Special melt granulation fertilizer for leaf vegetables and preparation method thereof

A technology of melt granulation and leafy vegetables, which is applied in the field of special fertilizers for leafy vegetables and its preparation, can solve the problems of small-scale compound fertilizers, serious pollution, and large investment, so as to improve crop quality, reduce energy consumption, and save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064]Melt 450kg of urea at 135°C at high temperature, and pump it into the mixing tank at the top of the tower; 250kg of potassium sulfate heated to 120°C, 200kg of monoammonium phosphate heated to 110°C, 10kg of calcium sulfate, 10kg of magnesium sulfate, and 10kg of manganese sulfate , 10kg of zinc sulfate, 10kg of borax, 5kg of sodium nitrophenolate, and 45kg of talcum powder are measured together, and then sent to the mixer to fully mix evenly; after crushing, send it to the top warehouse with a bucket elevator; In the melting tank, stir and mix into a thick liquid liquid, the temperature is controlled at 115°C; send it to the differential nozzle, spray and granulate in the high tower, the diameter of the granular material at the bottom of the tower is 2mm, the temperature of the granular material is about 60°C, and cool to 40 °C to obtain the special fertilizer for melt granulation leaf vegetables.

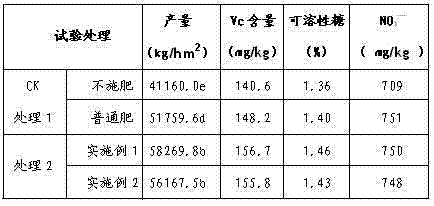

[0065] The prepared special fertilizer for melt granulation leaf vegeta...

Embodiment 2

[0067] Melt 400kg of urea at 133°C at high temperature, and pump it into the mixing tank at the top of the tower; 300kg of potassium sulfate, 200kg of monoammonium phosphate, 15kg of calcium sulfate, 10kg of magnesium sulfate, 10kg of zinc sulfate, 15kg of borax, 5kg of sodium nitrophenolate, Talcum powder 45kg is sent into the stirrer after metering together and fully mixes; Following process is with embodiment 1.

[0068] The prepared special fertilizer for melt granulation leaf vegetables contains nitrogen, phosphorus and potassium (N-P 2 o 5 -K 2 O) The ratio is 21-9-15, the total nutrients are 45%, and the calcium, magnesium, sulfur, zinc, and boron are greater than or equal to 0.3%, 0.1%, 0.6%, 0.2%, and 0.1%, respectively. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com