Borate fluorescent powder for white-light LED and preparation method of borate fluorescent powder

A borate and phosphor technology, applied in the field of borate phosphors and their preparation, can solve the problems of lack of trichromatic phosphors, color reabsorption, lumen efficiency and color rendering index effects, etc. The effect of good stability, simple manufacturing method and high color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

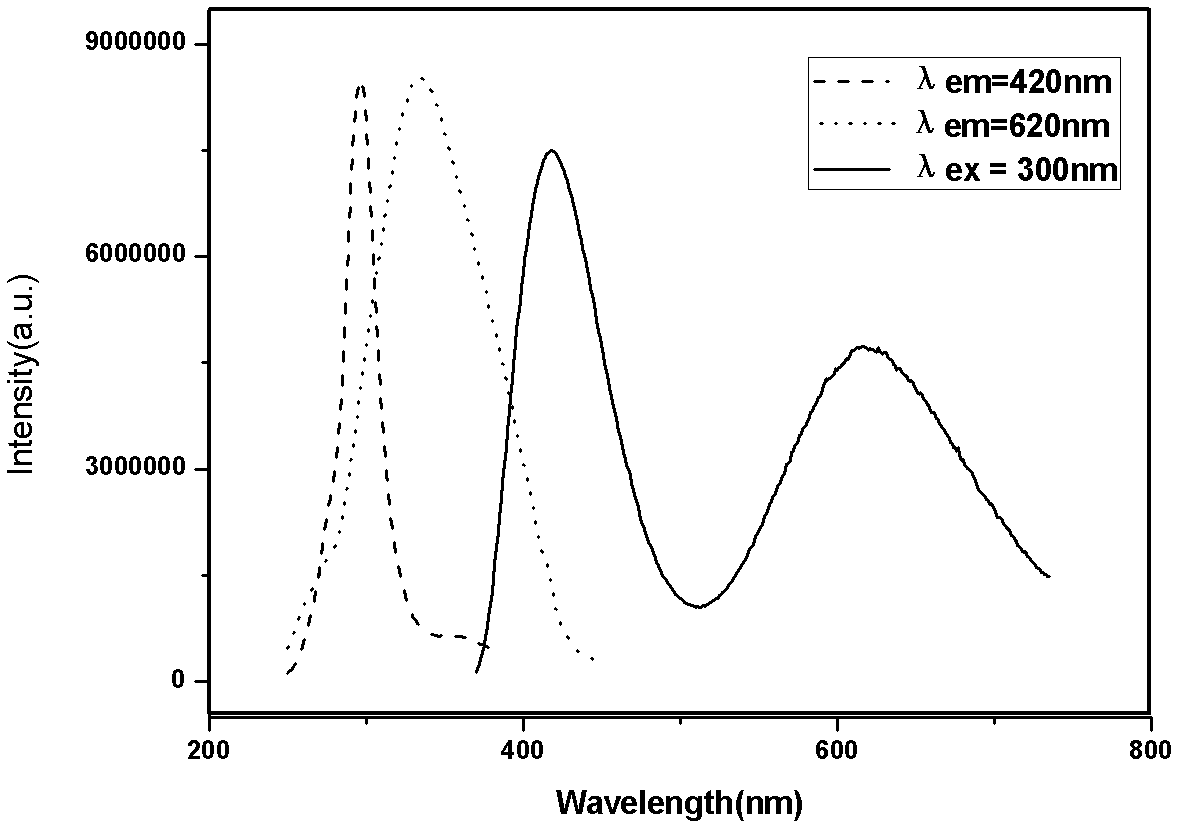

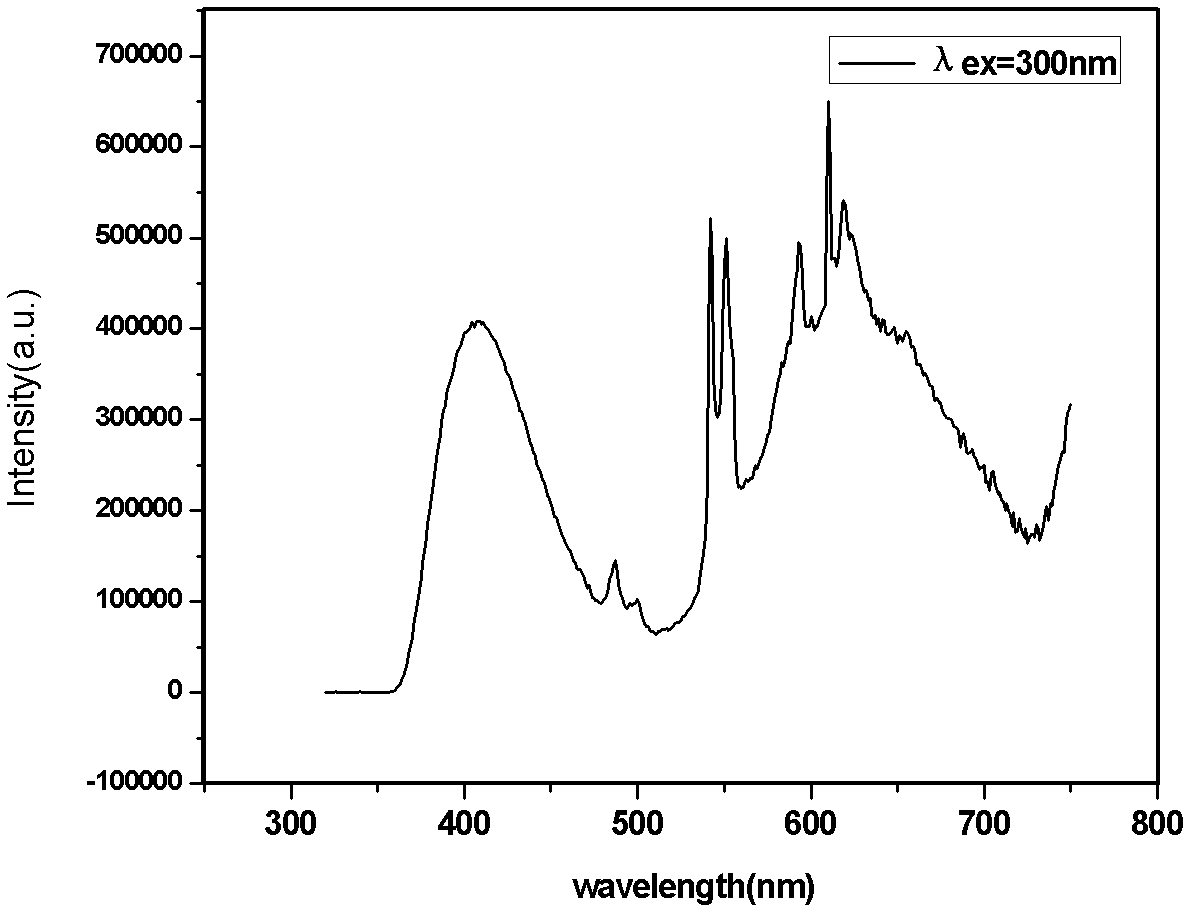

Image

Examples

Embodiment 1

[0026] Example 1: 1.87BaO 0.92MgO 1.00B 2 o 3 :0.03Eu 2+ , 0.05Ce 3+ , 0.05Na + Phosphor powder preparation. The preparation method is as follows:

[0027] Take by weighing 1.8452 grams of barium carbonate (BaCO 3 ), 0.1854 grams of magnesium oxide (MgO), 0.5874 grams of boric acid (H 3 BO 3 ), 0.0264 grams of europium trioxide (Eu 2 o 3 ), 0.0430 grams of cerium oxide (CeO 2 ), 0.0477 g of borax (Na 2 B 4 o 7 10H 2 O), the above raw materials are analytically pure. Put the above raw material mixture in an agate mortar, add 2mL of ethanol for grinding, after grinding evenly, put it into a corundum crucible, use the nitrogen mixture containing 5-10v% hydrogen as the reducing atmosphere, and the heating rate is 20°C / min. After reaching 1000°C, bake for 10 hours and cool down to room temperature naturally. The obtained sintered product is crushed, ball milled, and sieved to obtain a powder with a particle size of 3 to 10 microns, washed twice with deionized water ...

Embodiment 2

[0029] 1.66BaO 0.95MgO 1.50B 2 o 3 :0.08Eu 2+ , 0.06Ce 3+ , 0.03Tb 3+ , 0.09Na + Phosphor powder preparation.

[0030] The preparation method is as follows:

[0031] Weigh 1.2253 grams of strontium carbonate (SrCO 3 ), 0.1915 grams of magnesium oxide (MgO), 0.8718 grams of boric acid (H 3 BO 3 ), 0.0704 grams of europium trioxide (Eu 2 o 3 ), 0.0516 grams of cerium oxide (CeO 2 ), 0.0275 grams of terbium oxide (Tb 2 o 3 ), 0.0858 g of borax (Na2 B 4 o 7 10H 2 O), the above raw materials are analytically pure. Put the above raw material mixture in an agate mortar, add 2mL of ethanol to grind, after grinding evenly, put it into a corundum crucible, use the nitrogen mixture containing 5-10v% carbon monoxide as the reducing atmosphere, and the heating rate is 10°C / min, first Sinter at 800°C for 5 hours, then bake at 1100°C for 8 hours, and cool to room temperature naturally. Heat up after grinding, and roast according to the above conditions. After the sintered p...

Embodiment 3

[0033] 1.89BaO 0.87CaO 1.3B 2 o 3 :0.02Eu 2+ , 0.02Ce 3+ , 0.05Tb 3+ , 0.07Na + Phosphor powder preparation.

[0034] The preparation method is as follows:

[0035] Weigh 1.8650 grams of barium carbonate (BaCO 3 ), 0.4354 grams of calcium carbonate (CaCO3), 0.7605 grams of boric acid (H 3 BO 3 ), 0.0176 grams of europium trioxide (Eu 2 o 3 ), 0.0172 grams of cerium oxide (CeO 2 ), 0.0457 g terbium oxide (Tb 2 o 3 ), 0.0667 g of borax (Na 2 B 4 o 7 10H 2 O), the above raw materials are analytically pure. Put the above raw material mixture in an agate mortar, add 2mL of ethanol for grinding, after grinding evenly, put it into a corundum crucible, use the nitrogen mixture containing 5-10v% hydrogen as the reducing atmosphere, and the heating rate is 5°C / min, first Sinter at 800°C for 5 hours, then bake at 1200°C for 6 hours, and cool to room temperature. After the obtained sintered product is crushed, it is finely ground with a ball mill and sieved to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com