Fermented feed additive, preparation method and application

A technology of fermented feed and additives, applied in application, animal feed, animal feed, etc., can solve the problems of difficult fermented feed technology, achieve the effects of reducing pollution and environmental protection treatment costs, alleviating competition between humans and animals, and promoting animal eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

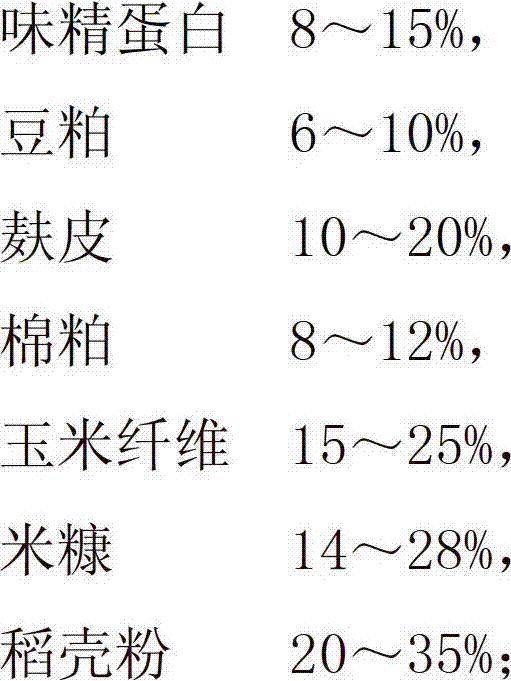

Method used

Image

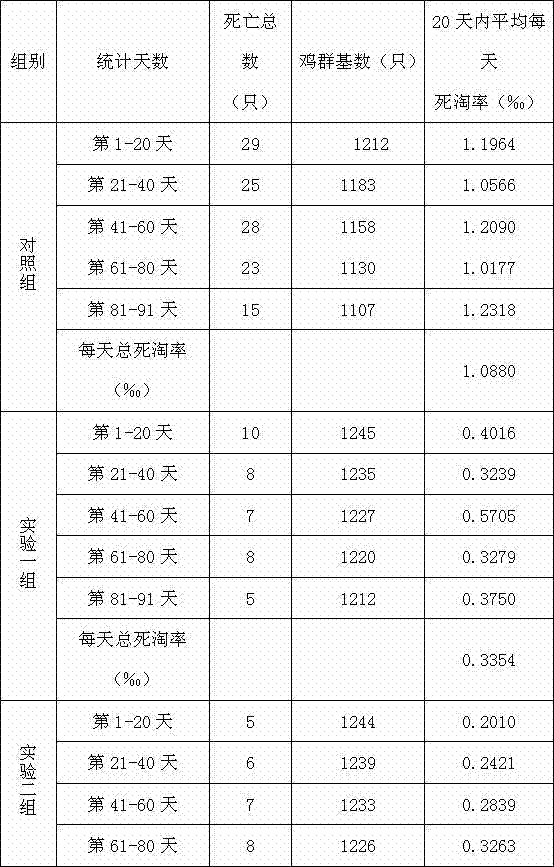

Examples

Embodiment 1

[0032] Under aseptic conditions, scrape a loop of the Lactobacillus acidophilus, Lactobacillus plantarum and Lactobacillus casei strains with an inoculating needle, and inoculate them into a petri dish containing a lactic acid bacteria activation medium. The lactic acid bacteria activate The medium is peptone 10g / l, meat extract 10g / l, yeast extract 5g / l, K 2 HPO 4 2g / l, triammonium citrate 2g / l, sodium acetate 5g / l, glucose 20g / l, Tween80 1mL / l, MgSO 4 ·7H 2 O 0.58g / l, MnSO 4 ·4H 2 O 0.25g / l, agar 20g / l and CaCO 3 After mixing 10g / l, the pH value is adjusted to 6.2 and sterilized at 121°C for 15 minutes; scrape a loop of the strain of Saccharomyces cerevisiae with an inoculating needle, and inoculate it into a culture dish containing yeast activation medium The yeast activation medium is obtained by mixing 200 g / l of potato into potato juice, 20 g / l glucose and 20 g / l agar; scraping the bacterial species of Bacillus subtilis and Bacillus licheniformis with an inoculation needle ...

Embodiment 2

[0035] Under aseptic conditions, scrape a loop of the Lactobacillus acidophilus, Lactobacillus plantarum and Lactobacillus casei strains with an inoculating needle, and inoculate them into a petri dish containing a lactic acid bacteria activation medium. The lactic acid bacteria activate The medium is peptone 12g / l, meat extract 12g / l, yeast extract 8g / l, K 2 HPO 4 4g / l, triammonium citrate 4g / l, sodium acetate 8g / l, glucose 25g / l, Tween80 2mL / l, MgSO 4 ·7H 2 O 1g / l, MnSO 4 ·4H 2 O 0.5g / l, agar 25g / l and CaCO 3 After mixing with 12g / l, adjust the pH to 6.4 and sterilize at 121°C for 20 minutes; scrape a loop of the strain of Saccharomyces cerevisiae with an inoculation needle, and inoculate it into a culture dish containing yeast activation medium The yeast activation medium is obtained by preparing 220g / l of potato into potato juice, 25g / l of glucose and 25g / l of agar; scraping the bacterial species of Bacillus subtilis and Bacillus licheniformis with an inoculation needle One ...

Embodiment 3

[0038] Under aseptic conditions, scrape a loop of the Lactobacillus acidophilus, Lactobacillus plantarum and Lactobacillus casei strains with an inoculating needle, and inoculate them into a petri dish containing a lactic acid bacteria activation medium. The lactic acid bacteria activate The medium is peptone 11g / l, meat extract 11g / l, yeast extract 6g / l, K 2 HPO 4 3g / l, triammonium citrate 3g / l, sodium acetate 6g / l, glucose 22g / l, Tween80 1.5mL / l, MgSO 4 ·7H 2 O 0.7g / l, MnSO 4 ·4H 2 O 0.3g / l, agar 22g / l and CaCO 3 After mixing 11g / l, the pH value is adjusted to 6.3 and sterilized at 121°C for 15 minutes; scrape a loop of the strain of Saccharomyces cerevisiae with an inoculating needle, and inoculate it into a culture dish containing a yeast activation medium The yeast activation medium is obtained by mixing 210 g / l of potato into potato juice, 22 g / l of glucose and 22 g / l of agar; scraping the bacterial species of Bacillus subtilis and Bacillus licheniformis with an inoculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com