Anti-crack and anti-corrosion plasticizer composition and preparation method thereof

A technology of plasticizer and composition, applied in the field of anti-cracking and anti-corrosion plasticizer composition and its preparation field, can solve the problems of cumbersome construction process, inaccurate measurement, difficult to guarantee project quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Liquid standard products for preparing anti-crack and anti-corrosion plasticizer compositions:

[0044] Requirements for the performance of concrete, mortar, and clean slurry: the plasticizing rate should reach 25%, the bleeding rate should be less than 5%, the plastic retention performance of concrete should not be less than 150mm in 30 minutes, the compressive strength ratio should be greater than 180% in one day, and greater than 170% in three days. More than 150% in seven days, more than 140% in 28 days, and the initial and final setting time is greater than or equal to 60min; the shrinkage ratio is less than 50% in 1 day, less than 80% in 3 days, less than 90% in 7 days, and less than 100% in 28 days; impermeability: The concrete penetration height ratio is less than 20%, the mortar water permeability pressure ratio is greater than 400%, and the slurry is applied to the outside waterproof: the wet base surface bond strength is greater than 0.6MPa in 28 days, water r...

Embodiment 2

[0049] Embodiment 2 (taking each production 1000kg product as example)

[0050] The preparation of the liquid retarding type product of anti-cracking anti-corrosion plasticizer composition: add pure water 60kg in mixing tank, add liquid standard type product 880kg, start agitator, add sodium gluconate (plasticizer) 30kg , 20kg of sucrose (plasticizer), 10kg of tartaric acid (plasticizer), stirred for 30 minutes to obtain a liquid retarded product of the anti-cracking and anti-corrosion plasticizer composition.

[0051] Add 800kg of solid powder standard product in the dry powder material mixing tank, start the agitator, add sodium gluconate (plastic retainer) 100kg, sodium tripolyphosphate (plastic retainer) 60kg, sucrose (plastic retainer) 40kg, fully Stir well to obtain a solid powder retarded product of the anti-crack and anti-corrosion plasticizer composition.

Embodiment 3

[0052] Embodiment 3 (taking 1000kg product as example)

[0053] Preparation of high-efficiency products of anti-cracking and anti-corrosion plasticizer composition: in a dry mix mixer, add micro-expansion clinker powder calcium aluminate (carrier) 300kg, calcium oxide (carrier) 100kg, magnesium oxide (micro-expansion agent) 100kg, magnesium fluorosilicate (micro-expansion agent) 100kg, aluminum sulfate (micro-expansion agent) 100kg, calcium sulfate (micro-expansion agent) 100kg, cellulose fiber (fiber) 50kg, polypropylene fiber (fiber) 50kg, standard Type (or retarded type) solid powder 100kg, fully stirred for 30 minutes to obtain a high-efficiency (standard type or retarded type) product of the anti-cracking and anti-corrosion plasticizer composition.

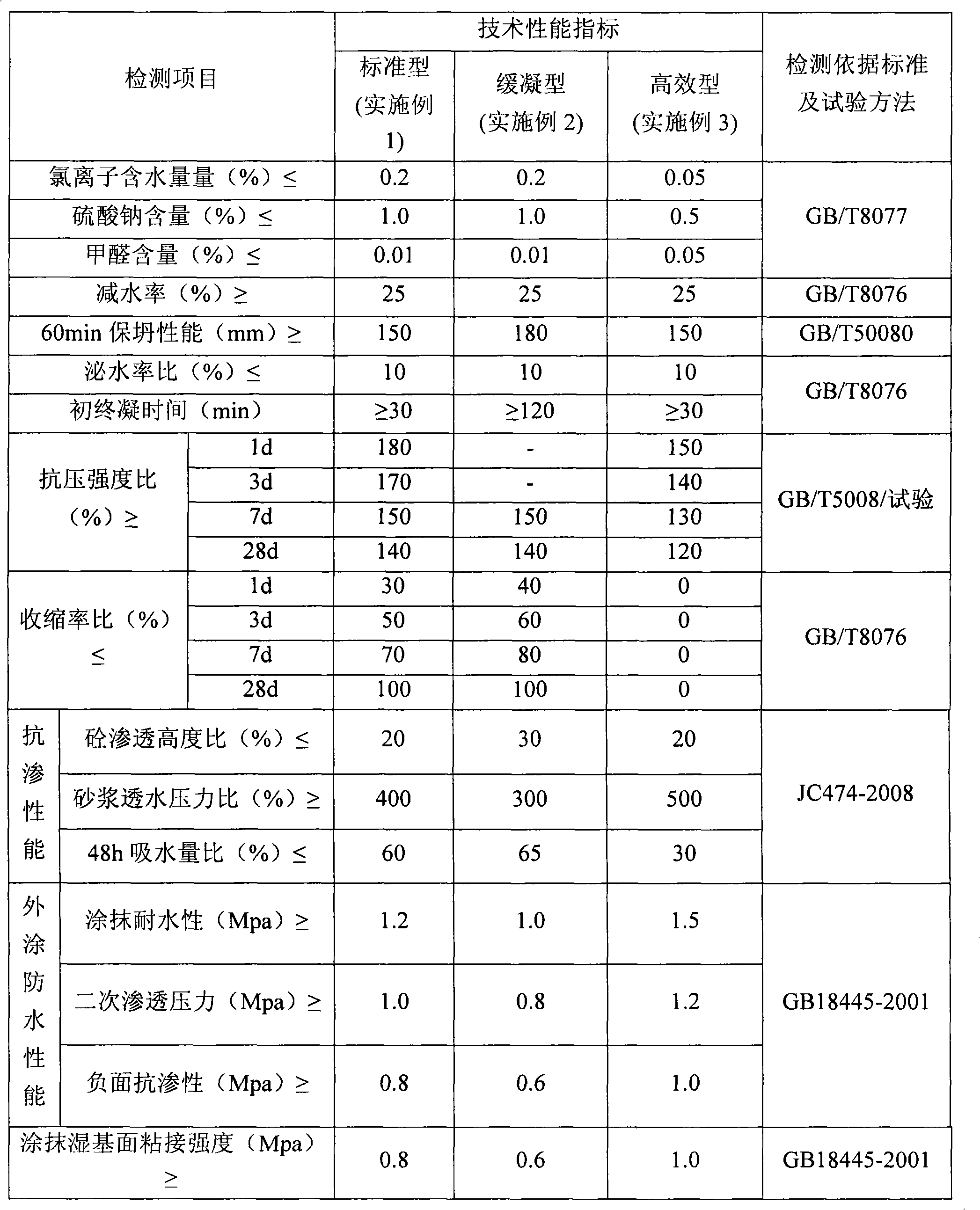

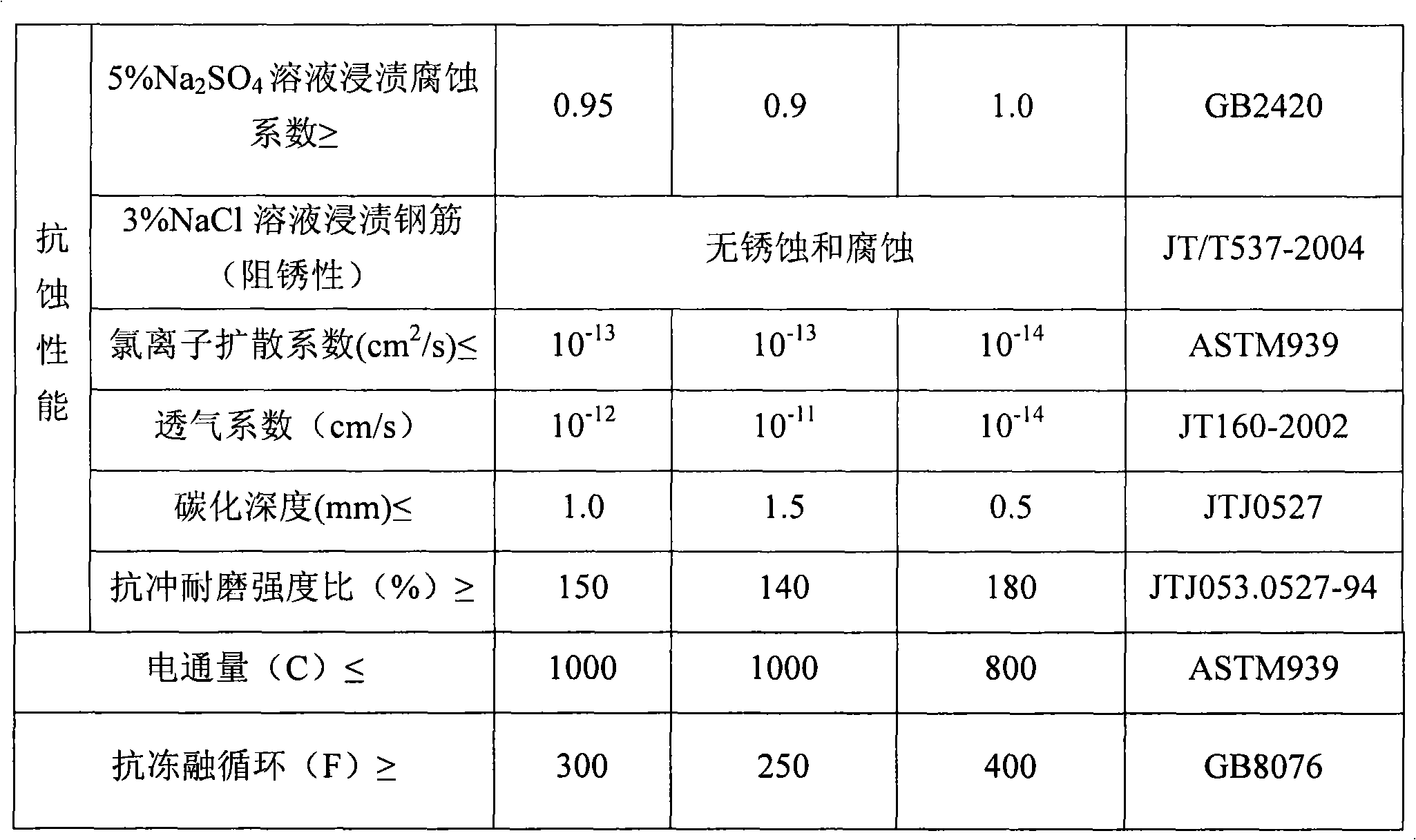

[0054]The detection technical performance indexes of the products of the anti-crack and anti-corrosion plasticizer composition prepared in Examples 1-3 are shown in Table 1.

[0055] Table 1

[0056]

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| electrical insulator | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com