Anaerobic treatment process for high-concentration kitchen waste

A technology for food waste and anaerobic treatment, which is applied in the direction of solid waste removal, etc., can solve the problems of excessive ammonia nitrogen concentration and salt concentration in anaerobic reactors, unbalanced coupling metabolism of anaerobic bacteria, unfavorable growth of anaerobic microorganisms, etc. , to achieve the effect of reducing waste, avoiding reactor failure, and improving stability and sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

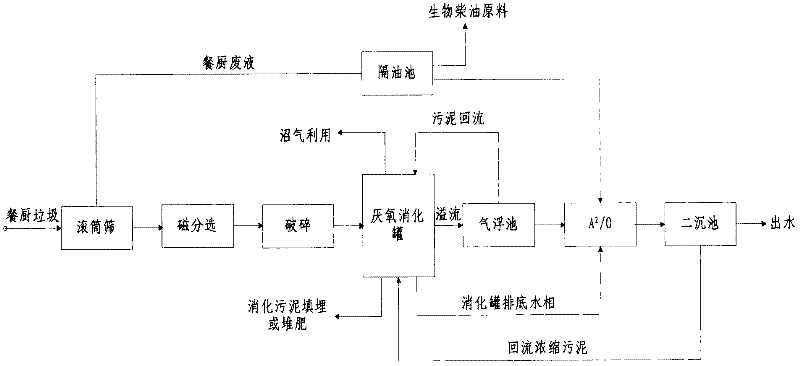

[0028] Collect swill and kitchen waste from nearby restaurants, about 5 t / d, with a solid content of 21%, and first pass through an 80-mesh drum sieve for solid-liquid separation to obtain solid and liquid kitchen waste.

[0029] The kitchen waste liquid enters the grease trap, and the top waste oil is collected as biodiesel raw material, and the lower water phase enters the A 2 / O process for nitrogen removal.

[0030] The solid-phase kitchen adopts magnetic separation method for preliminary separation to separate the metal impurities. The sorted garbage enters the TS320 crusher, and the crushed slurry is sent to the anaerobic digestion tank together with the return sludge of the secondary settling tank and the air flotation tank. The digestion time is 12 days; the overflow of the digested slurry enters the air flotation tank; , the discharged sludge is transported to landfill or composted after mechanical dehydration, and the digestive juice enters A 2 / O process. Under t...

Embodiment 2

[0033] Collect swill and kitchen waste from nearby restaurants, about 5 t / d, with a solid content of 21%, and first pass through an 80-mesh drum sieve for solid-liquid separation to obtain solid and liquid kitchen waste.

[0034] The kitchen waste liquid enters the grease trap, and the top waste oil is collected as biodiesel raw material, and the lower water phase enters the A 2 / O process for nitrogen removal.

[0035] The solid-phase kitchen adopts magnetic separation method for preliminary separation to separate the metal impurities. The sorted garbage enters the TS320 crusher, and the crushed slurry is sent to the anaerobic digestion tank together with the return sludge of the secondary settling tank and the air flotation tank. The digestion time is 16 days; the overflow of the digested slurry enters the air flotation tank; the bottom is discharged intermittently at regular intervals , the discharged sludge is transported to landfill or composted after mechanical dehydrat...

Embodiment 3

[0038] Collect swill and kitchen waste from nearby restaurants, about 5 t / d, with a solid content of 21%, and first pass through an 80-mesh drum sieve for solid-liquid separation to obtain solid and liquid kitchen waste.

[0039] The kitchen waste liquid enters the grease trap, and the top waste oil is collected as biodiesel raw material, and the lower water phase enters the A 2 / O process for nitrogen removal.

[0040] The solid-phase kitchen adopts magnetic separation method for preliminary separation to separate the metal impurities. The sorted garbage enters the TS320 crusher, and the crushed slurry is sent to the anaerobic digestion tank together with the return sludge of the secondary sedimentation tank and the air flotation tank. The digestion time is 20 days; the overflow of the digested slurry enters the air flotation tank; the bottom is discharged intermittently at regular intervals , the discharged sludge is transported to landfill or composted after mechanical deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com