Novel chinlon cord thread oil agent and preparation method thereof

A technology for nylon cords and cords, which is applied in fiber types, textiles and papermaking, and fiber treatment, and can solve problems such as poor adhesion between cord fabrics and tires, poor compatibility between oil and latex, and low degree of tarring. Achieve excellent adhesion performance, improve soft performance, and low waste silk rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

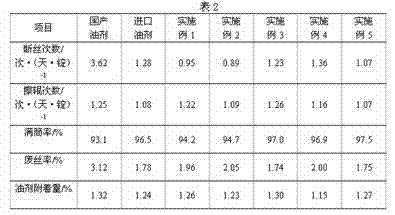

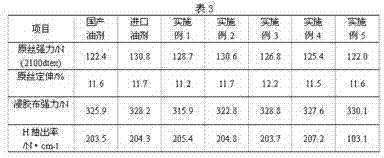

Examples

Embodiment 1

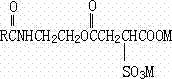

[0043] A kind of novel nylon cord finish of the present embodiment, described cord finish composition is made up of the following components by weight percentage:

[0044] (a) Triolein 18;

[0045] (b) methyl-terminated butanol-based EO / PO random addition polyether (EO / PO=25 / 75% (weight), V=2000) 42;

[0046] (c) lauryl alcohol-based EO / PO block addition polyether (EO / PO=50 / 50% (weight), MV=5000) 25;

[0047] (d) Sodium Cocoyl Monoethanolamide Sulfate 6;

[0048] (e) dodecylamine 8EO 3; castor oil polyoxyethylene ether (20EO) 5;

[0049] (f) Simethicone 0.8,

[0050] Ethanol 0.3.

[0051] The preparation method of a kind of novel nylon cord oil agent of the present embodiment comprises the following steps: pumping the above-mentioned component (c), component (d) and component (e) into the reactor, start stirring, and heat up to 50 ~60°C, stir evenly, then pump component (a) and component (b) into the reaction kettle, keep the temperature at around 50°C, stir for 40min, fi...

Embodiment 2

[0054] A kind of novel nylon cord finish of the present embodiment, described cord finish composition is made up of the following components by weight percentage:

[0055] (a) pentaerythritol tetralaurate 19;

[0056] (b) methyl-terminated lauryl alcohol EO / PO random addition polyether (EO / PO=40 / 60% (weight), MV=2500) 35;

[0057] (c) Octanol-based EO / PO block addition polyether (EO / PO=50 / 50% (weight), MV=8000) 15, butanol-based EO / PO random addition polyether (EO / PO =40 / 60% (weight), MV=10000) 15;

[0058] (d) Sodium Lauric Monoethanolamide Sulfosuccinate 4.5;

[0059] (e) octadecylamine 10EO 2,

[0060] S-80 3,

[0061] Isomerized tridecyl alcohol polyoxyethylene ether (8EO) 5;

[0062] (f) Simethicone 1.0,

[0063] Oleic acid 0.5.

[0064] The preparation method of a kind of novel nylon cord oil agent of the present embodiment comprises the following steps: pumping the above-mentioned component (c), component (d) and component (e) into the reactor, start stirring, an...

Embodiment 3

[0067] A kind of novel nylon cord finish of the present embodiment, described cord finish composition is made up of the following components by weight percentage:

[0068] (a) trimethylolpropane triisostearate 20;

[0069] (b) Butyl-terminated lauryl alcohol-based EO / PO random addition polyether (EO / PO=50 / 50% (weight), M V =5000) 20,

[0070] Methyl-terminated octanol block addition polyether (EO / PO=60 / 40% (weight), MV=2500) 25;

[0071] (c) cetyl alcohol EO / PO random addition polyether (EO / PO=50 / 50% (weight), MV=5000) 10,

[0072] Butanol-based EO / PO random addition polyether (EO / PO=35 / 65% (weight), MV=12000) 10;

[0073] (d) Isostearic acid monoethanolamide potassium sulfate 2, caprylic acid monoethanolamide sodium sulfate 2.5;

[0074] (e) octadecylamine 10EO 2,

[0075] S-80 3,

[0076] Isomerized tridecyl alcohol polyoxyethylene ether (8EO) 5;

[0077] (f) grafted silicone oil 0.5,

[0078] Oleic acid 0.5,

[0079] Ethanol 0.5.

[0080] The preparation metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com