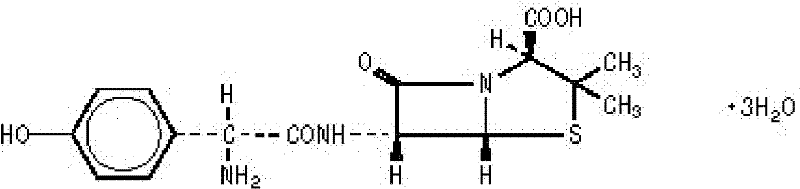

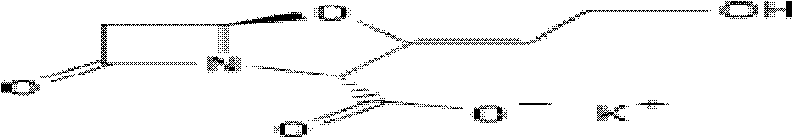

Amoxicillin or amoxicillin and clavulanate potassium instant chewable tablets for pet and preparation method for same

A technology of amoxicillin-clavulanate potassium and clavulanate potassium, which is applied in the field of amoxicillin or amoxicillin and clavulanate potassium instant chewable tablets for pets and its preparation, and can solve the problem that is not suitable for pet administration and other problems, to achieve the effect of convenient pet administration, overcoming small hardness, and simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

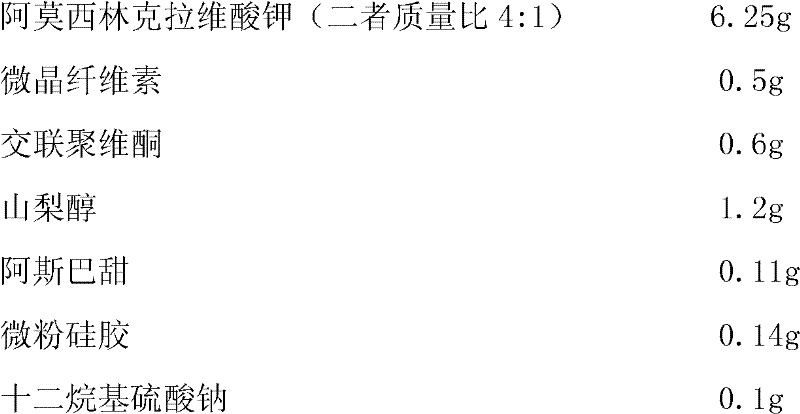

Embodiment 1

[0032]

[0033]

[0034] Preparation: ① Pass the raw material of potassium amoxicillin-clavulanate, sorbitol, aspartame, and sodium lauryl sulfate through a 100-mesh sieve, and grind mannitol and pass through a 50-mesh sieve; ②Weigh amoxicillin-clavulanic acid Potassium, microcrystalline cellulose, sorbitol and aspartame are mixed evenly, and granules are prepared with 10% povidone K30 absolute ethanol solution, passed through a 50-mesh sieve, and dried at 50°C. Sodium alkyl sulfate, mannitol, and crospovidone are mixed evenly, sprayed with essence and left for 30 minutes, and pressed into tablets, each tablet weighing 0.4g.

[0035] Tablet hardness and friability inspection: Prepare three batches of samples according to Example 1, take 6 tablets from each batch, put them into the small box of the tablet four-purpose tester for examining the friability, shake for 1 minute, take out and observe Its friability results. Results: The average hardness of the three batches of...

Embodiment 2

[0038]

[0039] Preparation: ① Grind the raw materials of amoxicillin, low-substituted hydroxypropyl cellulose, aspartame, and sodium lauryl sulfate, pass through a 100-mesh sieve, grind sorbitol, and mannitol and pass through a 50-mesh sieve; ②Weigh Take amoxicillin-clavulanate potassium, microcrystalline cellulose, low-substituted hydroxypropyl cellulose and aspartame and mix them evenly, then make granules with 10% povidone K30 absolute ethanol solution, pass through a 50-mesh sieve, 50 After granulation, add sodium lauryl sulfate, micropowder silica gel, and sorbitol, mix well, spray the essence and leave it for 30 minutes, and press into tablets. Each tablet weighs 0.4g.

[0040] According to the method in Example 1, the average hardness of the three batches of samples in this example is respectively: 33.8Kg, 33.0Kg, and 34.1Kg; there are no fragments or cracks.

[0041] According to the method in Example 1, the average disintegration time of the three batches of samp...

Embodiment 3

[0043]

[0044] Preparation: ① Pass amoxicillin-clavulanate potassium raw materials, crospovidone, low-substituted hydroxypropyl cellulose, aspartame through a 100-mesh sieve, grind sorbitol and pass through a 100-mesh sieve; Potassium moxicillin clavulanate, crospovidone, sorbitol and aspartame are evenly mixed, then granulated with 10% povidone K30 absolute ethanol solution, passed through a 50-mesh sieve, dried at 50°C, and granulated, Add micropowder silica gel and low-substituted hydroxypropyl cellulose, mix well, spray the essence and leave it for 30 minutes, and press into tablets. Each tablet weighs 0.4g.

[0045] According to the method in Example 1, the average hardness of the three batches of samples in this example is respectively: 32.7Kg, 33.5Kg, and 32.3Kg; there are no fragments or lobes.

[0046] According to the method in Example 1, the average disintegration time of the three batches of samples in this example is 49.3s, 48.7s, and 48.4s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com