Solid-phase micro-extraction coating prepared on basis of polydopamine modified stainless steel wires and preparation method and application thereof

A stainless steel wire, polydopamine technology, applied in chemical instruments and methods, other chemical processes, material separation, etc., can solve problems such as difficulty in controlling coating thickness, and achieve long service life, good preparation reproducibility, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

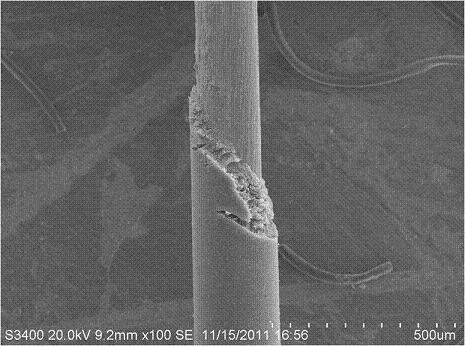

[0028] (1) After polishing and cleaning the front end 1cm-2cm of a stainless steel wire with a diameter of 0.22mm and a length of 10cm, soak it in 10 mL of 10 mmol / L Tris buffer solution containing 20 mg of dopamine, and adjust its pH to 8.5. After 20 hours, the stainless steel wire Take out the wire, rinse the front end with deionized water, and use N 2 blow dry.

[0029] (2) Take 40mmol of ethyl acetate, 1mmol of methacrylic acid, 4mmol of ethylene glycol dimethacrylate and 1mmol of azobisisobutyronitrile in a centrifuge tube and mix them evenly. 2 Oxygen was removed for 10 minutes.

[0030] (3) After cleaning, a quartz capillary with an inner diameter of 0.25 mm and a length of 5 cm was inserted into the above-mentioned pre-polymerization solution. Due to capillary action, the pre-polymerization solution filled the capillary, and then the polydopamine-modified stainless steel wire was inserted into the capillary, and immediately Seal both ends of the capillary with a rubb...

Embodiment 2

[0042] The basic operation is the same as in Example 1, but the pre-polymerization solution is a mixed solvent of 20mmol ethyl acetate, 2mmol methacrylic acid, 1mmol ethylene glycol dimethacrylate and 2mmol azobisisobutyronitrile. The rest of the treatments are the same.

Embodiment 3

[0044] The basic operation is the same as in Example 1, but the pre-polymerization solution is a mixed solvent of 30mmol ethyl acetate, 1.6mmol methacrylic acid, 2mmol ethylene glycol dimethacrylate and 1.6mmol azobisisobutyronitrile. The rest of the treatments are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com