Method for preparing bioactive glass ceramic material for bone defect restoration

A technology of bioactive glass and bioglass, applied in medical science, prosthesis, etc., can solve the problems of high brittleness and low mechanical strength, and achieve the effect of large output, good mechanical strength, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

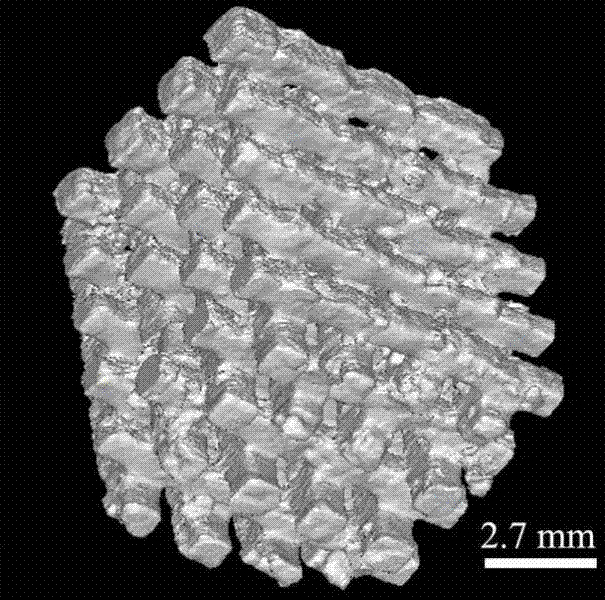

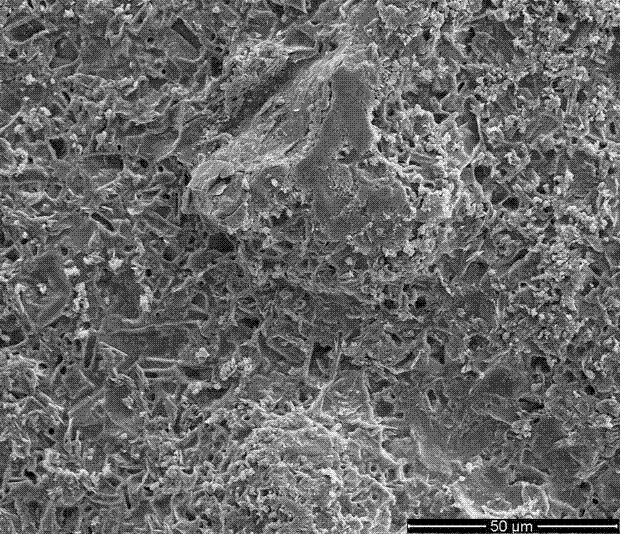

Image

Examples

Embodiment 1

[0034] Using Na 2 O-CaO-SiO 2 -P 2 o5 Bioglass powder.

[0035] (1) After fully mixing 58.63g sodium carbonate, 52.33g calcium carbonate, 18.36g tricalcium phosphate and 63.00g silicon dioxide, put them into a platinum crucible and melt at 1400°C for 120min, then pour the molten glass into deionized water Quenching with water to obtain amorphous phase bioactive glass. After filtering out the water, dry in an electric blast drying oven at 60°C for 24 hours, ball mill in a planetary ball mill at a speed of 480rpm for 3 hours, and pass through a 200-mesh sieve to obtain Na 2 O-CaO-SiO 2 -P 2 o 5 Biological glass powder, each material is composed of: 24.5% calcium oxide, 6g phosphorus pentoxide, 24.5% sodium oxide, 45% silicon dioxide;

[0036] (2) Add 100g Na 2 O-CaO-SiO 2 -P 2 o 5 The bio-glass powder was added to 100mL polyacrylamide solution with a volume fraction of 6%, and ball milled for 3 hours to mix to obtain a bio-glass slurry with a volume fraction of 50%;

...

Embodiment 2

[0040] Using Na 2 O-CaO-SiO 2 -P 2 o 5 Bioglass powder and CaO-SiO 2 -P 2 o 5 A mixture of bioglass powders, where Na 2 O-CaO-P 2 o 5 -SiO 2 The mass fraction of biological glass powder is 99%, CaO-P 2 o 5 -SiO 2 The mass fraction of biological glass powder is 1%.

[0041] (1) Mix 59.82g of sodium carbonate, 53.40g of calcium carbonate, 15.30g of tricalcium phosphate and 63.00g of silicon dioxide, put them into a platinum crucible and melt at 1400°C for 120min, then pour the molten glass into deionized Quenching in water to obtain amorphous phase bioactive glass, after filtering out the water, dry in an electric blast drying oven at 60°C for 24h, ball mill in a planetary ball mill at a speed of 480rpm for 3h, and pass through a 200-mesh sieve to obtain Na 2 O-CaO-SiO 2 -P 2 o 5 Biological glass powder, each material is composed of: 25% calcium oxide, 5g phosphorus pentoxide, 25% sodium oxide, 45% silicon dioxide;

[0042] (2) Add 18.72mL of deionized water, 3....

Embodiment 3

[0047] Using Na 2 O-CaO-SiO 2 -P 2 o 5 Bioglass powder and CaO-SiO 2 -P 2 o 5 A mixture of bioglass powders, where Na 2 O-CaO-P 2 o 5 -SiO 2 The mass fraction of biological glass powder is 50%, CaO-P 2 o 5 -SiO 2 The mass fraction of biological glass powder is 50%.

[0048] (1)) After fully mixing 39.32g sodium carbonate, 35.09g calcium carbonate, 13.11g tricalcium phosphate and 48.00g silicon dioxide, put them into a platinum crucible and melt at 1400°C for 120min, then pour the molten glass into Quenching in ionized water to obtain amorphous phase bioactive glass. After filtering the water, dry it in an electric blast drying oven at 60°C for 24 hours, ball mill it in a planetary ball mill at a speed of 480rpm for 3 hours, and pass through a 200-mesh sieve to obtain Na 2 O-CaO-SiO 2 -P 2 o 5 Biological glass powder, the composition of each material is: 23% calcium oxide, 6% phosphorus pentoxide, 23% sodium oxide and 48% silicon dioxide;

[0049] (2) Add 93.6m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com