Method for preparing composite calcium bilirubinate from ox gall

A technology for compounding bilirubin calcium and ox bile, which is applied in the field of manufacturing compound bilirubin calcium and intermediates from ox bile, which can solve the problems of complex process and low efficiency, improve product yield and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

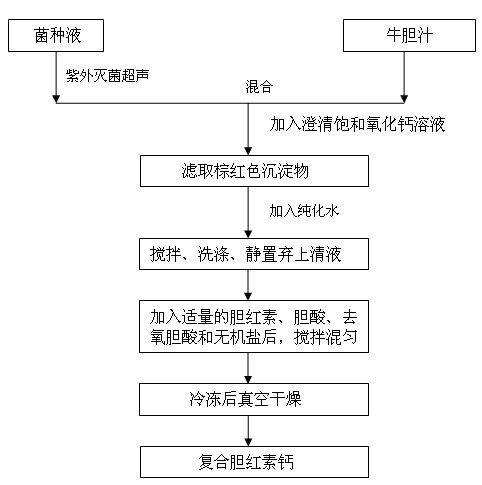

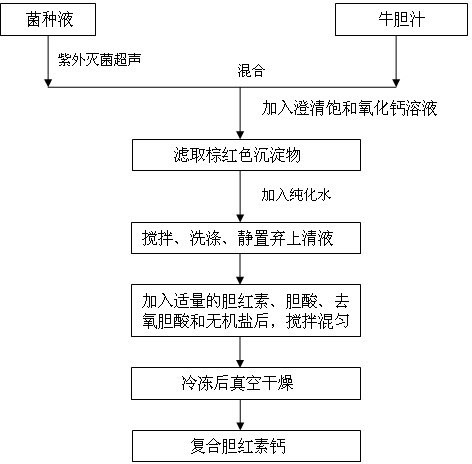

Method used

Image

Examples

Embodiment 1

[0015] (1) Adjust the content of taurine in natural ox bile to 3% (g / ml).

[0016] (2) The Escherichia coli liquid in the stable growth phase is subjected to ultraviolet sterilization treatment to kill the bacteria, and ultrasonic vibration is performed to rupture the bacteria, and 10000ml of ox bile is mixed with the strain treatment solution at a ratio of 1 to 1. Stir and keep warm at 30°C for 1.5 hours, adjust the pH value of the mixture to 5, stir and keep warm at 30°C for 1.5 hours, then add 11000ml of clarified saturated calcium oxide solution, stir well, and filter out the brown-red precipitate

[0017] (3) Add 350g bilirubin, 50g cholic acid, 25g deoxycholic acid, 3g zinc sulfate, and 3g magnesium sulfate to every 569g (dry weight) of the precipitate, stir and mix well for later use.

[0018] (4) Put the prepared compound bilirubin calcium into a low-temperature freezer, freeze at -5°C for 24 hours, then transfer it to a vacuum drying oven, vacuumize to 0.085Mpa, and ...

Embodiment 2

[0020] (1) Adjust the content of taurine in natural ox bile to 5% (g / ml).

[0021] (2) The Enterococcus bacterial liquid in the stable growth stage is subjected to ultraviolet sterilization treatment to kill the bacterial cells, and ultrasonic vibration is performed to rupture the bacterial cells, and 10000ml of ox bile is mixed with the strain treatment solution at a ratio of 2 to 1. Stir and keep warm at 40°C for 1 hour, adjust the pH value of the mixture to 4, stir and keep warm at 40°C for 1 hour, then add 30,000ml of clarified saturated calcium oxide solution, stir well, and filter out the brown-red precipitate

[0022] (3) Add 450g bilirubin, 100g cholic acid, 50g deoxycholic acid, 5g zinc sulfate, and 5g magnesium sulfate to every 390g (dry weight) of the precipitate, stir and mix well for later use.

[0023] (4) Put the prepared compound bilirubin calcium into a low-temperature freezer, freeze at -8°C for 20 hours, then transfer it to a vacuum drying oven, evacuate t...

Embodiment 3

[0025] (1) Adjust the content of taurine in natural ox bile to 7% (g / ml).

[0026] (2) Ultraviolet sterilizing treatment is carried out on the Proteus bacterial liquid in the stable growth phase to kill the bacterial cells, and ultrasonic vibration is performed to rupture the bacterial cells, and 10000ml of ox bile is mixed with the bacterial strain treatment solution at a ratio of 3 to 1. Stir and keep warm at 50°C for 0.5 hours, adjust the pH value of the mixture to 3, stir and keep warm at 50°C for 0.5 hours, then add 40000ml of clarified saturated calcium oxide solution, stir well, and filter out the brown-red precipitate

[0027] (3) Add 550g bilirubin, 150g cholic acid, 75g deoxycholic acid, 6g zinc sulfate, and 6g magnesium sulfate to every 213g (dry weight) of the precipitate, stir and mix well for later use.

[0028] (4) Put the prepared compound bilirubin calcium into a low-temperature freezer, freeze at -10°C for 16 hours, then transfer it to a vacuum drying oven,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com