Preparation method of high-softening-point asphalt particles for drilling fluid

A technology of high softening point bitumen and drilling fluid, which is applied in chemical instruments and methods, chemically processing tar pitch/petroleum pitch/natural pitch, drilling compositions, etc., can solve the problem of low reaction efficiency, long reaction time, The problem of high temperature sensitivity of the product can achieve the effects of high reaction efficiency, convenient operation, excellent high temperature performance and temperature resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

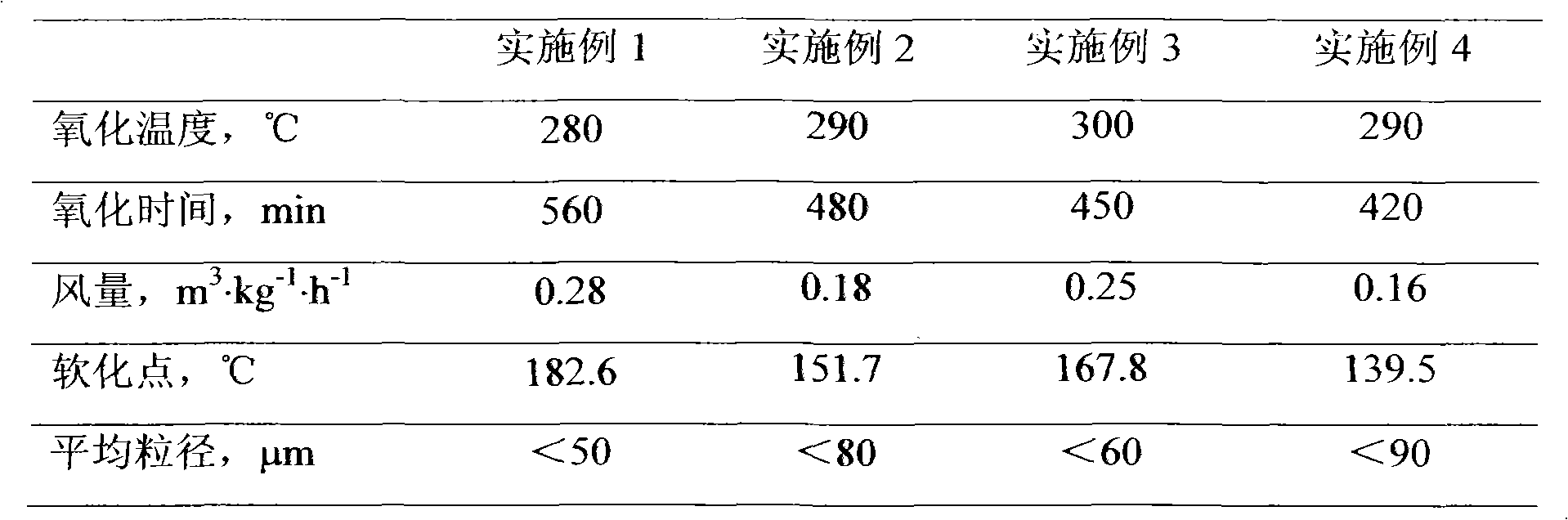

Embodiment 1

[0034] Heat the vacuum residue with a penetration of 116 1 / 10mm at 25°C and a softening point of 41.5°C, accounting for 96.2% (m) of the total amount, to a molten state at 150°C, and add 1.2% (m) of ferric chloride And 2.6% (m) of polyphosphoric acid and pass into the air, the flow rate is 0.1m 3 kg -1 h -1 , use a high-shear mixing emulsifier to shear for 30 minutes, and enter the oxidation tower for blowing oxidation to obtain high softening point asphalt products.

[0035] Put 100g of high softening point asphalt in a closed container, add 1.0 times of light naphtha as a solvent, heat to 190°C, feed nitrogen to control the pressure of the container at 8.5MPa, and keep it for 30min. The mixture is put into a separator through a throttle valve to obtain high softening point bitumen granules.

Embodiment 2

[0037] Heat the vacuum residue with a penetration of 1711 / 10mm at 25°C and a softening point of 37.2°C, accounting for 95.4% (m) of the total amount, to a molten state of 140°C, and add 0.8% (m) of zinc oxide, 0.8 % (m) of copper sulfide and 3.0% (m) of polyphosphoric acid and pass into the air, the flow rate is 0.1m 3 kg -1 h -1 , use a high-shear mixing emulsifier to cut for 30 minutes, and enter the oxidation tower for blowing oxidation to obtain high softening point asphalt.

[0038] Put 100g of high softening point asphalt in a closed container and add 0.6 times of mixed solvent, wherein n-butane accounts for 70% and isobutane accounts for 30%. Heat to 160°C, feed nitrogen to control the pressure of the container at 6.0MPa, and keep it for 25min. The mixture is put into a separator through a throttle valve to obtain high softening point bitumen granules.

Embodiment 3

[0040] Heat the vacuum residue with a penetration of 1481 / 10mm at 25°C and a softening point of 39.5°C, accounting for 95.4% (m) of the total amount, to a molten state at 150°C, and add 0.8% (m) of ferric chloride, 0.6% (m) of zinc oxide and 3.2% (m) of polyphosphoric acid are fed into the air with a flow rate of 0.2m 3 kg -1 h -1 , use a high-shear mixing emulsifier to cut for 30 minutes, and enter the oxidation tower for blowing oxidation to obtain high softening point asphalt.

[0041] Put 100g of high softening point asphalt in a closed container and add 0.8 times of mixed solvent, wherein n-butane accounts for 40%, and isopentane accounts for 60%. Heat to 170°C, pass nitrogen gas to control the pressure of the container at 7.0MPa, and keep it for 25min. The mixture is put into a separator through a throttle valve to obtain high softening point bitumen granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com