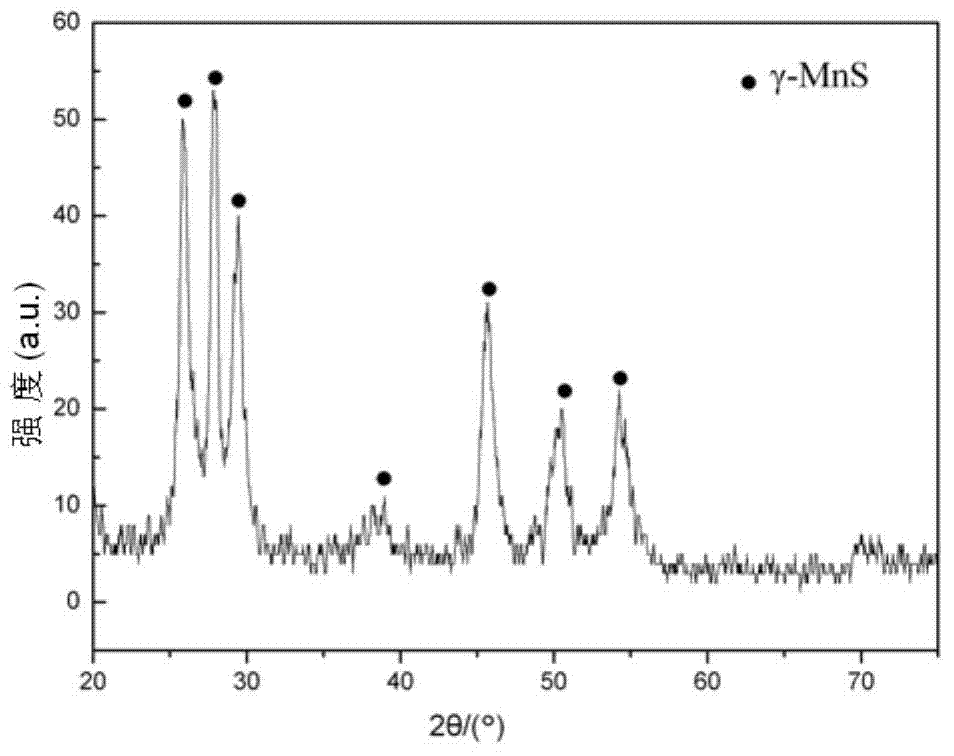

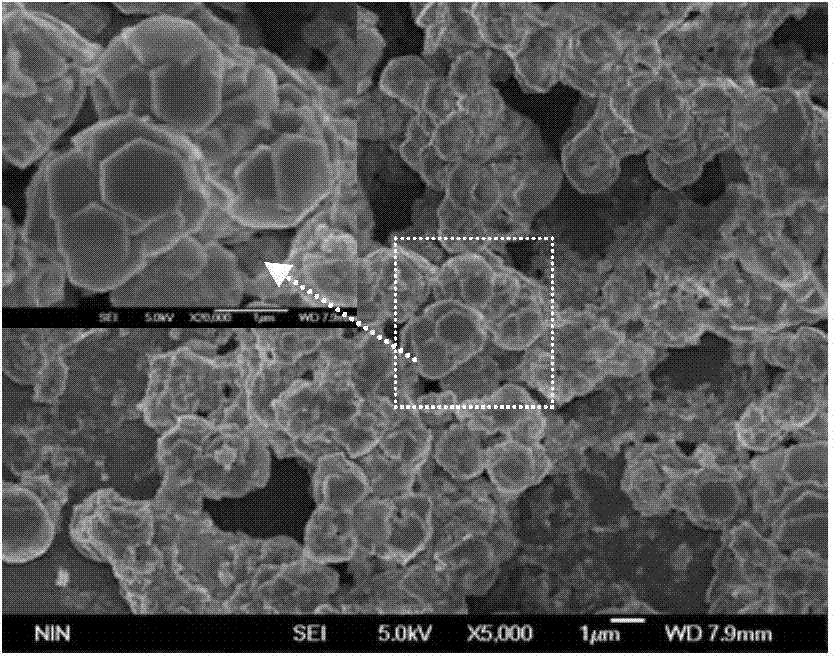

Method for preparing hexagonal piece self-assembled gamma-MnS microcrystalline spheres

A self-assembled, hexagonal sheet technology, applied in the field of preparation of γ-MnS microcrystalline spheres, can solve the problems of difficult process control, low reaction rate, long reaction time, etc., and achieve uniform size, low energy consumption, and short reaction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Analytical pure manganese nitrate (Mn(NO 3 ) 2 4H 2 O) added to deionized water to make Mn 2+ A transparent solution A with a concentration of 0.08mol / L;

[0018] 2) Add analytically pure thioacetamide (C 2 h 5 NS), so that the Mn in the solution 2+ / C 2 h 5 The molar concentration ratio of NS is 1:2, and the obtained solution B is uniformly stirred by magnetic force;

[0019] 3) adding analytically pure hexamethylenetetramine to solution B, so that the concentration of hexamethylenetetramine in the solution is 0.06mol / L, forming precursor solution C;

[0020] 4) Put the precursor solution C at room temperature for 1.5h to obtain solution D;

[0021] 5) Pour solution D into a microwave hydrothermal reactor with a filling degree of 48%, then seal the reactor, put it into a microwave hydrothermal reactor with temperature and pressure dual control, and select the temperature control mode or pressure control mode for reaction , the temperature in the temperatur...

Embodiment 2

[0025] 1) Analytical pure manganese nitrate (Mn(NO 3 ) 2 4H 2 O) added to deionized water to make Mn 2+ A transparent solution A with a concentration of 0.1mol / L;

[0026] 2) Add analytically pure thioacetamide (C 2 h 5 NS), so that the Mn in the solution 2+ / C 2 h 5 The molar concentration ratio of NS is 1:1, and the obtained solution B is uniformly stirred by magnetic force;

[0027] 3) adding analytically pure hexamethylenetetramine to solution B, so that the concentration of hexamethylenetetramine in the solution is 0.08mol / L to form precursor solution C;

[0028] 4) Put the precursor solution C at room temperature for 2 hours to obtain solution D;

[0029] 5) Pour solution D into a microwave hydrothermal reaction kettle with a filling degree of 50%, then seal the reaction kettle, put it into a microwave hydrothermal reaction instrument with dual temperature and pressure control, and select the temperature control mode or pressure control mode for reaction , the...

Embodiment 3

[0032] 1) Analytical pure manganese nitrate (Mn(NO 3 ) 2 4H 2 O) added to deionized water to make Mn 2+ A transparent solution A with a concentration of 0.5mol / L;

[0033] 2) Add analytically pure thioacetamide (C 2 h 5 NS), so that the Mn in the solution 2+ / C 2 h 5 The molar concentration ratio of NS is 1:5, and the obtained solution B is uniformly stirred by magnetic force;

[0034] 3) adding analytically pure hexamethylenetetramine to solution B, so that the concentration of hexamethylenetetramine in the solution is 1.5mol / L to form precursor solution C;

[0035] 4) Put the precursor solution C at room temperature for 1 hour to obtain solution D;

[0036] 5) Pour the solution D into the microwave hydrothermal reaction kettle with a filling degree of 55%, then seal the reaction kettle, put it into the microwave hydrothermal reaction instrument with dual temperature and pressure control, and select the temperature control mode or the pressure control mode for reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com