Method for high-efficiency production of recombinant lipoxygenase by using Bacillus subtilis

A technology of lipoxygenase and Bacillus subtilis, which is applied in the field of high-efficiency production of recombinant lipoxygenase, can solve the problem that the complete removal of E. coli pyrogens cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Cloning of lipoxygenase gene from Anabaena sp. PCC 7120

[0032] Anabaena sp. PCC 7120 cells were collected by centrifugation, and the genomic DNA of Anabaena sp. was extracted with the Shanghai Sangon Genomic DNA Extraction Kit.

[0033] Two primers were designed according to the genome sequence published by NCBI:

[0034] Upstream primer: 5'GGAGTGTCTGGTGCC 3' (SEQ ID NO.12);

[0035] Downstream primer: 5'CTAAATGTTGATACTCATCAT3' (SEQ ID NO.13);

[0036]In a 50 μl system, the final concentration of upstream and downstream primers is 1 μM, the final concentration of dNTPs is 0.2 mM, 10 ng of Anabaena genomic DNA, and 2UPfu DNA polymerase. The amplification program was 94°C for 3min; 30×(94°C for 30s, 59°C for 50s, 72°C for 40s); 72°C for 10min. Agarose gel electrophoresis, gel cutting, recovery by Shanghai Sangon kit, connection of the recovered PCR product with TaKaRapMD19-T vector, transformation of E.coli DH5α, spreading on LB plates containing IPTG, X-ga...

Embodiment 2

[0037] Example 2 Construction of secreted expression vector pHBSR

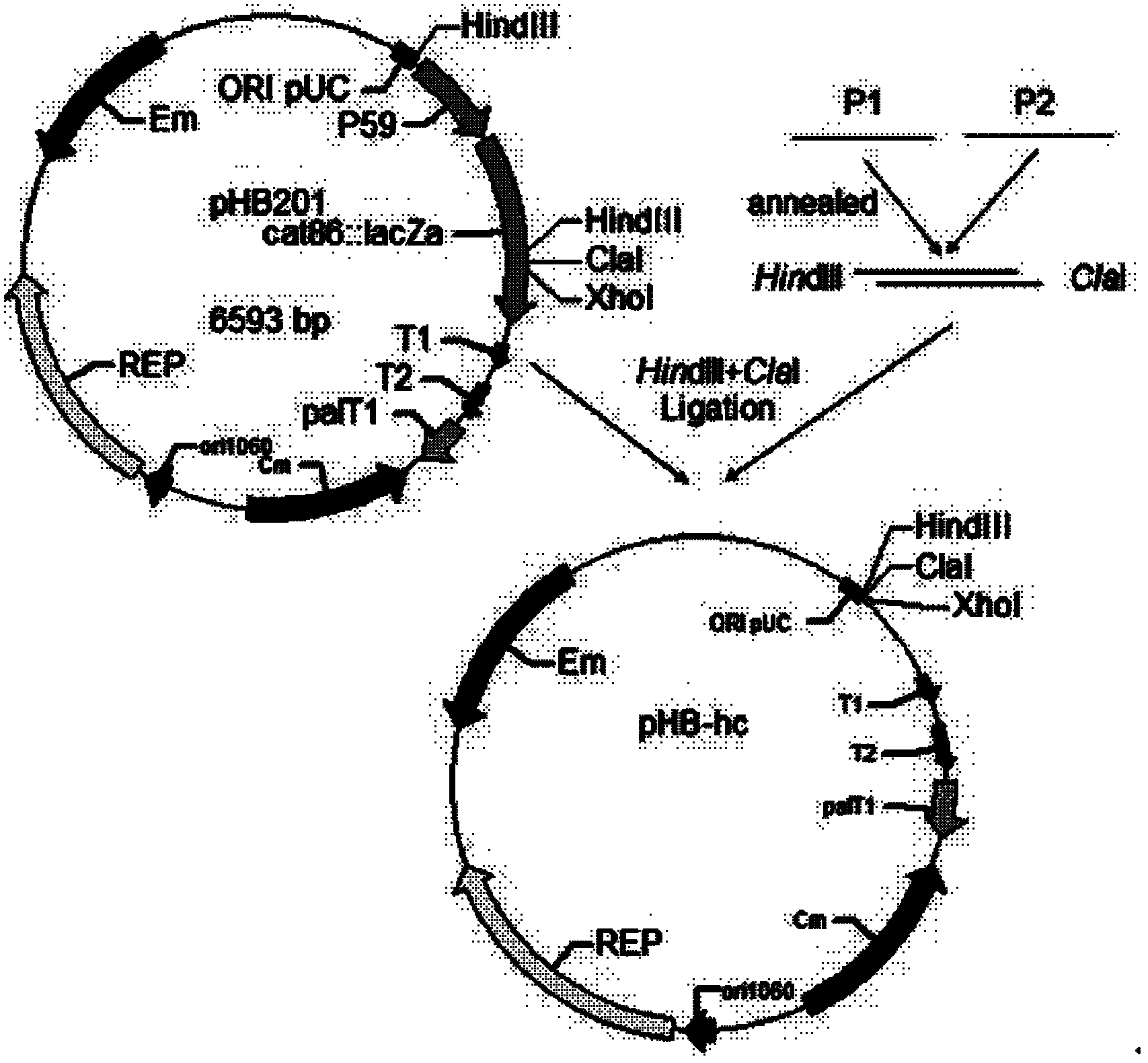

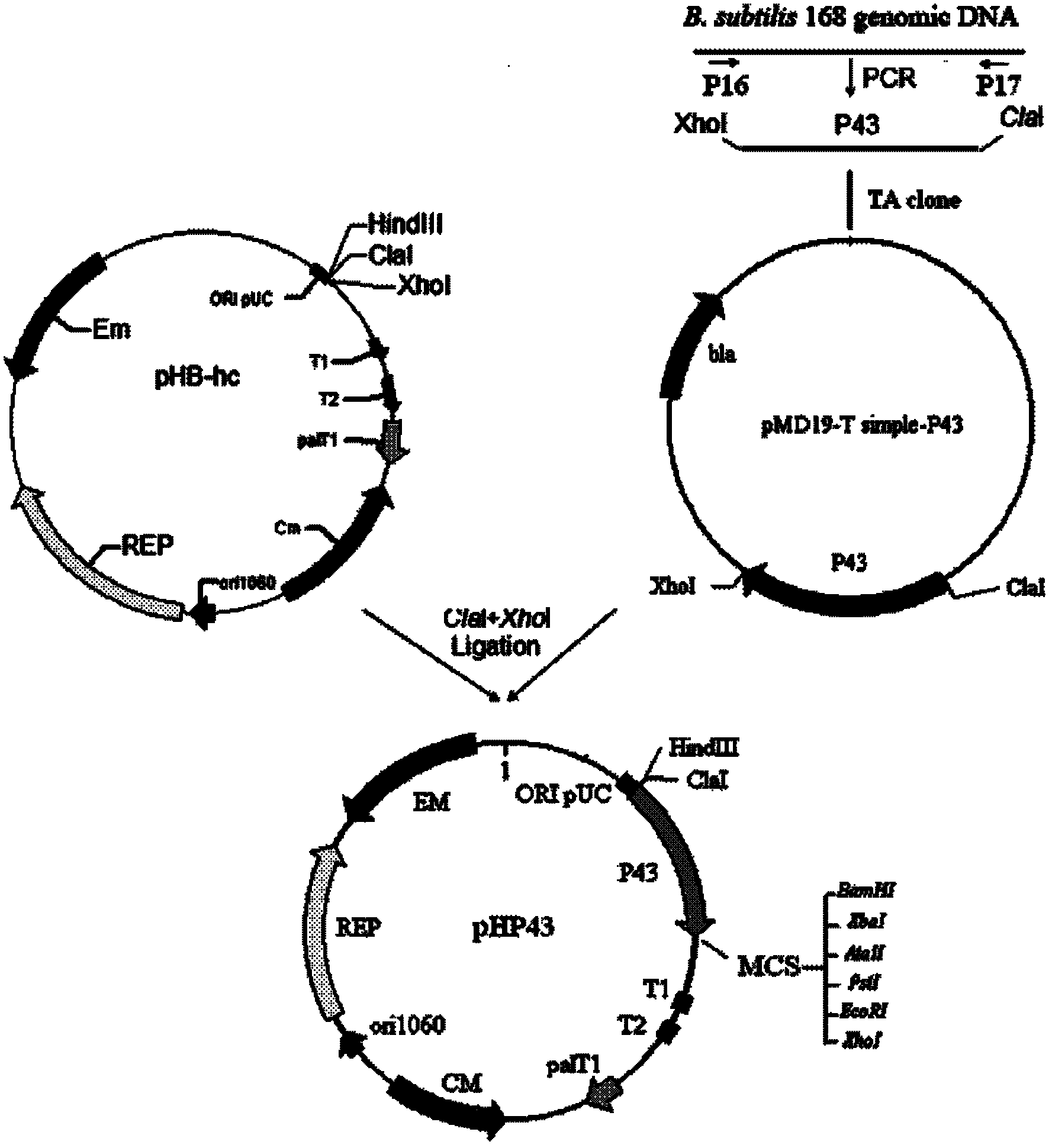

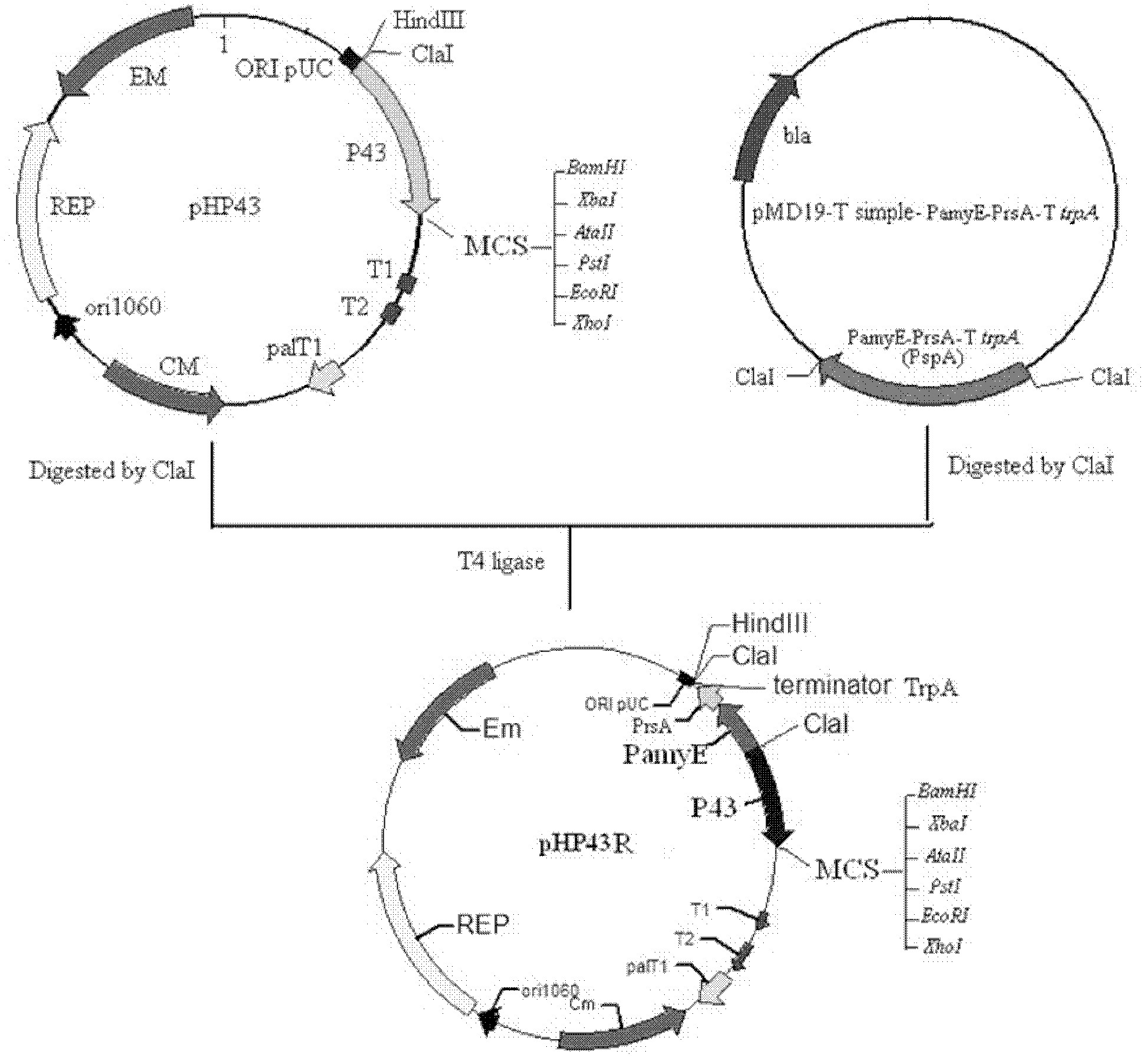

[0038] 2.1 The acquisition of carrier pHB-hc ( figure 1 )

[0039] In order to construct a Bacillus subtilis expression vector that can secrete foreign protein products, the Escherichia coli / Bacillus subtilis shuttle vector pHB201 was selected as the backbone, which is a stable cloning vector, and its backbone was derived from the Bacillus subtilis vector pTA1060. The multiple cloning site is located in the fusion gene cat86::lacZα, and because it is not suitable for expression, its promoter P59, cat86::lacZα region can be excised ( figure 1 ).

[0040] A pair of primers P1 (SEQ ID NO.2) and P2 (SEQ ID NO.3) are designed so that they can be paired to form double strands, and the two ends form sticky ends of ClaI and XhoI. The reaction system is as follows:

[0041] In a 200 µL PCR thin-walled tube add:

[0042]

[0043]

[0044] After mixing, denature in a water bath at 94°C for 2 minutes, cool natu...

Embodiment 3

[0061] Example 3 Construction of Prokaryotic Expression Vector of Anabaena sp.PCC 7120 Lipoxygenase Gene

[0062] According to the obtained lipoxygenase gene sequence, design two primers, the upstream primer plus the SacI recognition sequence, and the downstream primer plus the XhoI recognition sequence:

[0063] Upstream primer 5'-CGCGAGCTCGGAGTGTCTGGTGCC-3' (SEQ ID NO.14)

[0064] Downstream primer 5'-CCGCTCGAGCTAAATGTTGATACTCATCAT-3' (SEQ ID NO.15)

[0065] Add components according to the following PCR system to amplify the LOX gene:

[0066]

[0067] The PCR program is 94°C 2min; 30×(94°C 45s; 58°C 50s; 72°C 4min); 72°C 10min.

[0068] Purify the PCR product with Shanghai Sangon PCR Product Purification Kit, add SacI, XhoI double enzyme digestion, inactivation, ethanol precipitation, ddH 2 O was redissolved, ligated with an appropriate amount of vector pHBSR digested with the same restriction enzyme, and transformed into E. coli DH5α. Randomly pick a few colonies fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com