Antiseptic treatment method for surfaces of aluminum and aluminum alloy and products thereof

An aluminum alloy surface and anti-corrosion treatment technology, which is applied in thin material treatment, metal material coating process, liquid chemical plating, etc., can solve the problems of shortened product life, poor anti-corrosion performance, environmental pollution, etc., and achieve good anti-corrosion Corrosion performance, good anti-corrosion function, high chemical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The anticorrosion treatment method for aluminum and aluminum alloy surfaces in preferred embodiments of the present invention mainly includes the following steps:

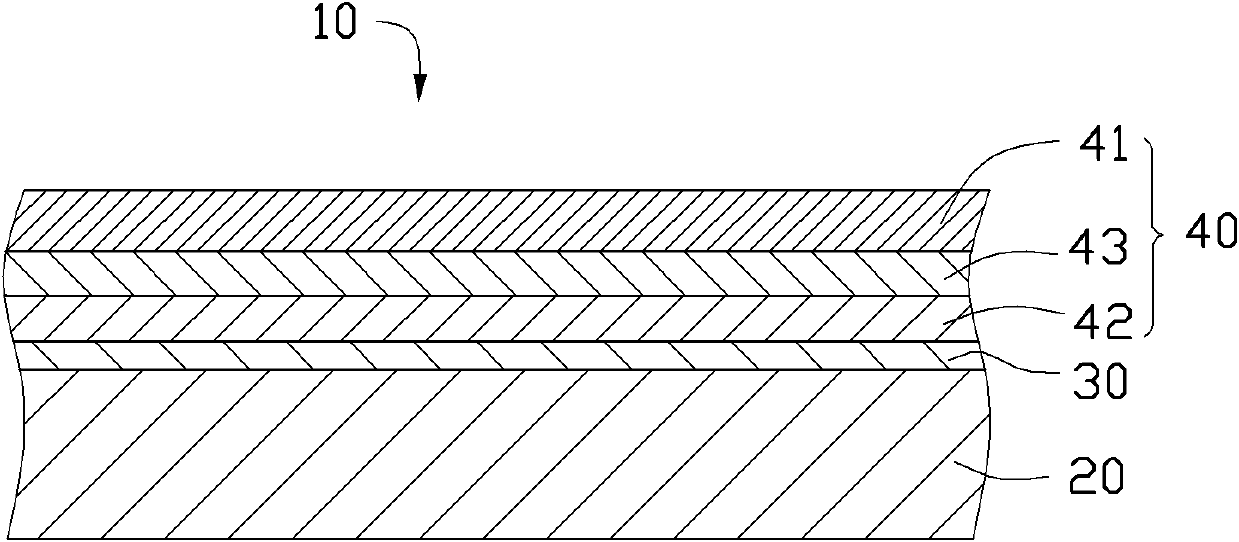

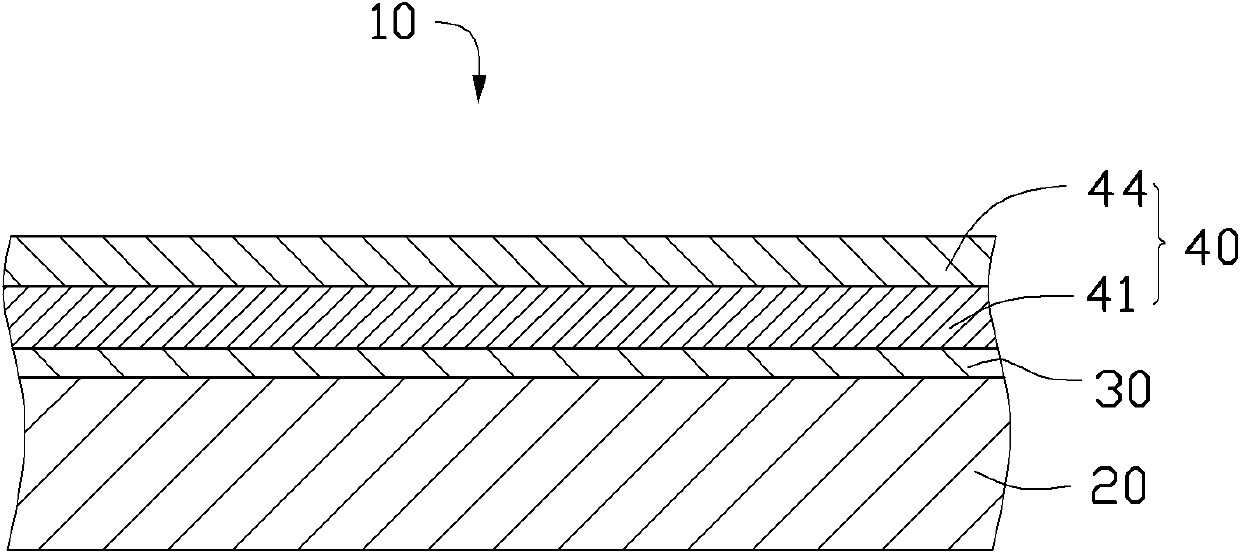

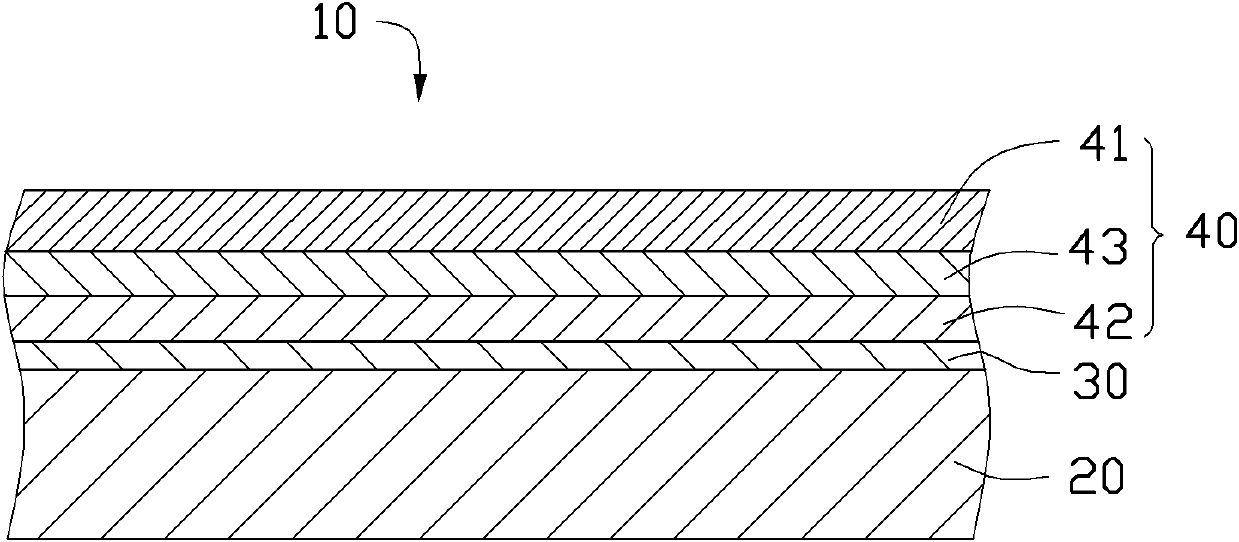

[0025] An aluminum base 20 is provided, and the material of the aluminum base can be pure aluminum or aluminum alloy.

[0026] The aluminum substrate 20 is chemically degreased. Chemical degreasing involves immersing the aluminum substrate 20 in a degreasing solution at 60-80°C for 30-60s. The degreasing solution used contains 25-30g / L sodium carbonate, 20-25g / L trisodium phosphate (Na 3 PO 4 12H 2 O) and the aqueous solution of 1-3g / L emulsifying agent, wherein said emulsifying agent can use the emulsifying agent of trade name OP-10, and its main component is the condensate of alkylphenol and oxirane.

[0027] A cerium salt-doped silane hybrid film 30 is prepared on the aluminum substrate 20 after chemical degreasing treatment. In this embodiment, the cerium salt-doped silane hybrid film 30 is prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com