Preparation method of nano-sized gold/ titanium dioxide compound mesoporous microspheric photocatalyst

A titanium dioxide and photocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high semiconductor carrier recombination rate, absorption and utilization wavelength range narrow, scarce photocatalytic activity, etc., to achieve the effect of enhanced visible light catalytic activity, easy mass transfer, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

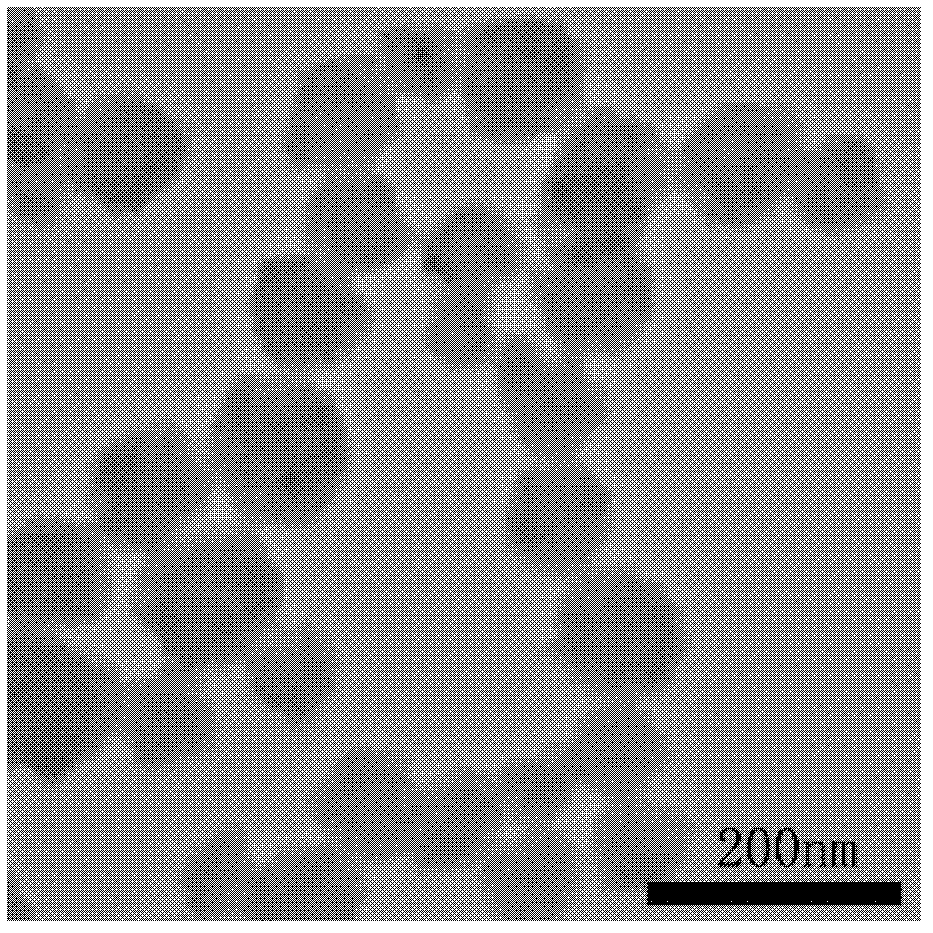

[0030] a. Using the existing solvothermal method to pre-synthesize monodisperse oil phase titanium dioxide nanocrystals. Dissolve 1 mL of tetrabutyl titanate in a mixed solution of 7 mL of oleic acid and 20 mL of cyclohexane, then add about 5 mL of triethylamine, and stir evenly to obtain a clear and transparent solution. Transfer this solution to a hydrothermal kettle with a polytetrafluoroethylene liner, tighten the lid of the kettle, heat treatment at a high temperature of 160°C for 24 hours, add ethanol solution to precipitate, and dissolve back with cyclohexane to obtain monodisperse oil phase titanium dioxide nanocrystals ;

[0031] b. Using the existing solvothermal method to pre-synthesize monodisperse oil-phase gold nanocrystals. Dissolve chloroauric acid in oleylamine to make a 20g / L chloroauric acid oleylamine solution, take the gold solution and toluene, mix and stir evenly at a ratio of 1:2, transfer it to a hydrothermal kettle, and conduct a hydrothermal treatme...

Embodiment 2

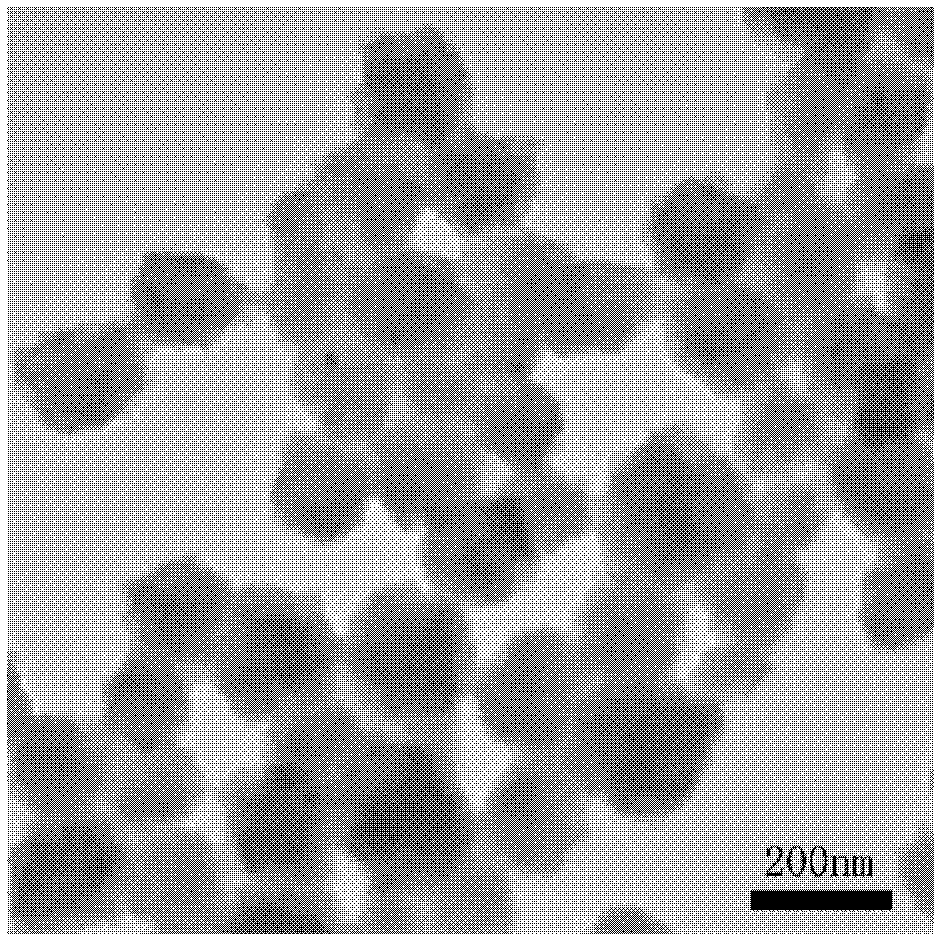

[0036] a. Using the existing solvothermal method to pre-synthesize monodisperse oil phase titanium dioxide nanocrystals. Dissolve 1 mL of tetrabutyl titanate in a mixed solution of 7 mL of oleic acid and 20 mL of cyclohexane, then add about 5 mL of triethylamine, and stir evenly to obtain a clear and transparent solution. Transfer this solution to a hydrothermal kettle with a polytetrafluoroethylene liner, tighten the lid of the kettle, conduct high-temperature hydrothermal treatment for 24 hours, add ethanol solution for precipitation, and dissolve back with cyclohexane to obtain monodisperse oil-phase titanium dioxide nanocrystals;

[0037] b. Using the existing solvothermal method to pre-synthesize monodisperse oil-phase gold nanocrystals. Dissolve chloroauric acid in oleylamine to make a 20 g / L chloroauric acid oleylamine solution, mix the gold solution and toluene at a ratio of 1:2 and stir evenly, then transfer it to a hydrothermal kettle, and conduct a low-temperature h...

Embodiment 3

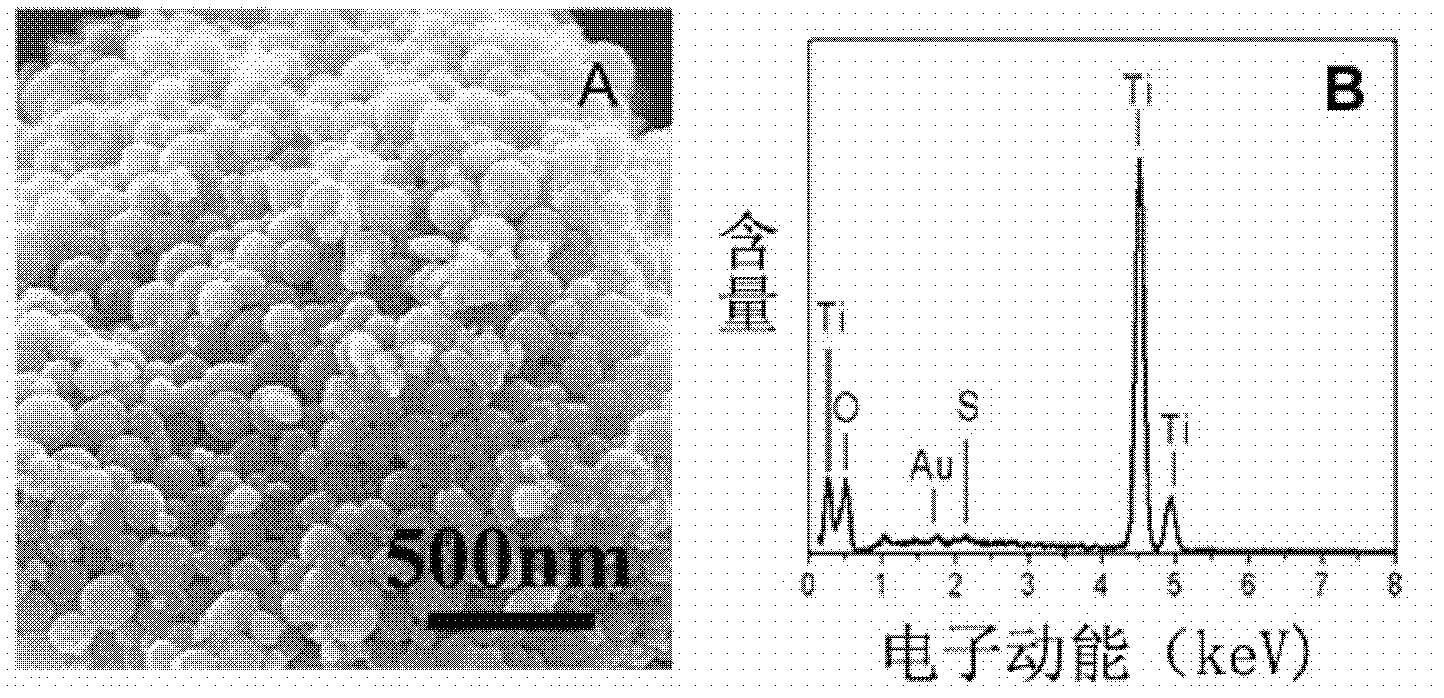

[0043] a. Using the existing solvothermal method to pre-synthesize monodisperse oil phase titanium dioxide nanocrystals. Dissolve 1 mL of tetrabutyl titanate in a mixed solution of 7 mL of oleic acid and 20 mL of cyclohexane, then add about 5 mL of triethylamine, and stir evenly to obtain a clear and transparent solution. Transfer this solution to a hydrothermal kettle with a polytetrafluoroethylene liner, tighten the lid of the kettle, conduct high-temperature hydrothermal treatment for 24 hours, add ethanol solution for precipitation, and dissolve back with cyclohexane to obtain monodisperse oil-phase titanium dioxide nanocrystals;

[0044] b. Using the existing solvothermal method to pre-synthesize monodisperse oil-phase gold nanocrystals. Dissolve chloroauric acid in oleylamine to make a 20 g / L chloroauric acid oleylamine solution, mix the gold solution and toluene at a ratio of 1:2 and stir evenly, then transfer it to a hydrothermal kettle, and conduct a low-temperature h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com