Ketotifen fumarate sustained-release capsules and preparation method thereof

A technology of ketotifen fumarate and sustained-release capsules, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, and the digestive system. It can solve problems such as poor safety, achieve stable drug release, simple process, and blood drug Concentration stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of ketotifen fumarate sustained-release capsule of the present invention comprises the steps:

[0032] 1) preparing a pill core containing medicine;

[0033] 2) package slow-release layer;

[0034] 3) aging;

[0035] 4) Make capsules.

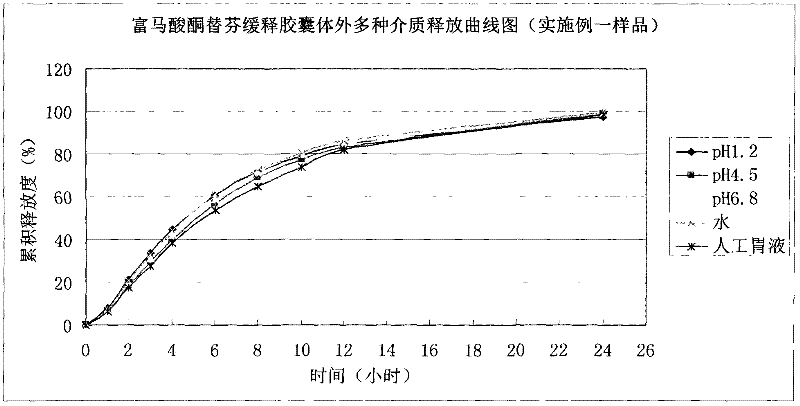

Embodiment 1

[0037] 1. Preparation of drug-containing pill core:

[0038]

[0039] making process:

[0040] Mix ketotifen fumarate and microcrystalline cellulose uniformly by increasing the method in equal amounts, add water to make a soft material, use extrusion-spheronization mechanism pellets, the particle size of the sieve plate is 0.8mm, and dry in an oven at 50°C. Sieve, select 20-40 mesh pill-containing cores, and coat them.

[0041] 2. Package slow-release layer:

[0042]

[0043] Add the prescribed amount of Surelease into water, make it fully dispersed, stir for 45 minutes, place the pill core in a fluidized bed, adjust various process parameters to ensure a fluidized state, and increase the weight of the coating to 10%.

[0044] Process parameters of the fluidized bed: air intake: 20-30HZ, air intake temperature: 25-35°C, atomization pressure: 1.0bar, liquid spray speed: 2-4g / min.

[0045] 3. Curing: Curing in an oven at 50°C for 12 hours.

[0046] 4. Capsules are prep...

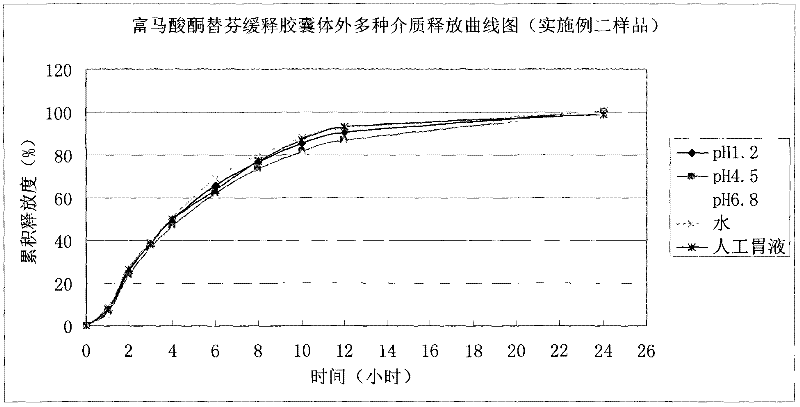

Embodiment 2

[0050] 1. Preparation of drug-containing pill core:

[0051]

[0052] making process:

[0053] Mix ketotifen fumarate, lactose, and microcrystalline cellulose evenly by increasing the amount in equal amounts, add water to make a soft material, use extrusion-spheronization mechanism pellets, the particle size of the sieve plate is 0.8mm, and bake in a 50°C oven Drying, sieving, and selecting 20-40 mesh pill-containing cores for coating.

[0054] 2. Package slow-release layer:

[0055]

[0056] Add the prescribed amount of talc powder into the water and stir for 45 minutes, add Eudragit NE30D water dispersion to make it fully dispersed, continue stirring for 45 minutes, and set aside. The pill core containing the drug is placed in a fluidized bed, and various process parameters are adjusted to ensure a fluidized state, and the weight of the coating is increased to 5%.

[0057] Process parameters of the fluidized bed: air intake: 20-30HZ, air intake temperature: 25-35°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com