Hypereutectic aluminum-silicon alloy modifier and preparation method thereof

The technology of aluminum-silicon alloy and modifier is applied in the field of hypereutectic aluminum-silicon alloy modifier and its preparation, which can solve the problems of large energy consumption, limited application, high price, etc. The effect of simplifying the production process and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

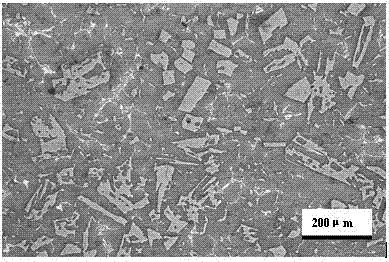

Embodiment 1

[0021] (1) Add about 200 mesh Al powder and CuP powder (containing 12% phosphorus) into the ball mill tank at a ratio of 1:1, then add stainless steel balls, and add the ball to material ratio at a ratio of 10:1, then vacuum ball mill Argon gas is introduced into the air inlet of the tank, and after the air is exhausted at a flow rate of 0.5L / min, the air outlet is tightened, and the air inlet is re-introduced for 2 minutes, and the air inlet is tightened at this time. Put it on a planetary ball mill with a rotating speed of 70r / min, change the direction every 30min, and mill for 3 hours. After cooling, open the ball mill tank, sieve it with a sieve, and pack it in a vacuum bag.

[0022] (2) After the mold is coated with release agent, air-dried, and the ball-milled powder is placed on the diameter Φ In the 30mm metal cylinder mold, after sufficient pre-compression, pressurize to 80KN, hold the pressure at 80KN for 5 minutes, change direction and perform double-sided pressing...

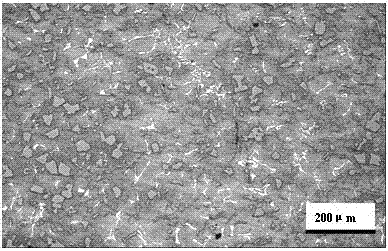

Embodiment 2

[0025] (1) Add 50% Al powder, 40% Cu powder and 10% P powder into the ball mill tank, the particle size of which is about 300 mesh, and then add steel balls according to the ball-to-material ratio of 20:1, and vacuum ball mill tank Put argon gas into the air inlet, and after the flow rate is 0.5L / min for about 3 minutes, tighten the air outlet, and then let it in for another 2 minutes, then tighten the air inlet. Put it on a planetary ball mill with a rotating speed of 90r / min, change the direction every 30min, and mill for 3 hours. After cooling, open the ball mill tank, sieve it with a sieve, and pack it in a vacuum bag.

[0026] (2) After applying the release agent, let it dry in air, and place the ball-milled powder on the diameter Φ In the 30mm metal cylinder mold, after sufficient pre-compression, pressurize to 70KN, hold the pressure at 70KN for 8 minutes, reverse the direction and perform double-sided pressing at 70KN pressure, slowly release the pressure, eject the m...

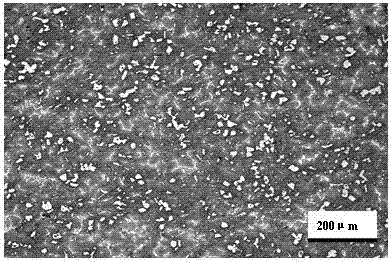

Embodiment 3

[0029] (1) Add 40% Al powder and 60% CuP powder (containing 8% phosphorus) into the ball mill tank with a particle size of about 200 mesh, then add stainless steel balls, and add steel balls at a ball-to-material ratio of 10:1. Put argon gas into the air inlet of the vacuum ball mill tank. After the flow rate is 0.5L / min for about 3 minutes, tighten the air outlet, and then let it in for another 2 minutes. At this time, tighten the air inlet. Put it on a planetary ball mill with a rotating speed of 100r / min, change the direction every 30min, and mill for 2 hours. After cooling, open the ball mill tank, sieve it with a sieve, and pack it in a vacuum bag.

[0030] (2) After applying the release agent, let it dry in air, and place the ball-milled powder on the diameter Φ In the 30mm metal cylinder mold, after sufficient pre-compression, pressurize to 70KN, hold the pressure at 70KN for 8 minutes, reverse the direction and perform double-sided pressing at 70KN pressure, slowly re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com