Matrix resin composition of resin-based fabric reinforced composite mandrel for overhead wire and application method of the resin composition

A fiber-reinforced composite, overhead wire technology, used in insulators, power cables, electrical components, etc., can solve problems such as failure to solve formula and manufacturing technical problems, and achieve high strength, good toughness, and good molding technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

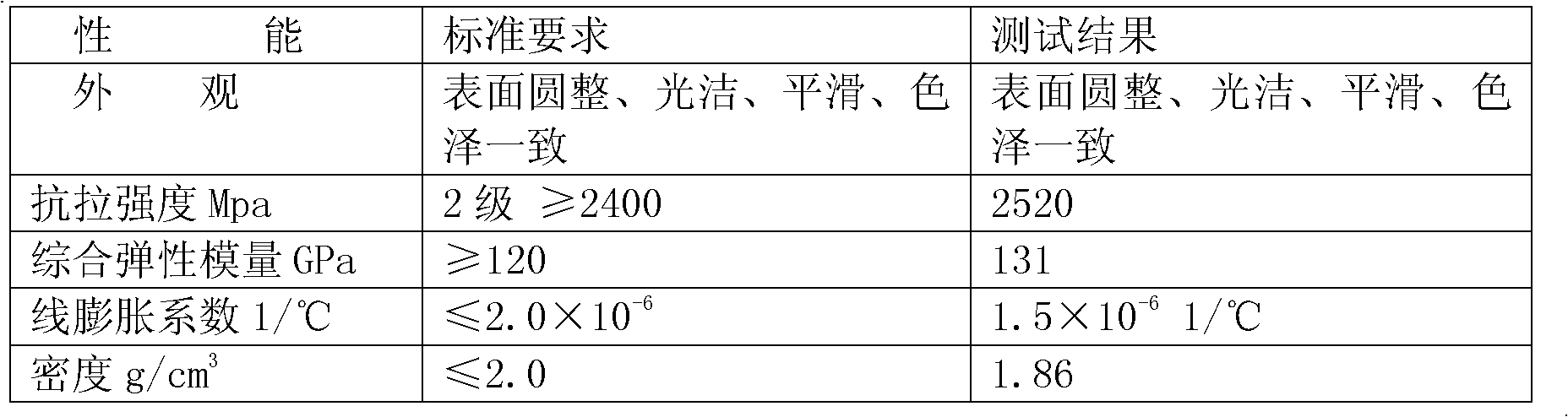

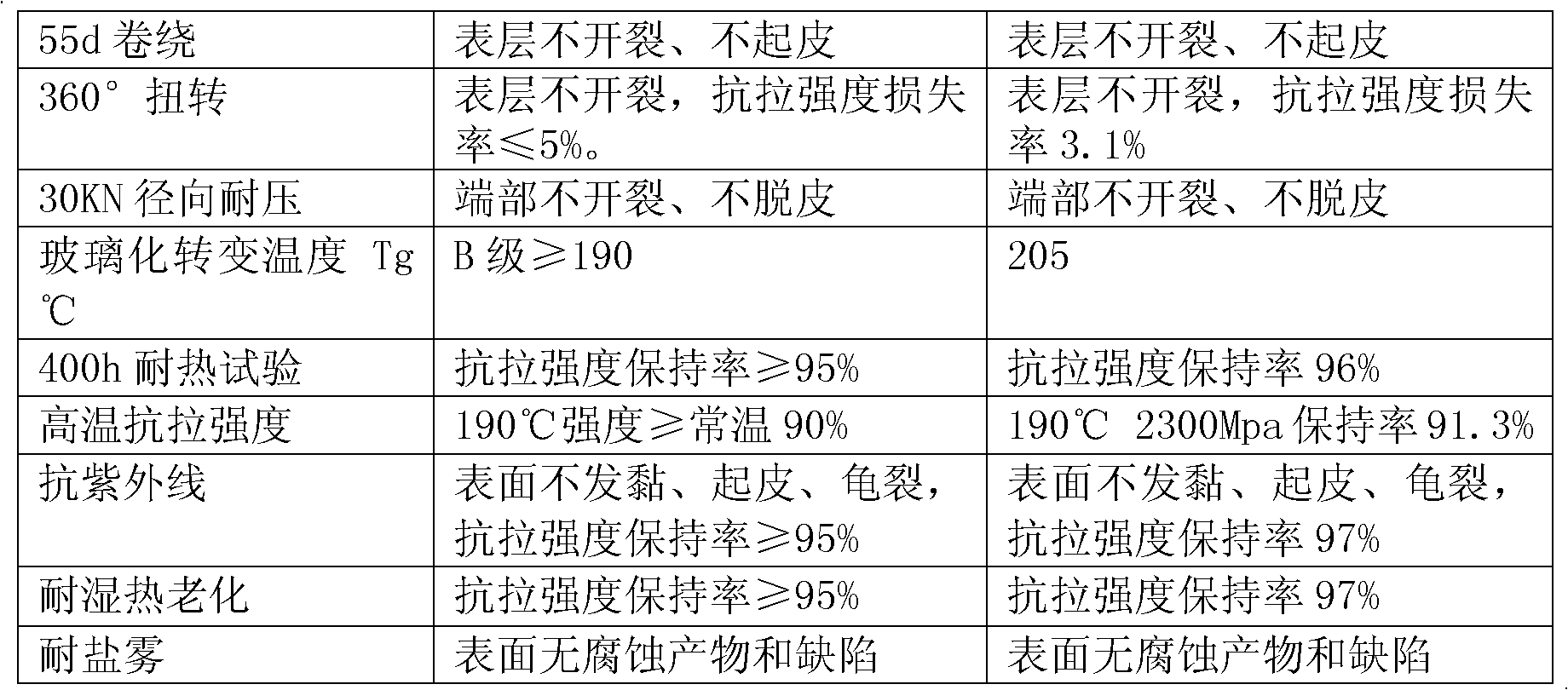

Examples

Embodiment 1

[0041] Put glycidylamine type epoxy resin (Changshu Jiafa Chemical Co., Ltd. JEh-012) 100kg in the stirred reactor, glycidylamine-ether type epoxy resin (Changshu Jiafa Chemical Co., Ltd. JEh-041) 40kg, defoamer A-530 (byk chemical) 0.1g, coupling agent KH-5601.5g, ultraviolet absorber UV-531 0.5kg, antioxidant 10102kg, carboxyl-terminated liquid nitrile rubber 15kg, at a speed of 80 to 100 rpm , 100~120°C, -0.1MPa defoaming and stirring for 1 hour, the discharge packaging is Class A, and the test viscosity is 11000mpa.s25°C.

[0042] Add 100kg of methyl nadic anhydride, 20kg of molecular weight 2000-3000 carboxyl-terminated polyacrylate, 2kg of modified imidazole (Changshu Jiafa Chemical JH-0511), and epoxide-treated nanopowder (Beijing Sublime Nanotechnology Co., Ltd. Company TMMT) 4kg, stirring to raise the temperature to 60-80°C, stirring and mixing for 1 hour at -0.1MPa, the output is Class B, and the test viscosity is 390mpa.s25°C.

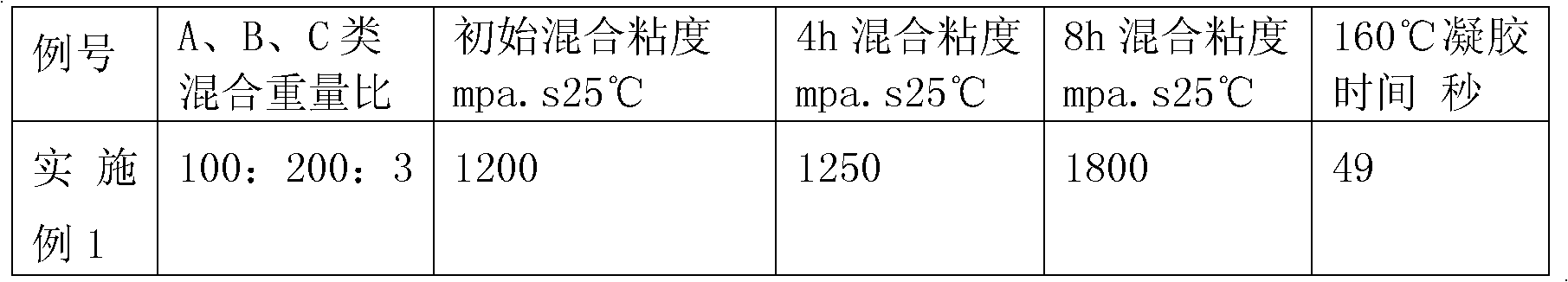

[0043] Stir and mix A, B, and C acco...

Embodiment 2

[0053] Put glycidylamine type epoxy resin ((Changshu Jiafa Chemical Co., Ltd. JEh-011) 100kg, alicyclic epoxy resin ERL-4206 (formerly American Union Carbide, now DOWCHEMICAL) 20kg, alicyclic epoxy resin in the stirred reactor Glycidyl ether type epoxy resin JEw-0211 (Changshu Jiafa Chemical Co., Ltd.) 20kg, defoamer A-530 (Germany BYK Chemicals) 0.1g, coupling agent KH-560 1.5g, ultraviolet absorber UV-531 0.5kg, 10102kg of antioxidant, 25kg of nano-powder rubber resin dispersion (resin content 40%), defoaming and stirring for 1 hour at a rotating speed of 80 to 100 rpm, 100 to 120°C and -0.1MPa, and the discharge package is as A Class, the test viscosity is 10200mpa.s25℃.

[0054] B and C are similar to Example 1, stirred and mixed according to the amount ratio of substances 100:135:2, the initial viscosity of the test is 1150mpa.s25°C, 1200mpa.s25°C after 4 hours, 1500mpa.s25°C after 8 hours, 160 The gel time at ℃ is 56 seconds, which shows that the viscosity of the matrix...

Embodiment 3

[0058] Make epoxy vinyl resin by following method; Drop into glycidylamine-ether type epoxy resin ((Changshu Jiafa Chemical Co., Ltd. JEh-022) 100kg, methacrylic acid 58kg, polymerization inhibitor terephthalic acid in the stirred reactor Phenol 0.1kg, triphenylphosphine 0.5kg, react at 100-120°C for 8 hours, drop the temperature at 80°C, add 70kg of trimethylol triacrylate, stir evenly to obtain epoxy vinyl resin. Put glycidylamine- Ether type epoxy resin ((Changshu Jiafa Chemical Co., Ltd. JEh-021) 100kg, the above-mentioned epoxy vinyl resin 40kg, defoamer A-530 (Germany BYK Chemicals) 0.1g, coupling agent KH-5601.5g, Ultraviolet absorber UV-531 0.5kg, antioxidant 1010 2kg, acrylate polymer 20kg with a molecular weight of 2000-3000, defoaming and stirring for 1 hour at a speed of 80-100 rpm, 100-120°C, -0.1MPa, and The material packaging is Class A, and the test viscosity is 8900mpa.s25℃.

[0059] B, C are similar to Example 1, according to the amount of substance ratio 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com