Composite corrosion and scale inhibitor and its application in water treatment

A technology of corrosion and scale inhibitors and scale inhibitors and dispersants, which is applied in water/sludge/sewage treatment, scale removal and water softening, chemical instruments and methods, etc., to achieve good comprehensive performance, less dosage, and reduced harm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

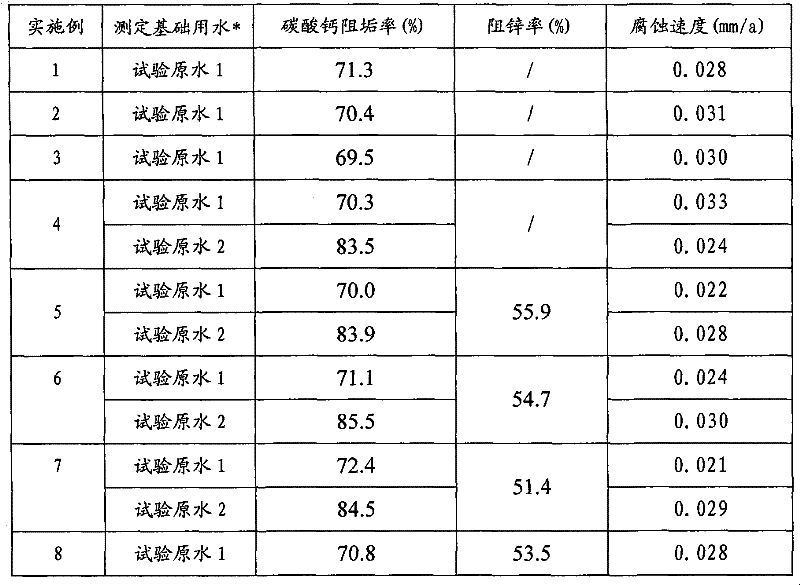

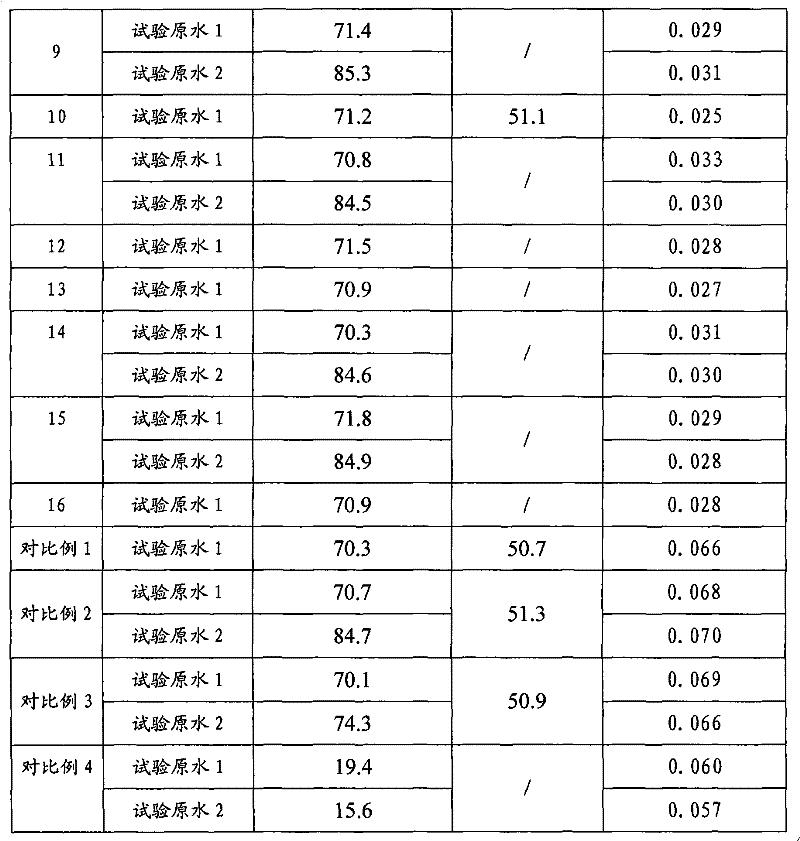

Examples

Embodiment 1

[0053] Take by weighing 12.0g sodium gluconate respectively, 66.9g sodium tetraborate pentahydrate, 60.0g solid content is 30% acrylic acid / hydroxypropyl acrylate / methyl acrylate (MA) copolymer (limit viscosity number is 0.078dl when 30 ℃ / g, AA / HPA / MA=60 / 20 / 20 (weight ratio, the same below)), the active ingredient is 50% 2-phosphonic acid group-1,2,4-butane tricarboxylate (PBTCA) 5.0g, add 56.1g of water and shake well to obtain 200.0g of the required preparation.

[0054] When the prepared medicament is added to test raw water 1 and test raw water 2, corrosion inhibition test water 1 (adjust the pH value to 7.9 with sulfuric acid) and test water 2 at a concentration of 200 mg / L, the sodium gluconate, five The effective concentrations of sodium tetraborate hydrate, PBTCA, and acrylic acid / hydroxypropyl acrylate / methyl acrylate copolymer were 12 mg / L, 35 mg / L, 2.5 mg / L, and 18 mg / L, respectively.

Embodiment 2

[0056] Take by weighing 30.5g anhydrous sodium metasilicate, 55.0g sodium gluconate, 33.3g 30% acrylic acid / 2-methyl-2'-acrylamidopropanesulfonic acid binary copolymer (at 30 DEG C, the limiting viscosity is 0.074dl / g, AA / AMPS=70 / 30), the active ingredient is 50% HEDP7.0g, add to 74.2g water, shake well, promptly obtain the required preparation 200.0g medicine solution.

[0057] When the prepared chemical solution is added to the test raw water 1 and the corrosion inhibition test water 1 (with sulfuric acid to adjust the pH value to 8.0) at a concentration of 200mg / L, the anhydrous sodium metasilicate, sodium gluconate, HEDP The effective concentrations of acrylic acid / 2-methyl-2'-acrylamidopropanesulfonic acid binary copolymer are 15mg / L, 55mg / L, 3.5mg / L and 10mg / L, respectively.

Embodiment 3

[0059] Take by weighing 36.9g sodium tetraborate decahydrate, 194.1g sodium metasilicate pentahydrate, 13.3g 30% methyl acrylate / styrene sulfonic acid copolymer (limited viscosity number is 0.074dl / g when 30 ℃, MA / benzene Ethylene sulfonic acid=80 / 20), the active ingredient is 7.0 g of 50% glycine dimethylphosphonic acid, added to 148.7 g of water, and shaken up to obtain 400.0 g of the medicament solution to be prepared.

[0060] When the prepared chemical solution is added to the test raw water 1 and the corrosion inhibition test water 1 (with sulfuric acid to adjust the pH value to 8.1) at a concentration of 400mg / L, the sodium tetraborate decahydrate and sodium metasilicate pentahydrate in the water will The effective concentrations of glycine dimethylene phosphonic acid and methyl acrylate / styrene sulfonic acid copolymer are 15mg / L, 55mg / L, 3.5mg / L and 4mg / L, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com