Semi-insulating silicon carbide mono-crystal

A silicon carbide single crystal, semi-insulating technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of affecting the crystal quality, reducing the crystal electron mobility, affecting the performance of microwave devices, etc., to achieve resistivity. Stability, avoid process complexity and resistivity instability, effect of high crystalline quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

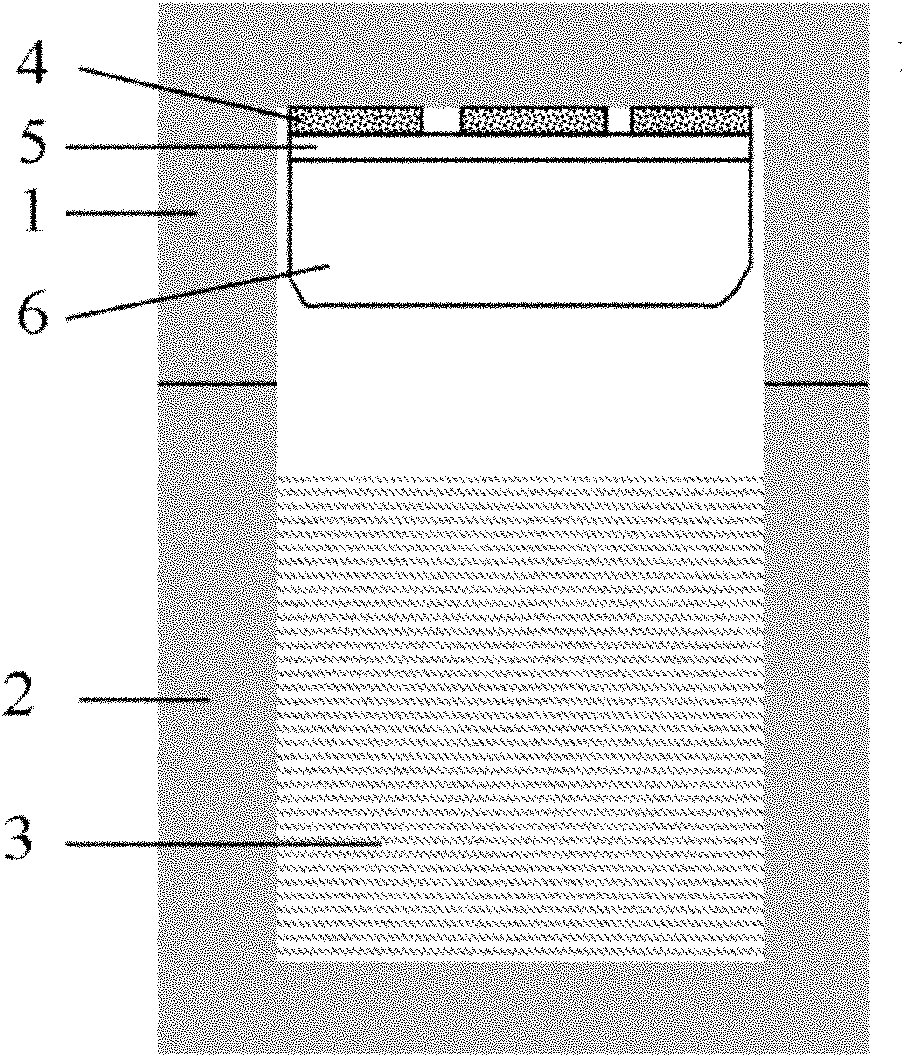

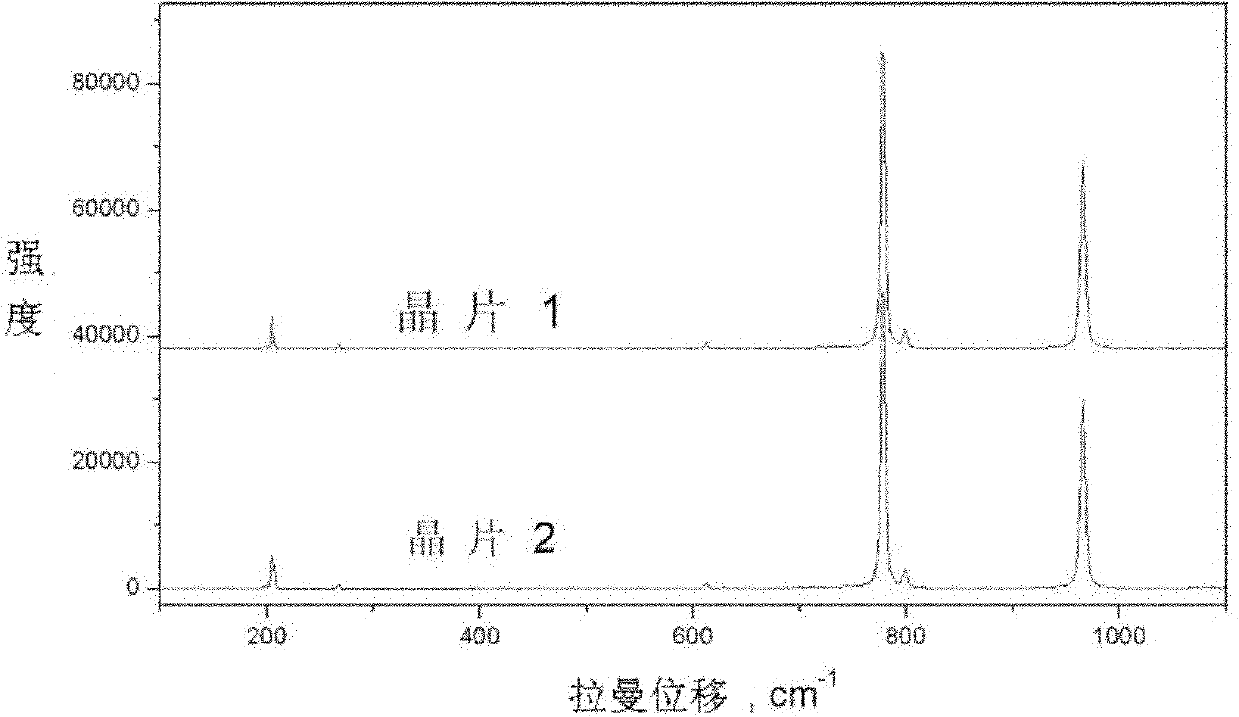

[0026] Crystal 1 is intentionally doped with a deep-level dopant (taking vanadium as an example), and its specific preparation method is as follows: add 200 mg of vanadium carbide powder (purity 99.999%) to 800 g of silicon carbide powder (purity 99.999%), Mix well and evenly with a ball mill and put it into the graphite crucible 2 as the raw material 3, cover the crucible cover 1 with the 4H-SiC seed crystal 5 bonded, and put it into the crystal growth furnace. The growth furnace is filled with argon gas, and the pressure is controlled at about 1500Pa. The temperature of the seed crystal is kept between 2000-2150°C, the temperature of the raw material is kept between 2250-2400°C, and the temperature gradient between the raw material and the seed crystal is kept between 150-300°C. The crystal growth rate is about 0.8 mm / h, and the growth ends after 15 hours, and is cooled to room temperature. As known to those of ordinary skill in the art, the introduction of point defects is...

Embodiment 2

[0036] This example adopts the same silicon carbide crystal preparation method as in Example 1. In this embodiment, the graphite crucible and heat preservation material are also purified, specifically, the graphite crucible and heat preservation material are heated to 2000° C. in an Ar atmosphere to allow impurities (such as aluminum and boron) to be fully volatilized. In this way, the influence of background impurities on crystal resistivity is minimized.

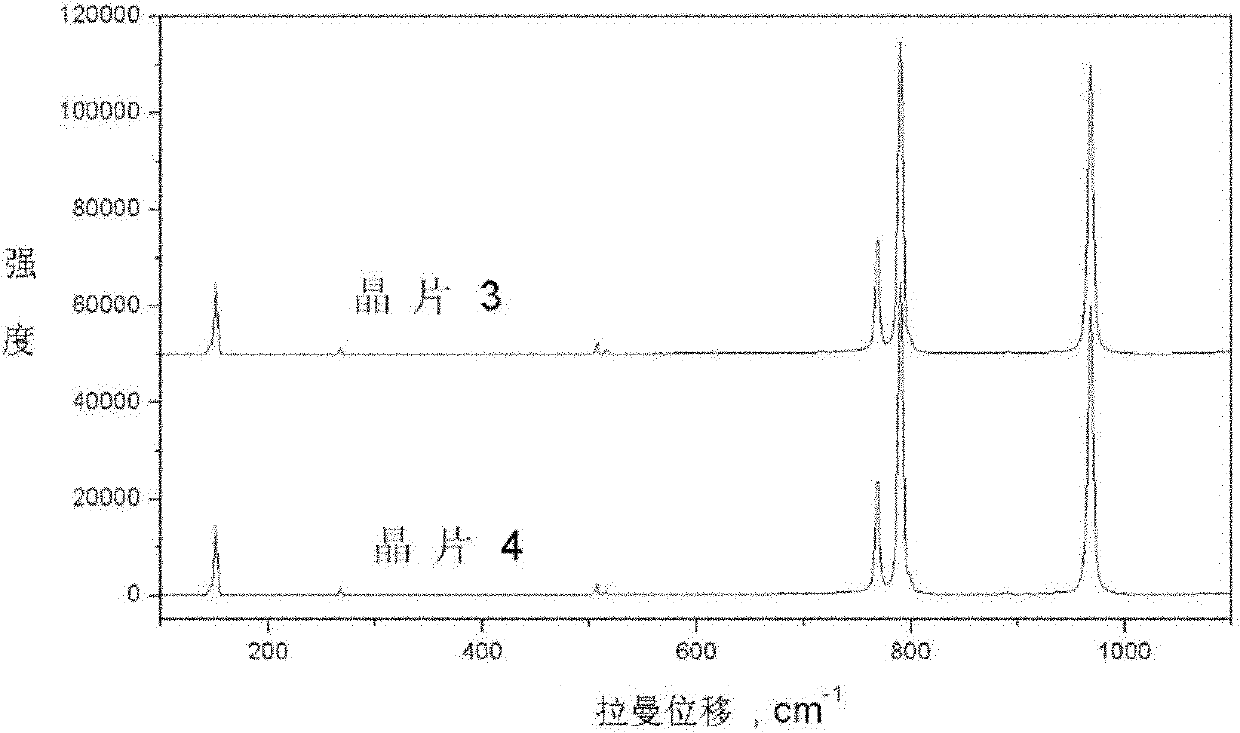

[0037] In this embodiment, crystal 3 selects vanadium as the deep level dopant. The specific preparation process is as follows: 250 mg of vanadium carbide powder (purity 99.999%) is added to 800 g of silicon carbide powder (purity 99.999%), fully mixed with a ball mill and then loaded into the graphite crucible 2 as raw material 3, and the lid is bonded A crucible lid 1 with a 6H-SiC seed crystal was removed and put into a crystal growth furnace. The growth furnace is filled with argon gas, and the pressure is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com