Brewing yeast strain capable of metabolizing xylose

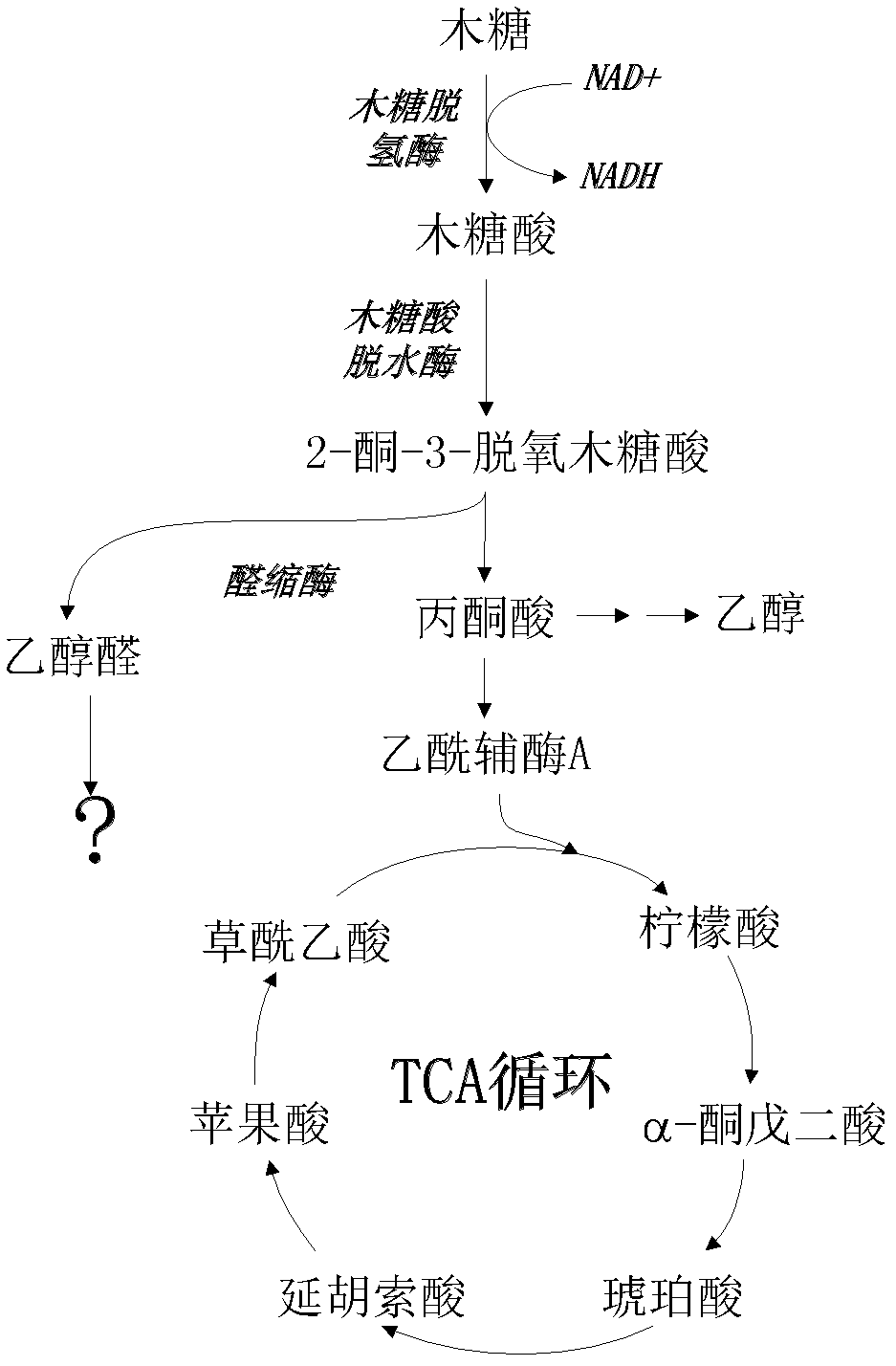

A Saccharomyces cerevisiae strain and technology of Saccharomyces cerevisiae, applied in fungi, microorganism-based methods, microorganisms, etc., can solve the problems of cumbersome pathways, insufficient xylose conversion efficiency, low efficiency, etc., and achieve the effect of short metabolic pathways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

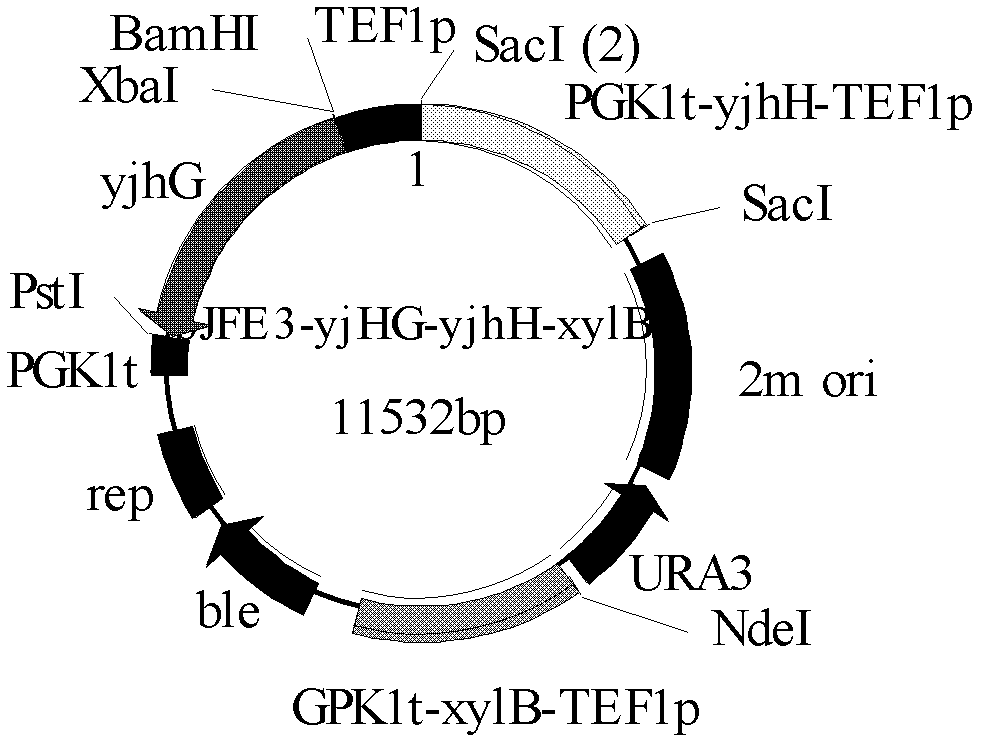

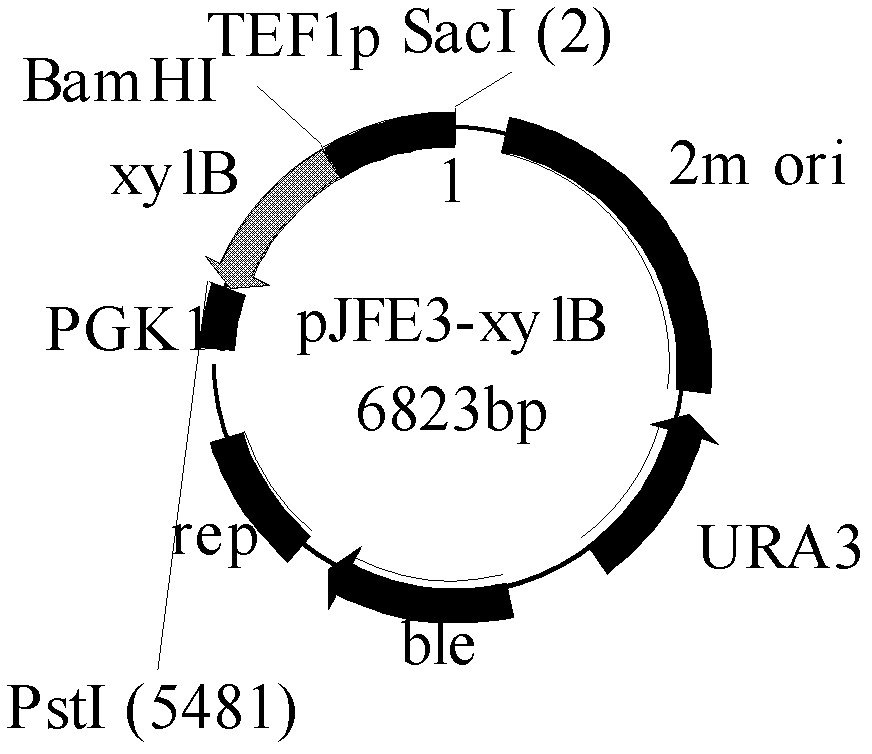

[0025] Embodiment 1: Construction of recombinant plasmid

[0026] Methods as below:

[0027] (1) Artificially synthesize its DNA according to the sequence of the xylose dehydrogenase gene (Cc-xylB) of Caulobacter crescentus; and use this DNA as a template, and use the nucleotide sequence of XF (XF as SEQ ID No. 2): 5'-GTACGGATCCATGTCCTCAGCCATCTATCC-3' and XR (the nucleotide sequence of XR is shown in SEQ ID No.3): 5'-TGACCTGCAGTCAACGCCAGCCGGCGTCG-3' is a primer to amplify the Cc-xylB fragment; The amplified fragment was restricted by restriction endonucleases BamHI and PstI, and ligated between the TEF1p promoter and PGK1t terminator of the episomal plasmid pJFE3 (use restriction endonucleases BamHI and PstI to restrict pJFE3 enzyme digestion), forming plasmid pJFE3-xylB ( image 3 ).

[0028] The above pJFE3

[0029] (2) Using Escherichia coli (Escherichia coli) chromosome as a template, GF (the nucleotide sequence of GF is shown in SEQ ID No.4): 5'-CAGGTCTAGAAGGAGAAACTC...

Embodiment 2

[0033] Embodiment 2: Construction of recombinant bacterial strain

[0034] (1) Inoculate the CEN.PK102-5B strain in YPD medium and culture overnight at 30°C;

[0035] (2) Transfer the CEN.PK102-5B culture medium cultured overnight to 50ml of fresh YPD, so that the initial OD 600 equal to 0.25, continue to culture at 30°C for about 4 hours to make the culture medium OD 600 equal to 0.7 to 1.0;

[0036] (3) Transform the plasmid pJFE3-yjhG-yjhH-xylB into the CEN.PK102-5B strain with lithium acetate transformation method, wherein, 50% polyethylenediene (PEG) 3350 is used as a protective agent, and single-stranded protist DNA is used for Vector for plasmid transformation.

[0037] (4) The transformed bacterial suspension was coated on a fully synthetic auxotrophic medium SC-Ura plate added with 20 g / L glucose, and transformants were picked.

[0038] (5) The xylose utilization performance of the transformants was tested in SC-Ura medium with 20 g / L xylose as the sole carbon sou...

Embodiment 3

[0040] Embodiment 3: Xylose fermentation of BSHH02B bacterial strain

[0041] Methods as below:

[0042] (1) Strain activation: Pick a single colony of the BSHH02B strain and inoculate it in a fully synthetic auxotrophic medium SC-Ura supplemented with 20g / L glucose, and cultivate it at 30°C and 200rpm for 24 hours; the above-mentioned culture was inoculated with 10% volume The amount was transferred to the fully synthetic auxotrophic medium SC-Ura (20g / L glucose as carbon source), and cultured at 30°C and 200rpm for 12 hours.

[0043] (2) Inoculation: the above activated bacterial solution was used as the strain, rinsed with sterile water and the initial OD 600 =0.1 was inoculated in a 1L fermentor containing 800ml of fully synthetic auxotrophic culture medium SC-Ura (20g / L xylose as carbon source); at 30°C, pH 5.0, ventilation of 0.5L / min, Fermentation was carried out under the condition of stirring speed.

[0044] (3) Determination of growth curve: after inoculation, ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com