Fluorinated weather-resistant film for solar photovoltaic battery back plate and preparation method of fluorinated weather-resistant film

A photovoltaic cell and solar energy technology, applied in the field of solar photovoltaic power generation, can solve the problems of low longitudinal tear strength of the film, inconsistent film elasticity at both ends, high water vapor transmission rate, etc., and achieve excellent weather resistance, fast plasticization, heat Small shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

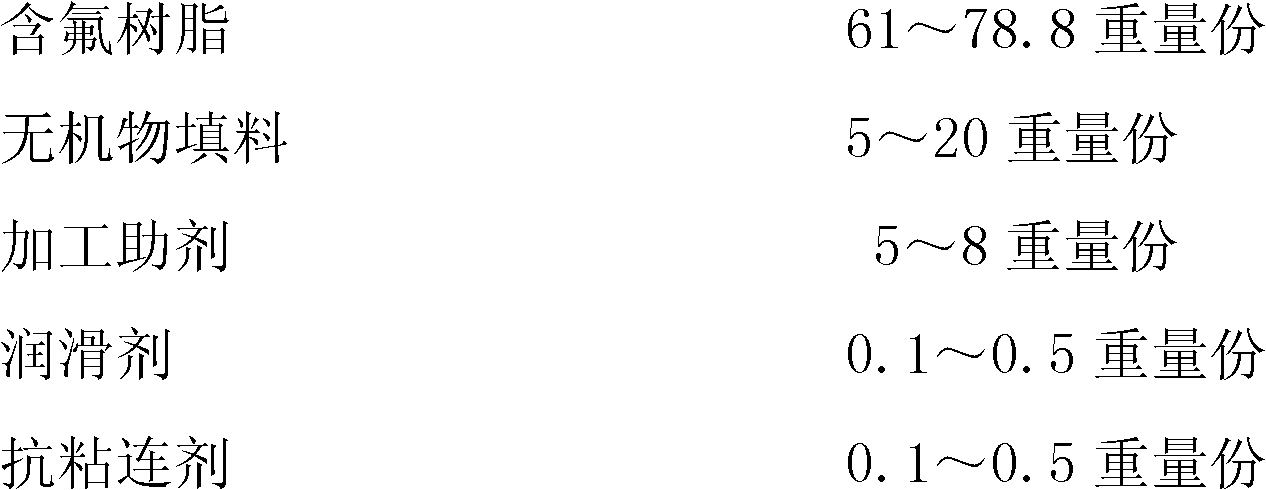

[0027] In embodiment 1, the fluorine-containing resin used is polyvinylidene fluoride (PVDF), and molecular weight is 690,000; The inorganic matter filler used is titanium dioxide, and average particle diameter is 0.2 micron; Used processing aid is Rohm and Haas Company The combination of methacrylate processing aids Paraloid K120 and Paraloid K400; the lubricant used is polyethylene wax; the anti-blocking agent used is erucamide; the flow modifier used is dioctyl terephthalate (DOP). The raw material formula of embodiment 1 is as follows:

[0028]

[0029] The fluorine-containing weather-resistant film in Example 1 was prepared according to the following steps:

[0030] (1) Use a high-speed mixer to uniformly mix the raw material formula to obtain a mixture. The stirring rate of the high-speed mixer is 400rpm.

[0031] (2) Then use a twin-screw extruder to transport, plasticize, blend and granulate the compound described in step (1) to obtain a granulated material. The...

Embodiment 2

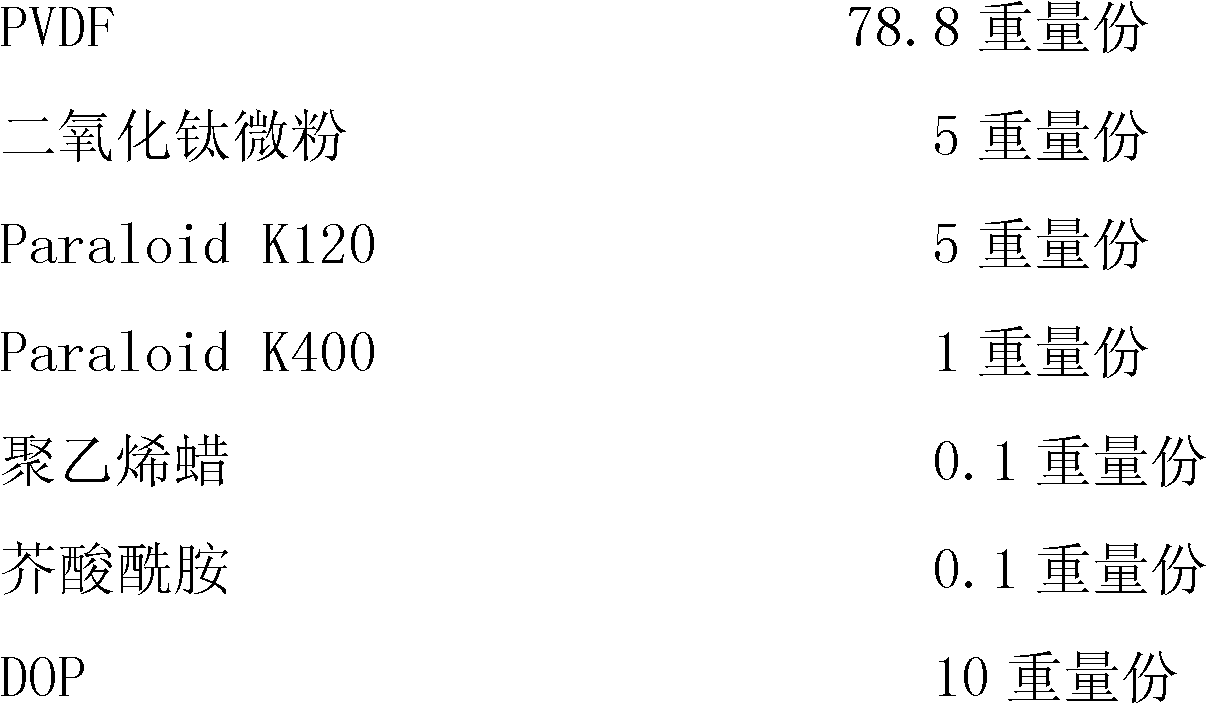

[0034] In Example 2, the fluorine-containing resin used is a combination of polyvinylidene fluoride (PVDF) and vinylidene fluoride-hexafluoropropylene (PVDF-HFP) copolymer, the molecular weight of PVDF is 250,000, and the molecular weight of PVDF-HFP is 790,000; The inorganic filler used is calcium carbonate, and the average particle size is 0.1 micron; The processing aid used is the combination of the methacrylate processing aid Paraloid K175 and Paraloid K125 of Rohm and Haas; The lubricant used is chlorine The anti-blocking agent used is EBS; the flow modifier used is diisooctyl phthalate (DIOP). The raw material formula of embodiment 2 is as follows:

[0035]

[0036] The fluorine-containing weather-resistant film in Example 2 was prepared according to the following steps:

[0037] (1) Use a high-speed mixer to uniformly mix the raw material formula to obtain a mixture. The stirring rate of the high-speed mixer is 850rpm.

[0038] (2) Then use a twin-screw extruder t...

Embodiment 3

[0041] In embodiment 3, the fluororesin used is ethylene-chlorotrifluoroethylene copolymer (ECTFE), and ECTFE molecular weight is 250,000; The inorganic matter filler used is titanium dioxide, and average particle diameter is 0.2 micron; Used processing aid is The methacrylate processing aid Paraloid K400 of Rohm and Haas Company; The lubricant used is paraffin; The anti-blocking agent used is a silicone masterbatch, produced by Dow Chemical Company of the United States. The raw material formula of embodiment 3 is as follows:

[0042]

[0043] The fluorine-containing weather-resistant film in Example 3 was prepared according to the following steps:

[0044] (1) Use a high-speed mixer to uniformly mix the raw material formula to obtain a mixture. The speed of the high speed mixer was 1300 rpm.

[0045] (2) Then use a twin-screw extruder to transport, plasticize, blend and granulate the compound described in step (1) to obtain a granulated material. The aspect ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com