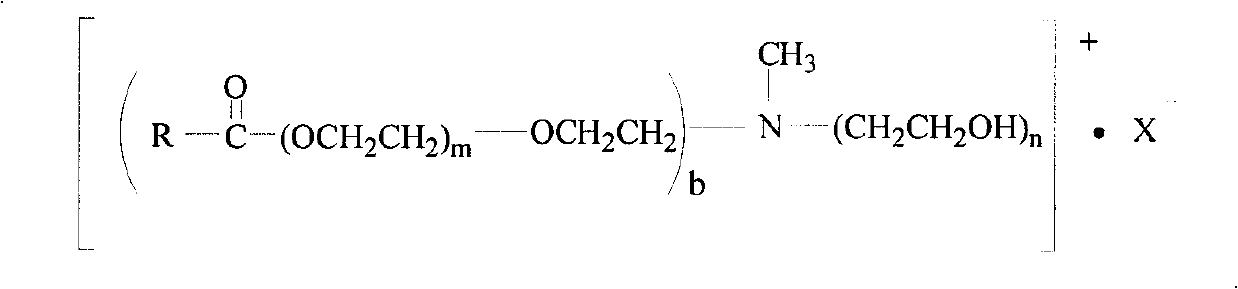

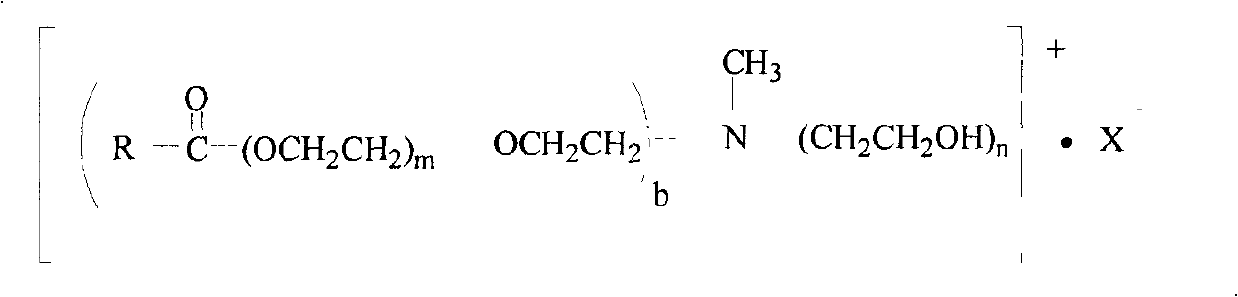

Ethoxylate ester quaternary ammonium salt and its preparation method

A technology of ethoxylated ester and quaternary ammonium salts, which is applied in the preparation of amino hydroxyl compounds, sulfuric acid esters, chemical instruments and methods, etc., and can solve the problem of reducing the overall use of ester quaternary ammonium salts for triesteramine quaternary ammonium salts There are no reports on the modification of ester group quaternary ammonium salt, and the use effect is poor, so as to improve the difficulty of compounding, improve the overall use effect, and the effect of high content of active substances in the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix 34.2g of MgO and 14g of diatomaceous earth evenly, add to 200mL of aqueous solution containing 11.5g of aluminum chloride, stir for 1hr, wash, dry, calcinate at 500°C for 1hr, grind, and sieve to obtain a composition of MgO with a composition of 65wt%. , Alumina is 8.4wt%, and diatomaceous earth is 26.6wt% Mg-Al ester-based insertion ethoxylation catalyst.

[0031] Take by weighing 284g stearic acid and join in the four-necked flask of 500mL, under N 2 Stir and heat up to 80°C under protected conditions. After they are completely melted, add 1.8g of phosphorous acid and 75g of triethanolamine, and heat up to 180°C. After 6 hours of reaction, the acid value of the product is measured to be 3mgKOH / g, and the reaction is terminated to obtain ester amine.

[0032] Add 0.4g of the above-mentioned ester group-inserted ethoxylation catalyst to the ester amine, put it into a 1L autoclave under stirring, start stirring, N 2 Replace the air, raise the temperature to 120°C, ...

Embodiment 2

[0035] Add 300mL of an aqueous solution containing 85g of aluminum nitrate and 27g of diatomaceous earth dropwise into 150mL of a dispersion containing 58g of CaO, and stir at room temperature for 1 hr to obtain a mixed catalyst slurry, which is removed by strong basic anion exchange resin. NO 3 - , after the ion exchange is completed, the catalyst is separated from the ion resin, dried, calcined at 500° C. for 1 hr, ground and sieved to obtain a Ca- Al ester-based intercalated ethoxylation catalyst.

[0036] Take by weighing 200g lauric acid and join in the four-neck flask of 500mL, under N 2 Stir and heat up to 90°C under protected conditions. After they are all melted, add 0.3g p-toluenesulfonic acid and 75g triethanolamine, heat up to 160°C, and react for 5 hours. The acid value of the product is 2.5mgKOH / g, stop reaction to give esteramine.

[0037] Add 1.6g of the above-mentioned ester group-inserted ethoxylation catalyst into the ester amine, put it into a 1L autocl...

Embodiment 3

[0040] Mix 20g of MgO powder with 9g of 4A zeolite, add to 500mL aqueous solution containing 1.9% gallium nitrate, stir vigorously for 1hr, dry at 110°C for 2hr, calcinate at 500°C for 1hr, grind and sieve to obtain MgO ester group containing gallium ions Plug-in ethoxylation catalyst. A gallium-ion-containing MgO ester-based insertion ethoxylation catalyst with a composition of 61.6 wt% of magnesium oxide, 10.7 wt% of gallium oxide and 27.7 wt% of 4A zeolite was obtained.

[0041] Take by weighing 256g palmitic acid and join in the four-neck flask of 500mL, under N 2 Stir and heat up to 60°C under protected conditions. After they are all melted, add 0.7g p-toluenesulfonic acid and 75g triethanolamine, heat up to 200°C, and react for 7 hours. The acid value of the product is 2.8mgKOH / g, stop reaction to give esteramine.

[0042] Add 3.8g of the above-mentioned ester group-inserted ethoxylation catalyst into the ester amine, put it into a 1L autoclave under stirring, start st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com