron dextran

[0034]The oxidized ultrafine molecular dextran solution prepared by the above method was heated up to 65°C while stirring, and 120ml of 35% ferric chloride solution and 83ml of 35% sodium hydroxide solution were...

example 3

[0037] (1) Application of hydrogen peroxide / alkali solution to oxidize ultra-micromolecular dextran

[0038] In a 500ml three-necked flask equipped with a stirrer and heated by a water bath, add 18g of ultra-micromolecular dextran (weight average molecular weight 3000-6000Da) and 70ml of purified water, start the stirrer, heat up to 70°C, gelatinize for 30 minutes, and then add 6g , 40% sodium hydroxide solution, then add 2ml, 27% hydrogen peroxide solution, after the addition, react for 20 minutes to obtain an orange-red solution, then lower the solution temperature to room temperature, and neutralize it to pH with 6N hydrochloric acid solution If it is 4.0-5.0, an oxidized ultramicromolecular dextran solution is obtained.

[0039] (2) Preparation of Ultrafine Molecular Iron Dextran

[0040] The oxidized ultramicromolecular dextran solution prepared by the above method was heated up to 90°C while stirring, and 90ml of 30% ferric chloride solution and 75ml of 25% sodium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com