Current collector and preparation method thereof

A current collector, one-sided technology, applied in the field of current collectors and their preparation, can solve the problems of expansion and separation of active materials and current collectors, influence of cycle life battery safety performance, influence of interface resistance and bonding strength, etc., and achieve strong interaction force. , strong adhesion, enhance the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a current collector of a secondary battery, comprising: dispersing graphene and a binder in a solvent to form a slurry; coating the slurry on at least one surface of a current collector foil On, a coating layer containing graphene and a binder is formed; and then dried.

[0032] In order to make the coating have good electrical conductivity, as a preferred solution, the mass ratio of the graphene to the binder is (1-49): 1; the number of layers of the graphene is preferably between a single layer or 1-30 layers room, the layer is sp 2 Hybridized carbon atoms hexagonally closely packed, thin-layer carbon materials bonded by π bonds between layers; the carbon content of graphene is >95wt%, and the bulk conductivity is >100S / cm. The binder is preferably one or more of sodium carboxymethylcellulose, polyvinylidene fluoride, polytetrafluoroethylene, styrene-butadiene rubber and LA series binders.

[0033] In the pr...

Embodiment 1

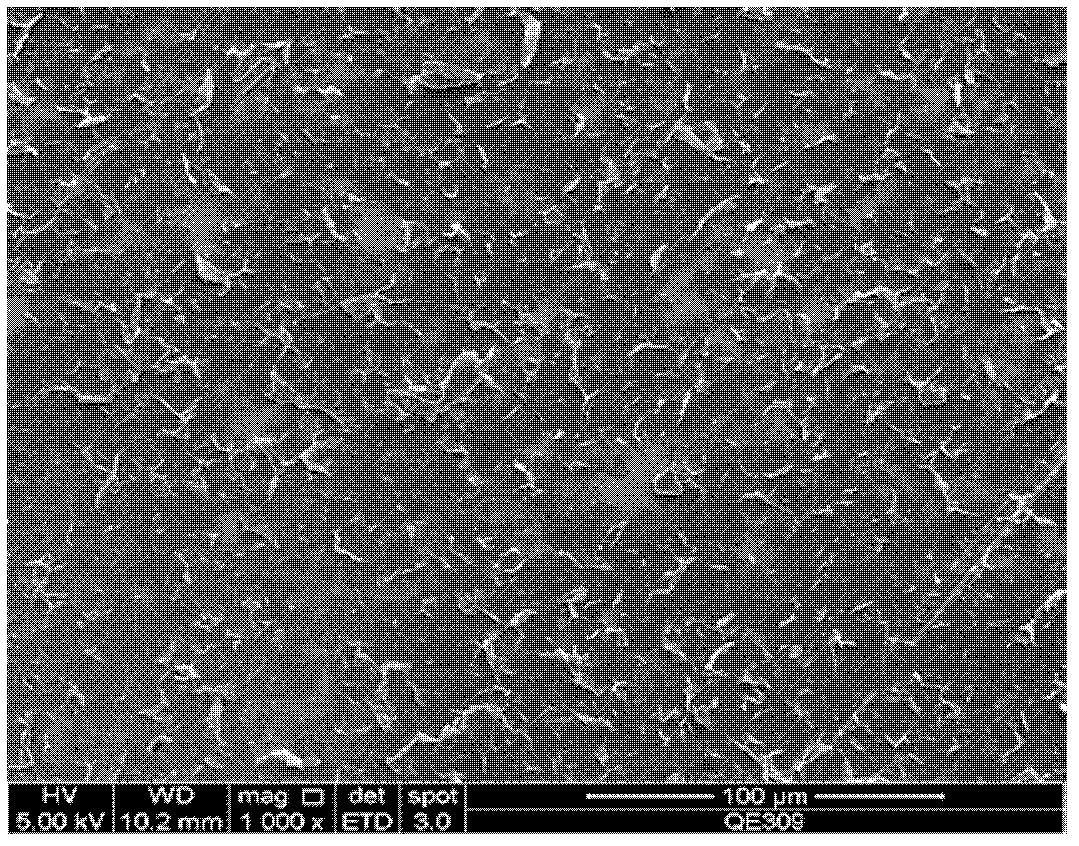

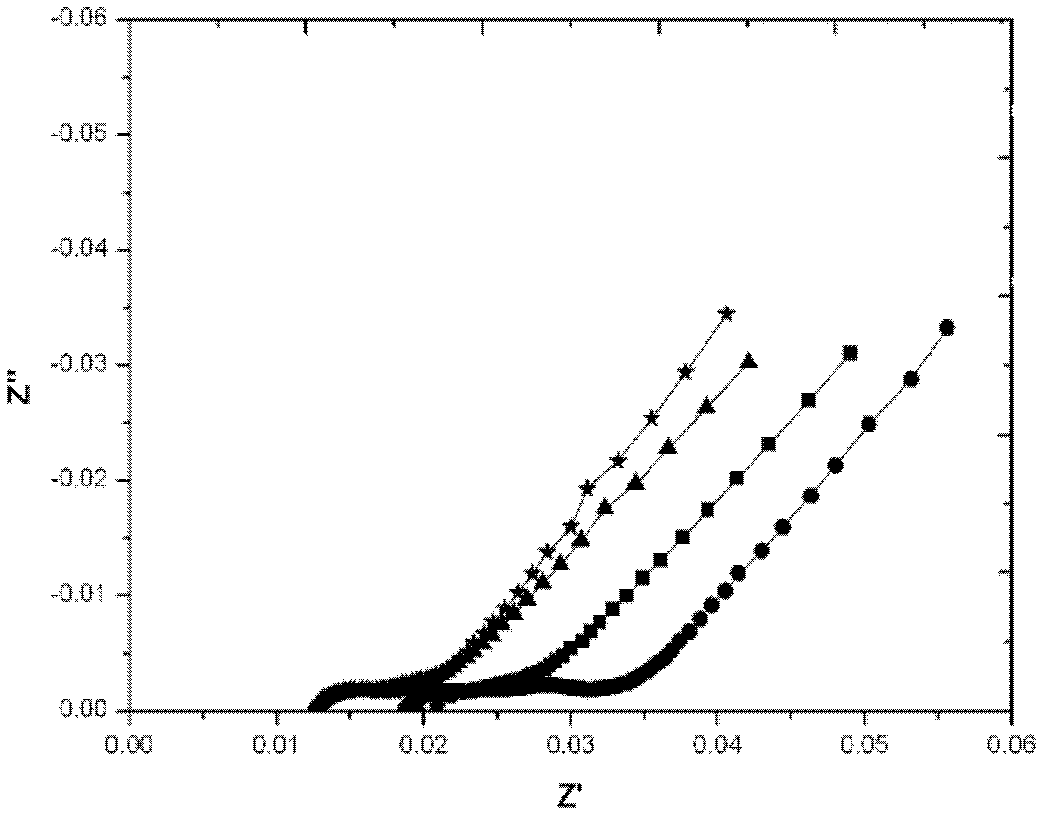

[0039] Weigh 2g of sodium carboxymethyl cellulose and add it to 1000g of deionized water, mix well with a mixer, then add 40g of graphene slurry, stir and mix evenly, the graphene slurry contains 8g of graphene, add 2000g of deionized water to adjust the slurry The viscosity of the material was controlled at 800mPa·s, and finally 30g of ethanol was added for low-speed vacuum stirring and defoaming treatment, and passed through a 150-mesh screen to obtain a slurry; the slurry was uniformly coated on the surface of the aluminum foil by a transfer coater, and Dry in a blast drying oven to obtain a graphene conductive coating with a single-sided coating thickness of 500 nanometers.

[0040] The obtained current collector was measured by a peel strength tester and the peel strength was 0.5N, and the resistivity of the electrode piece was tested by the four-point probe method was 4.553E. -6 ohm.cm.

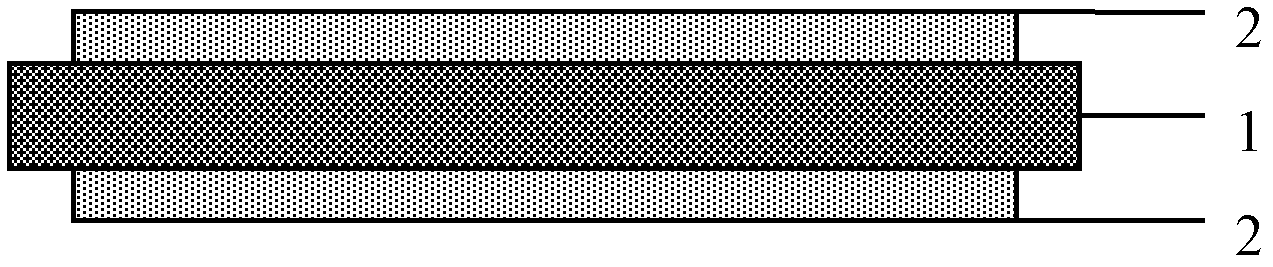

[0041] figure 1 It is a schematic structural diagram of the current collector pre...

Embodiment 2

[0044] Weigh 1.5g of sodium carboxymethylcellulose and add it to 1000g of deionized water, mix it with a mixer, and then add 30g of graphene slurry and 0.5g of conductive carbon black (Super P), stir and mix evenly, and the graphene slurry contains 8g graphene, add 2000g deionized water to adjust the viscosity of the slurry, the viscosity is controlled to 600mPa s, finally add 30g ethanol for low-speed vacuum stirring and defoaming treatment, and pass through a 150-mesh screen to obtain a slurry; The cloth machine is uniformly coated on the surface of the aluminum foil, and dried in a blast drying oven to obtain a graphene conductive coating with a single-sided coating thickness of 200 nanometers.

[0045] The obtained current collector was measured by a peel strength tester and the peel strength was 0.5N, and the resistivity of the electrode piece was tested by the four-point probe method was 4.761E. -6 ohm.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com