Method for degrading organic matters by photoelectrocatalysis

A technology of photoelectric catalysis and organic matter, which is applied to the application of graphene/titanium dioxide composite structure thin film electrodes in the field of photoelectric catalytic degradation, and the application of modified thin film electrode materials in the field of photoelectric catalytic degradation of organic matter, to improve conduction and the method is simple and easy to operate. , controllable and repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Graphite oxide / TiO 2 Preparation of complex:

[0031] Weigh 0.01g of purchased graphene oxide (Xianfeng Nano, Nanjing), add to 50ml of water, then add 1g of TiO 2 And 0.1g PEG (polyethylene glycol), ultrasonic 30min, finally get graphene oxide / TiO 2 Complex.

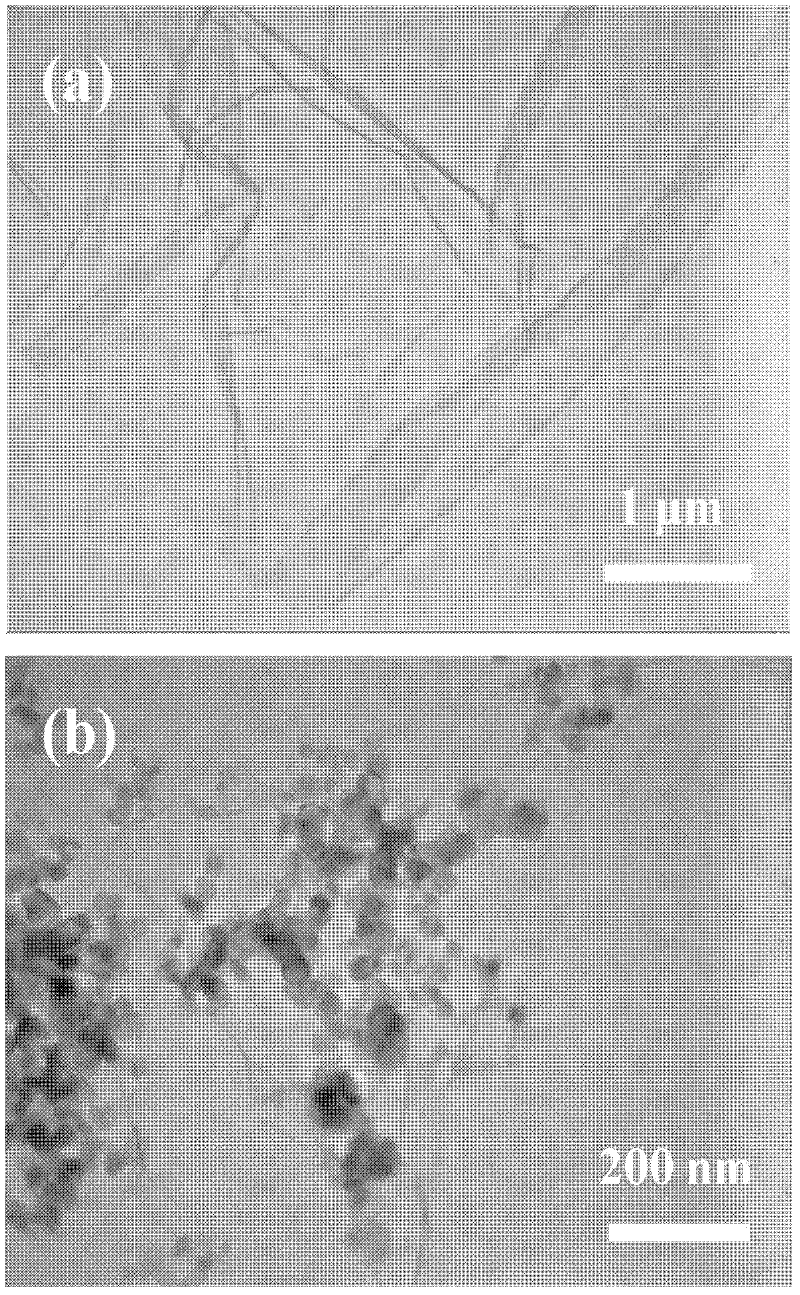

[0032] Such as figure 1 (a), it can be seen that the size of graphene oxide is on the order of microns, and the graphene oxide shown in the figure is a sheet-like structure with certain wrinkles.

[0033] Such as figure 1 (b), it can be seen that TiO 2 The diameter of the nanoparticles is about 20nm, and the TiO 2 Nanoparticles are well compounded with graphene oxide.

[0034] 2) Graphene / TiO 2 Film preparation:

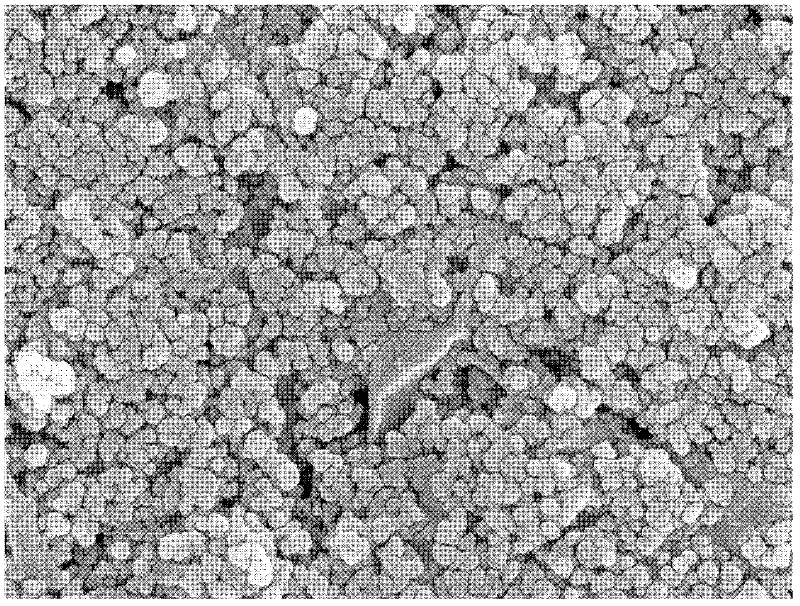

[0035] The resulting graphene oxide / TiO 2 Composite coated on conductive glass resulting in graphene oxide / TiO 2 film. After being dried at 80°C, it was reduced with hydrazine hydrate vapor at 60°C for 24 hours, and then the obtained sample was calcined at 400°C for 0.5 hours, and the obta...

Embodiment 2

[0040] 1) Photodegradation catalytic experimental device:

[0041] Thin film electrode, platinum wire and saturated calomel electrode were used as working electrode, counter electrode and reference electrode respectively. The electrolyte is 0.1M Na 2 SO 4 Aqueous solution, the applied bias is provided by DJS-292C potentiostat.

[0042] Such as Figure 4 , shown in the figure is the device diagram for photodegradation. Among them, (1) working electrode (film electrode); (2) reference electrode; (3) counter electrode; (4) rotor; (5) Na 2 SO 4 solution; (6) potentiostat; (7) light source; (8) magnetic stirrer.

[0043] 2) Establishment of adsorption / desorption equilibrium between dyes and thin film electrodes:

[0044] Graphene / TiO 2 Thin film electrodes were added with an initial concentration of 0.5×10 -5 M Rhodamine B dissolved in water (50ml), with a saturated calomel electrode as a reference electrode and Pt as a counter electrode. Then stir at room temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com