Preparation method of porous calcium carbonate crystal particle having nanometer cone microstructure

A technology of porous calcium carbonate and microstructure, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of block copolymers not being naturally degradable, environmental protection, complicated routes, and deviation from bionic routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

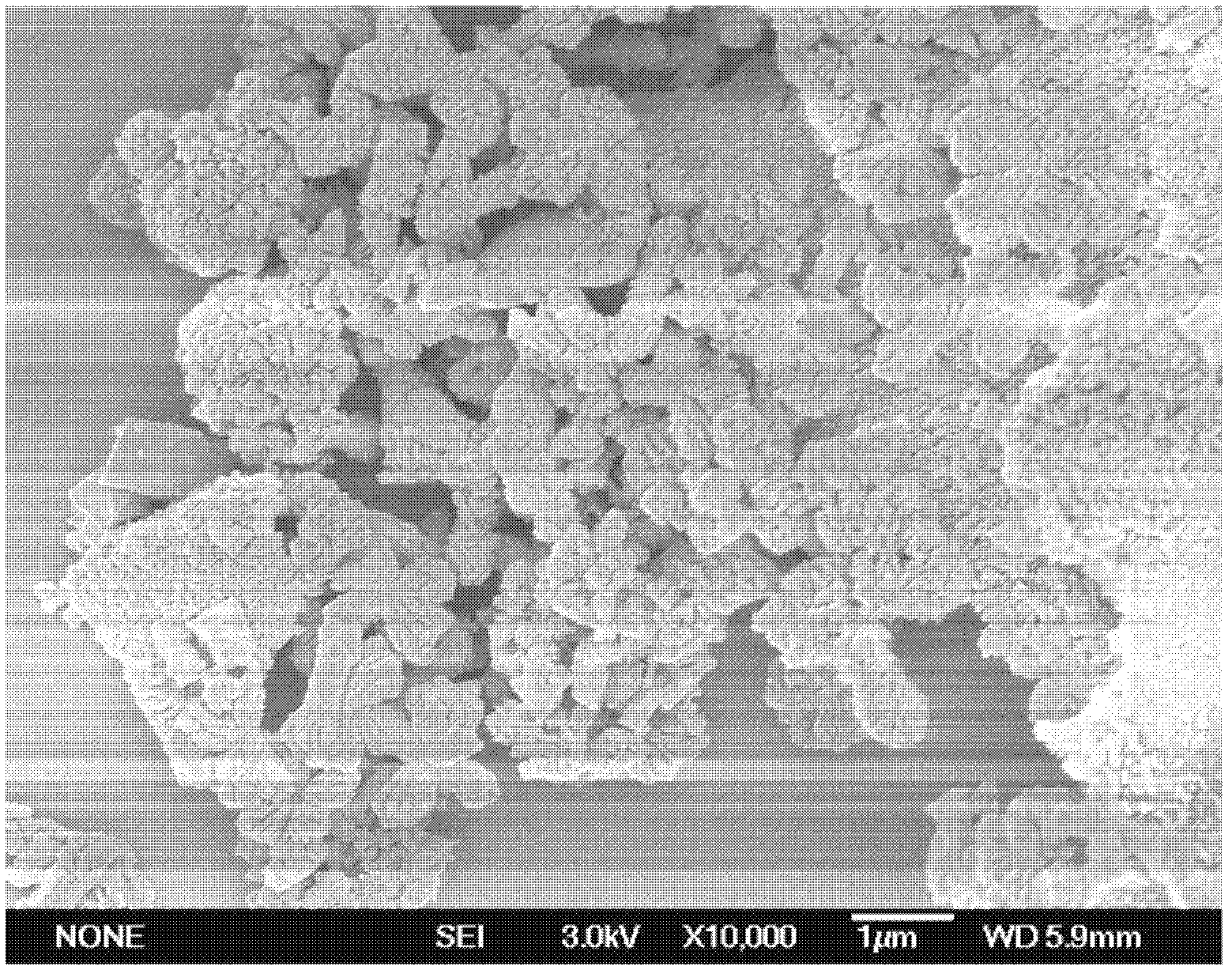

[0034]After the 1L glass beaker is cleaned up, the preparation concentration is 0.02g / L sulfonated polyaspartic acid derivative (this sulfonated polyaspartic acid derivative refers to the literature (Macromolecular Materials Science and Engineering, 2008, 24, 44-50) is prepared by reacting taurine with polysuccinimide, m / n=40 / 100) aqueous solution 950ml, under stirring, adjust the pH value of the aqueous solution of sulfonated polyaspartic acid derivatives to 5 with hydrochloric acid, Inject 10ml of 2mol / L calcium hydroxide aqueous solution, stir evenly, and continue to inject 10ml of 2mol / L sodium carbonate aqueous solution; after the injection is completed, stand and age at room temperature and dustproof for 5 hours, separate and dry the solid product to obtain rod-shaped and spherical The main particle size or length dimension is 1-3μm, with a specific surface area of 10-30m with a regular triangle with a side length of about 400nm as the base 2 / g of porous calcium carbo...

Embodiment 2

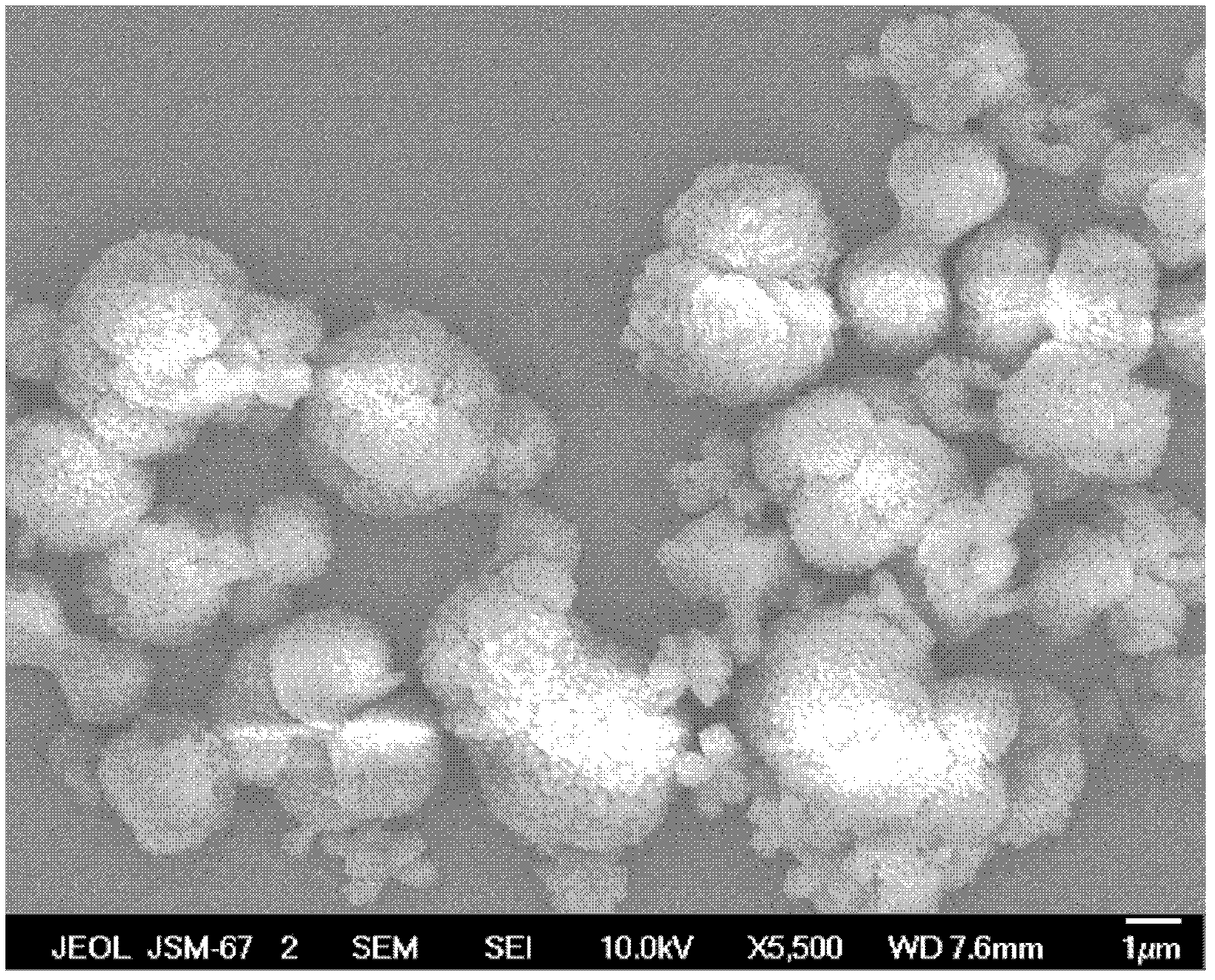

[0037] After cleaning the 1L glass beaker, prepare hydroxylated polyaspartic acid with a concentration of 4g / L (the molar ratio of hydroxylamine to polyaspartic acid is 1:10; 2 o 5 Carry out amidation reaction preparation for dehydrating agent, m / n=10 / 100) aqueous solution 500ml, adjust the pH value of hydroxylated polyaspartic acid aqueous solution to be 8 with aqueous sodium hydroxide solution under stirring, inject the calcium nitrate of 0.2mol / L 250ml of aqueous solution, after stirring evenly, continue to inject 250ml of 0.2mol / L potassium carbonate aqueous solution; after the injection is completed, stand and age at room temperature and dustproof for 150 hours, separate and dry the solid product, and obtain the particle size or length mainly in dumbbell shape and spherical shape The size is 2-6μm, and the specific surface area is 230-300m 2 / g Porous calcium carbonate crystal particles with nano-pyramid microstructure units with side lengths of 100-300nm regular triangl...

Embodiment 3

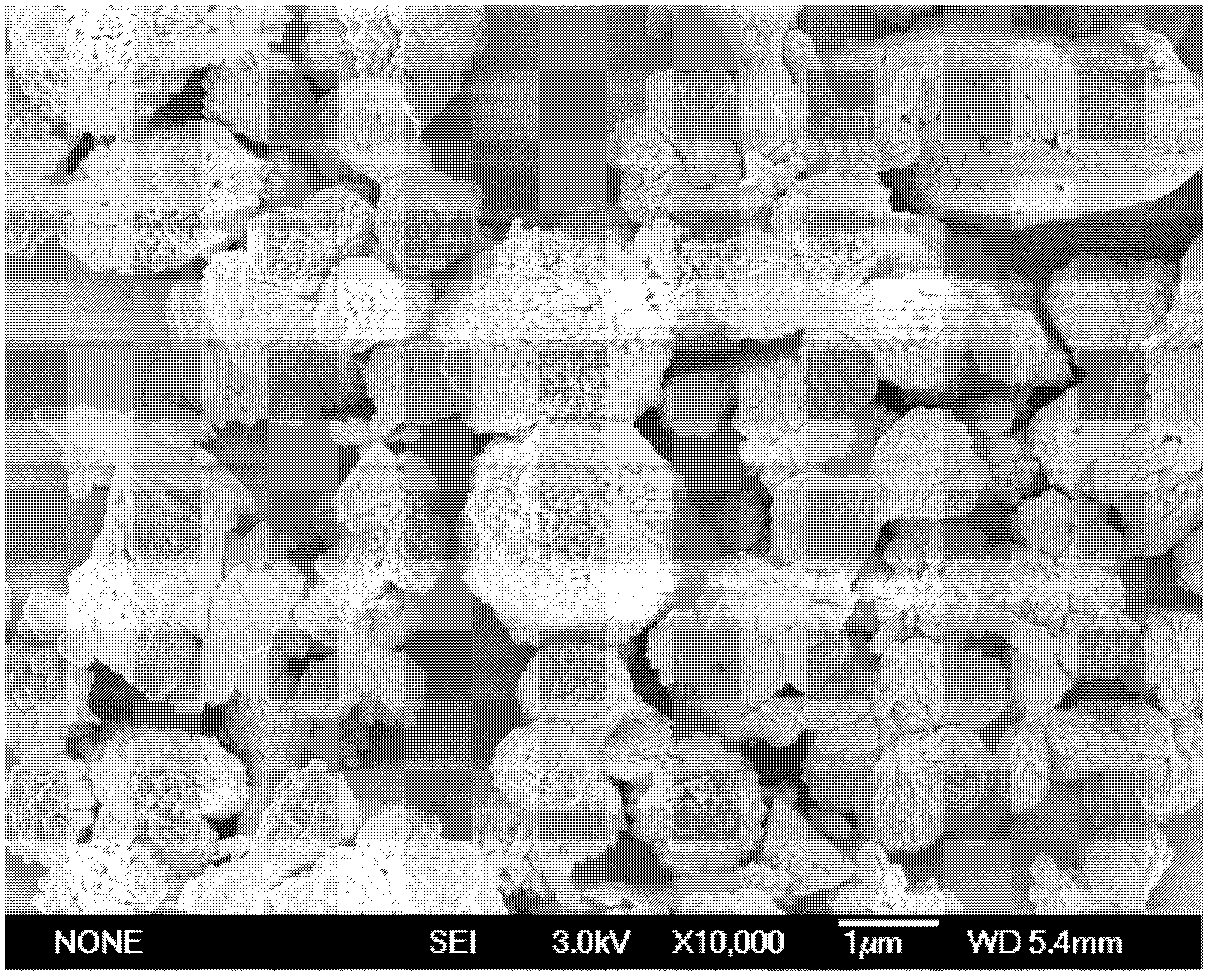

[0040] After cleaning the 1L glass beaker, prepare 900ml of a mixed aqueous solution containing 0.1g / L of polyaspartic acid and 0.001g / L of 2-aminoethanol, wherein the mole of the hydroxyl group in the mixed aqueous solution and the carboxyl group of polyaspartic acid The ratio is about 1:50; under stirring, adjust the pH value of the above-mentioned mixed aqueous solution to 13 with potassium hydroxide, inject 100 ml of 0.02 mol / L calcium nitrate aqueous solution, and continue to inject 10 ml of 0.2 mol / L potassium carbonate aqueous solution after stirring evenly; After the completion of the aging at room temperature for 70 hours, the solid product was separated and dried to obtain dumbbell-shaped and spherical particles with a particle size or length of 1.5-5 μm and a specific surface area of 110-160 m 2 / g Porous calcium carbonate crystal particles with nano-cone microstructure units with a side length of 200-500 μm regular triangle as the base.

[0041] The SEM photo of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com