Method for regulating and controlling silk graft copolymerization reaction on basis of hydrophobic and hydrophilic performance of free radicals

A hydrophilic and hydrophobic copolymerization technology, which is applied in textiles, papermaking, and fiber treatment, can solve the problems of unfavorable industrial production, complicated process, and large gap, and achieve the effects of convenient implementation, simple operation, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

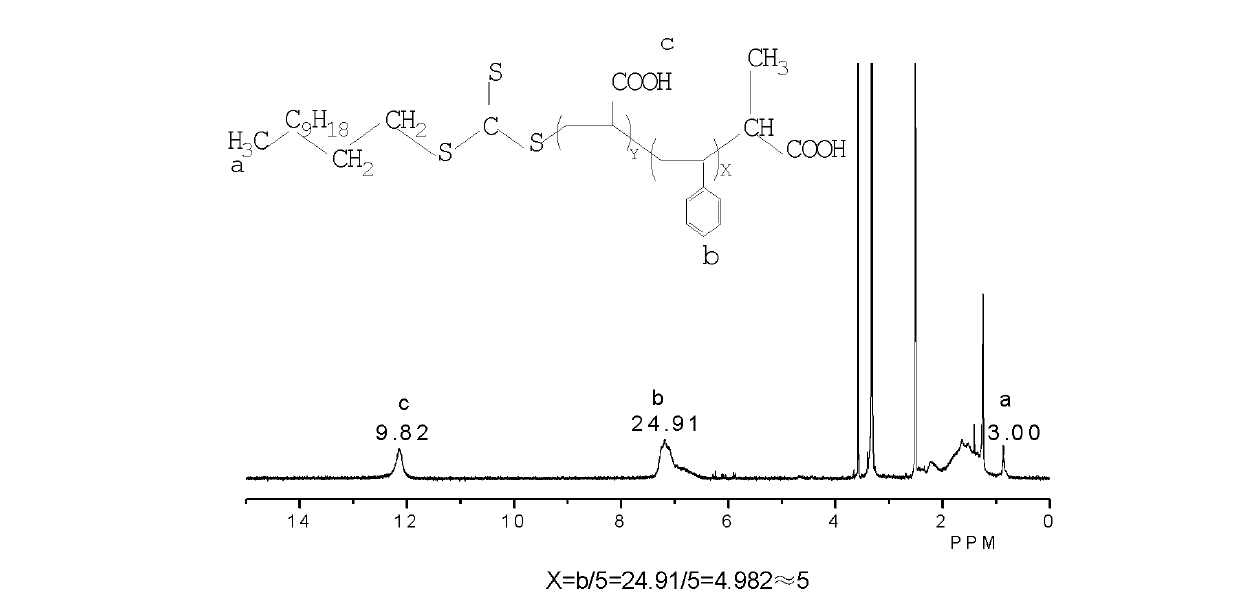

[0094] (1) Preparation of 2-(dodecyl trithiocarbonate group) propionic acid

[0095]Mix 10 grams of sodium hydroxide, 5.4 grams of tetrapropylammonium bromide and 10 grams of water uniformly at room temperature, add them to a 500 mL three-necked round-bottomed flask with a stirring bar and stir, and protect the reaction system with nitrogen gas. 60mL of dodecanethiol was added dropwise into a three-necked round-bottomed flask with a syringe, and the reaction was continued for 0.5 hours after the dropwise addition; During the dropwise addition, it can be observed that white flocs are generated and gradually increase. After the dropwise addition, the reaction is kept for 0.5 hours, and then ice bathed. After the temperature of the material in the reactor was completely lowered to 0°C, 15 mL of carbon disulfide was added dropwise into the flask with a syringe, and the reaction solution turned into a yellow turbid solution at this time. After keeping the reaction for 0.5 hour, 38...

Embodiment 2

[0102] (1) The preparation of 2-(dodecyl trithiocarbonate group) propionic acid is the same as in Example 1.

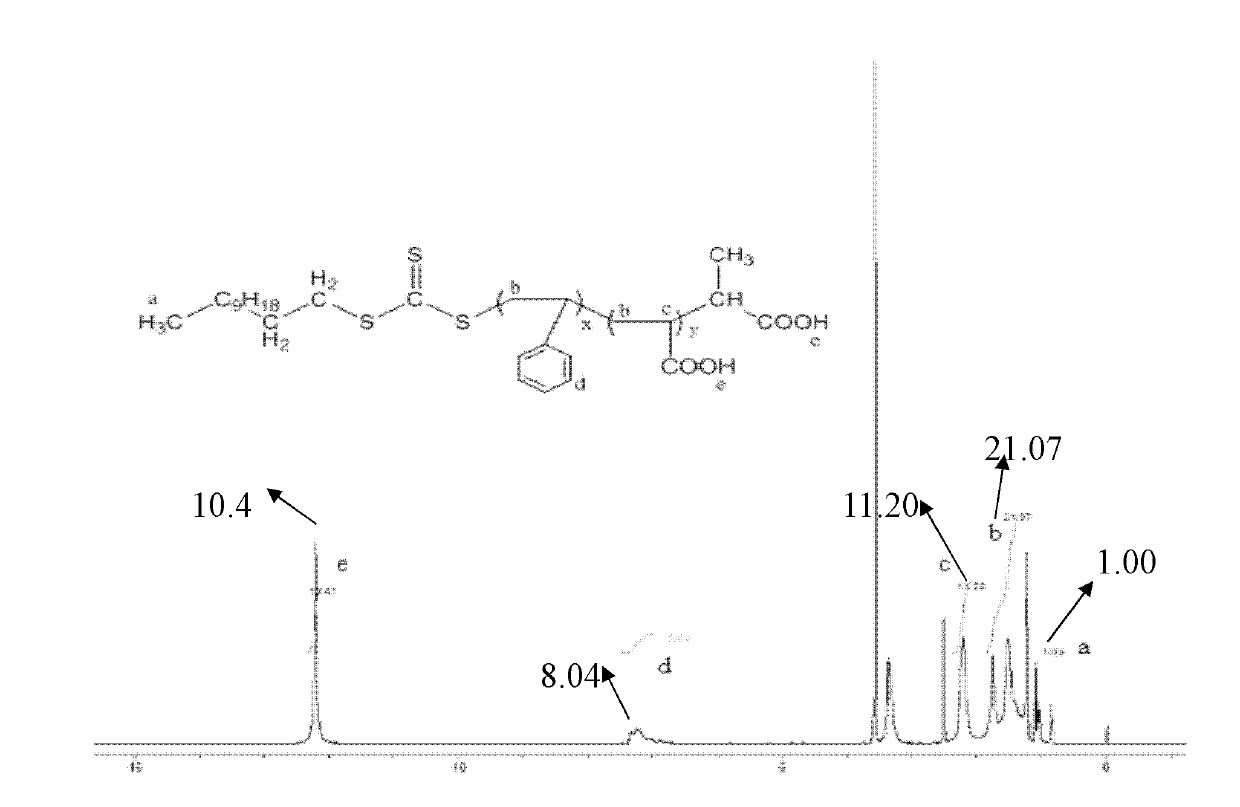

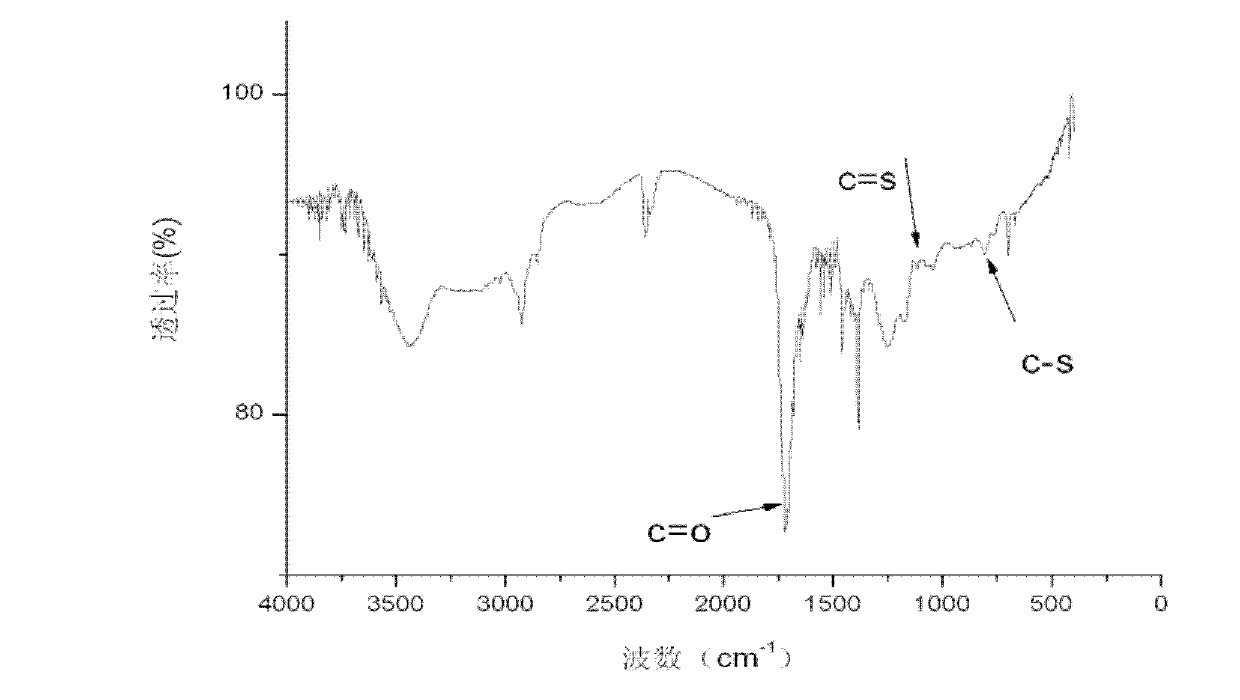

[0103] (2) preparation of the trithiocarbonate compound of formula V structural formula

[0104] Put the following reagents into a 500mL three-necked flask equipped with a reflux condenser, a nitrogen inlet, and a feed port: 28 grams of dioxane, 1.25 grams of yellow flaky crystals prepared in step (1), and 0.098 grams of azodicyanovaleric acid. grams and 3.34 grams of styrene. After passing high-purity (99.99%) nitrogen to the above device for 1 hour, immerse in a water bath at 80° C., and after 12 hours, an intermediate product was obtained; continue to add 18 grams of dioxane and 0.067 grams of azodicyanovaleric acid to the three-necked flask 1. 6.94 grams of acrylic acid, continued to react in a water bath at 80° C. for 8 hours, then lowered the temperature, stopped the reaction, and obtained a reaction product. The reaction product was poured into 200 mL of cycl...

Embodiment 3~20

[0109] Refer to Table 1 for the raw materials involved in Examples 3-20, the amount of raw materials used, and the reaction conditions of the copolymerization reaction. Weigh the dried refined silk and the trithiocarbonate compound, and put the two into a 50mL reaction bottle Add water, water-soluble monomers required for graft copolymerization and formic acid aqueous solution to the bottle, then place the reaction bottle in a oscillating water bath, and turn on the power of the water bath; when the temperature rises to the preset value of the copolymerization reaction When the temperature is 70°C-90°C, put an initiator into the reaction bottle to initiate the copolymerization reaction. After reacting at 70°C-90°C for 0.5h-2.0h, take out the primary silk grafted with water-soluble polymer and wash it with 100mL pure water Put into the 150mL washing bottle after washing, add soaping solution in bottle (soaping solution is the soda ash and 0.03% sodium hydrosulfite containing 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com